Silencer for adsorption-based gas separation systems

一种消音器、吸收室的技术,应用在消音装置、用于弹性流体的泵送装置的部件、机器/发动机等方向,达到简单内部构造、消除钢壳振动问题、低压降的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

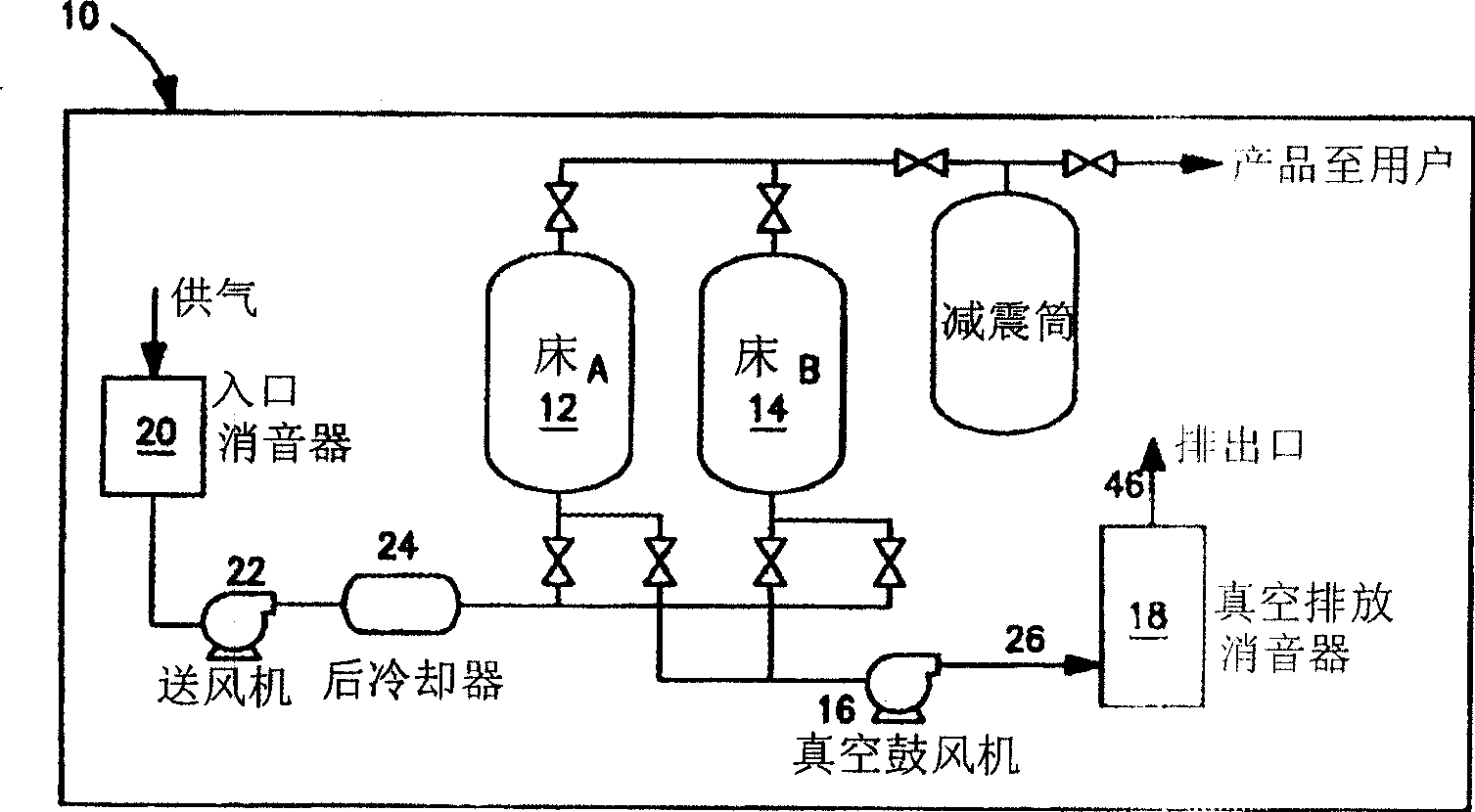

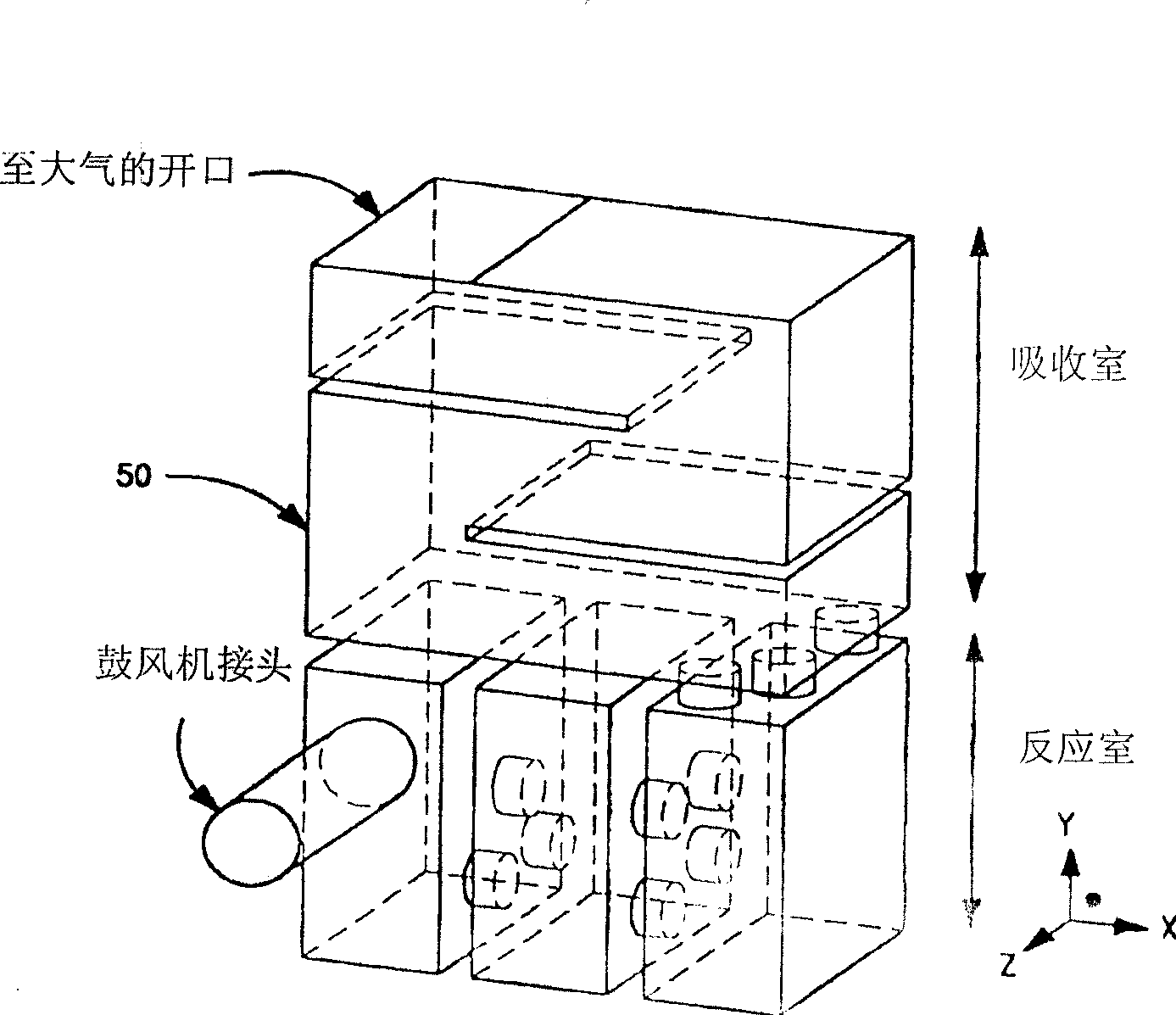

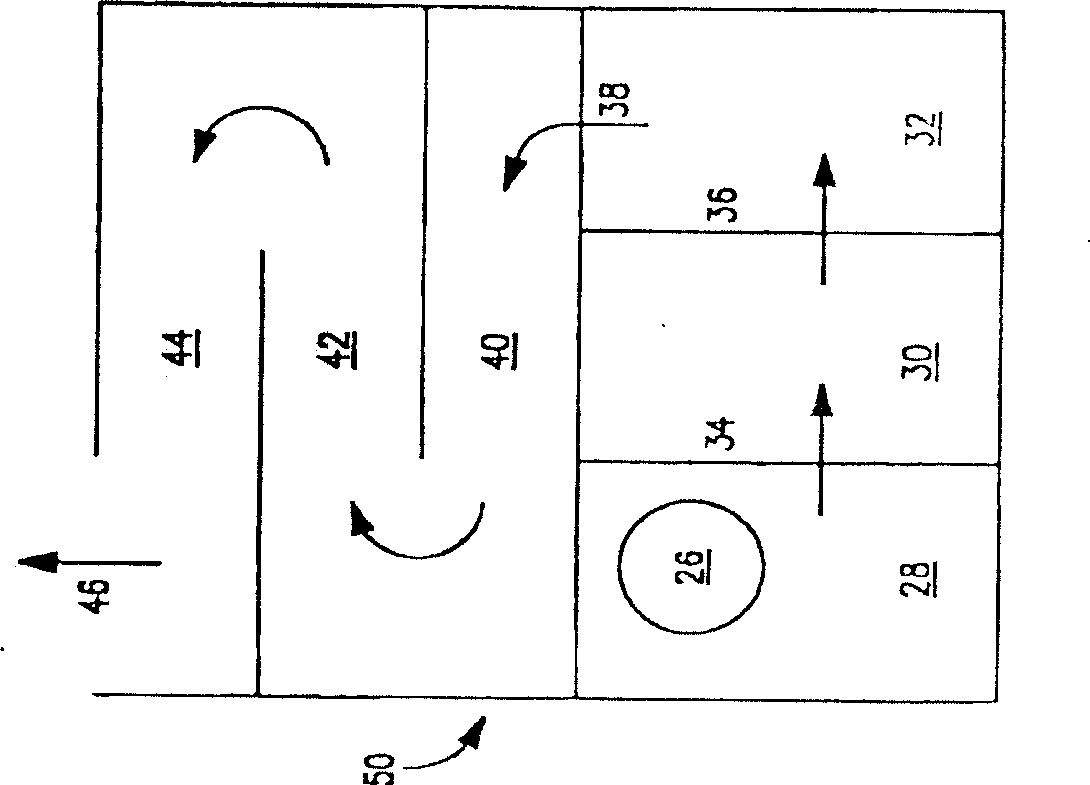

[0027] As described above, the present invention relates to attenuation of noise of a vacuum blower using a silencer. More specifically, the present invention provides a low cost, reliable and efficient muffler that can reduce noise levels to approximately 90 dBA. In an exemplary embodiment of the invention, the muffler can be used at the discharge of a vacuum blower in a large tonnage oxygen vacuum pressure swing adsorption (oxygen VPSA) plant. The muffler includes a reaction chamber for attenuating low frequency vibrations and an absorption chamber for attenuating middle and high frequency noises.

[0028]The inner and outer walls of the muffler are composed of concrete, including reinforced concrete (eg, reinforced concrete). However, other materials of construction may also be suitable for use in the present invention. Bricks and / or masonry blocks may be used, for example, but are not to be construed as limited thereto. In addition, the materials of construction of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com