Method for rapidly measuring material retention on paper making net

A rapid determination and retention rate technology, applied in measuring devices, analyzing materials, and analyzing materials through optical means, can solve problems such as time-consuming, low accuracy, and large errors, and achieve shortened test time, simplified operating procedures, The effect of reducing the error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1. Determination method of turbidity value

[0026] (1) Take a sample of netting paper material and papermaking white water, stir well and evenly, take 50ml each with a measuring cylinder, add 150ml of distilled water to dilute 4 times, shake well and set aside.

[0027] (2) Pour the above-mentioned prepared samples into the test sample pool in turn, add 2 drops of test stabilization solution, vibrate evenly, then drive away the air bubbles in the bottle, and then put them on the turbidimeter for testing, read after 10 seconds The result is an indirect measure of concentration.

[0028] (3) After finishing, shake well and repeat operation (2), each sample takes 3 valid data.

[0029] 2. Calculation of the actual concentration of the sample

[0030] Input all the tested data into the following regression equation or calculation software in turn, sample concentration c%. The actual value of the concentration can be obtained by calculating according to the following for...

Embodiment 2

[0041] 1. Method of testing light transmittance

[0042] (1) Take 1ml each of the paper stock and papermaking white water samples, dilute with 50ml distilled water, and then measure the light transmittance with a spectrophotometer.

[0043] (2) Repeat operation (1) after completion, and take 3 valid data for each sample.

[0044] 2. Calculation of the actual concentration of the sample

[0045] Input all the tested data into the following regression equation or calculation software in turn, sample concentration c%.

[0046] The actual value of the concentration can be obtained by calculating according to the following formula:

[0047] C%=-2.7551-3.5153*K 0 *log10(T / 100)

[0048] In the formula, K 0 is the experimental constant

[0049] T is light transmittance

[0050] 3. Calculate retention rate

[0051] Put the concentration values of each sample above into the formula:

[0052] SPR%=(c1-c2)*100% / c1

[0053] In the formula, c1 is the concentration of the upper f...

Embodiment 3

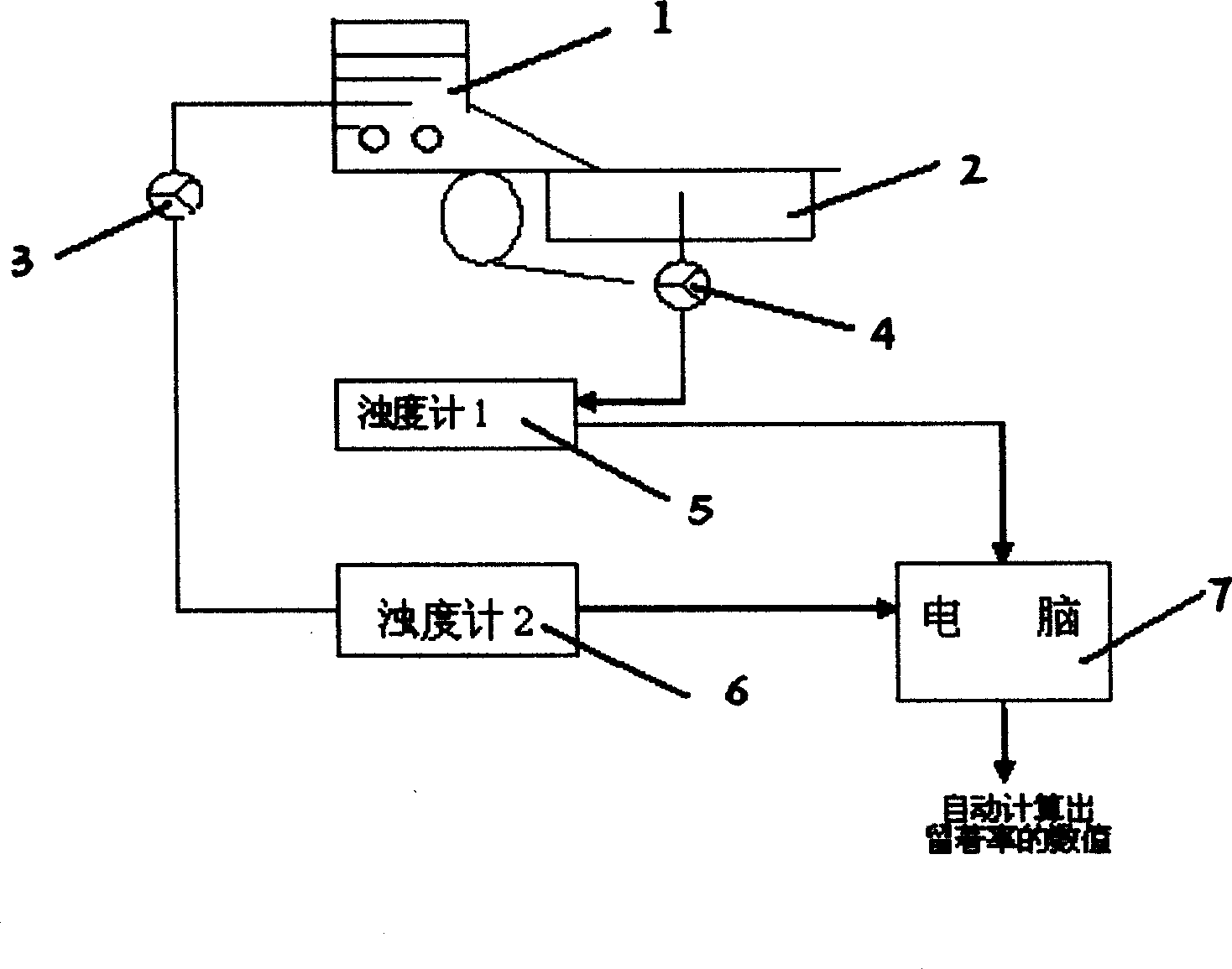

[0056] On-line sampling through the online sampling device, the sample taken automatically enters the detection instrument for measurement. After the measurement, the data is collected by the computer and the retention rate is calculated.

[0057] The process is shown in the attached figure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com