Toroidal flow shaping method of antisymmetric reducing thin wall part

A thin-walled parts, evenly distributed technology, applied in the field of asymmetric variable-diameter thin-walled parts forming, can solve the problems of inability to realize asymmetrical variable-diameter thin-walled parts forming, inability to adjust the unevenness of blanks, etc. The effect of good surface quality and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

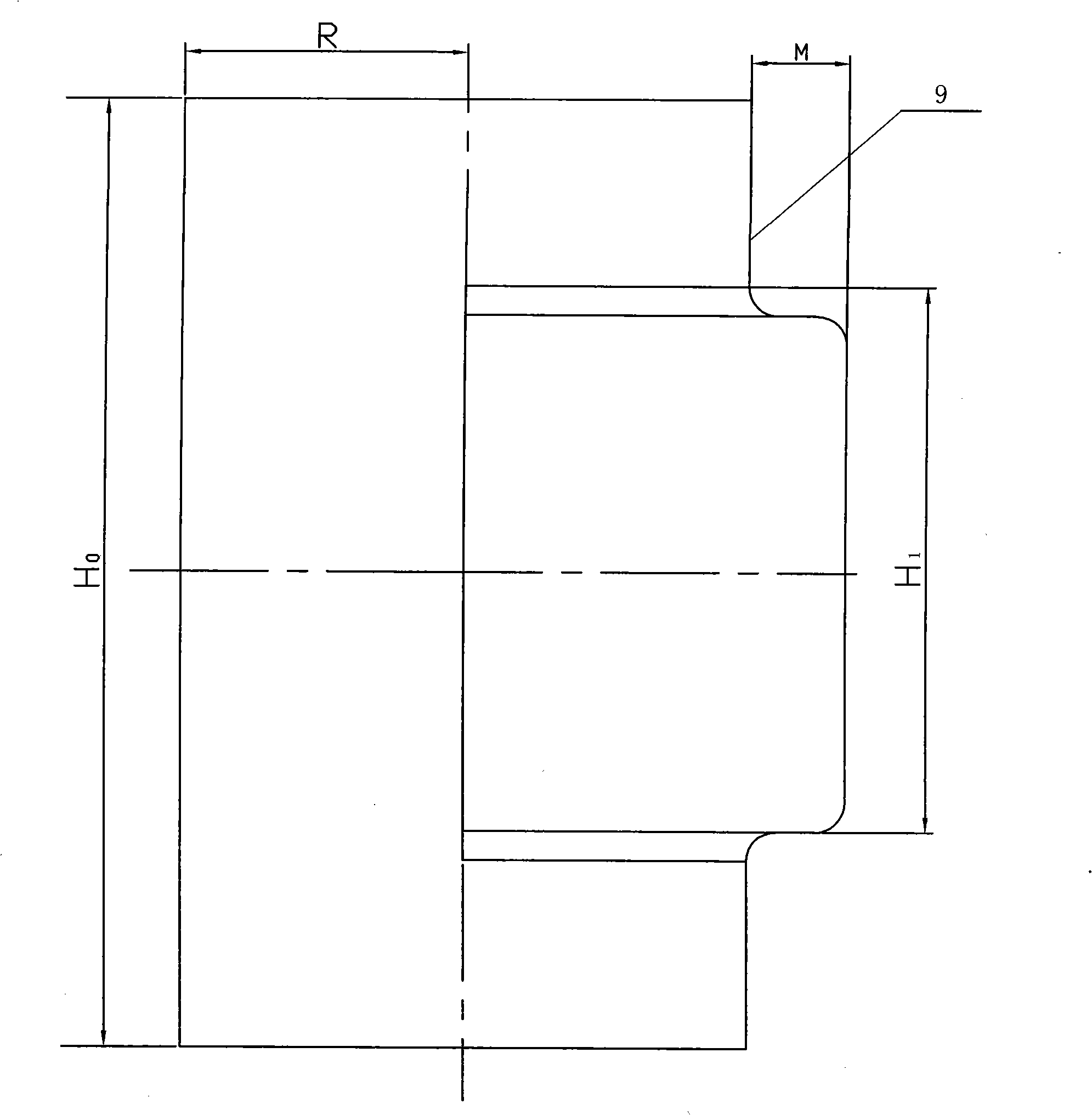

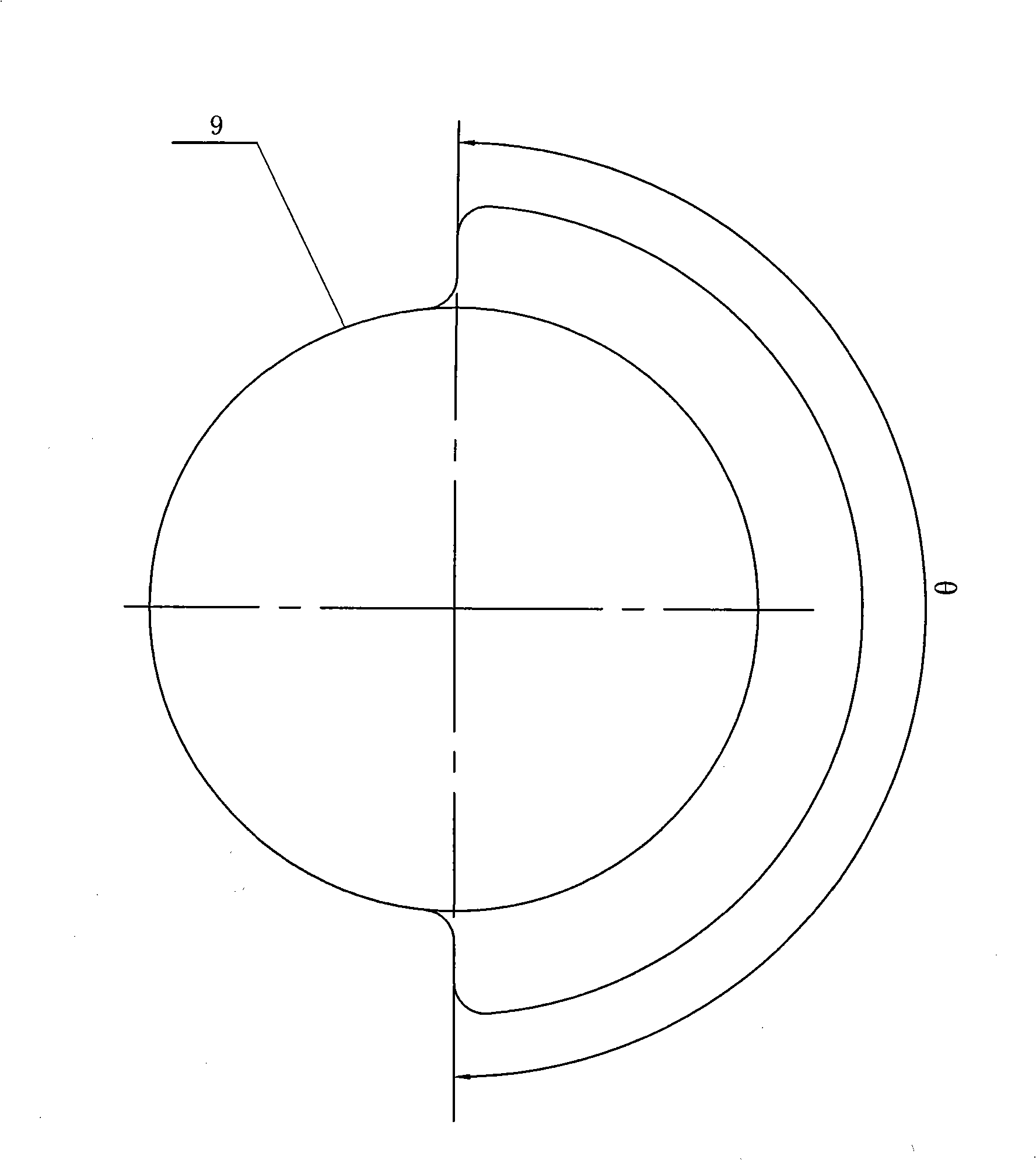

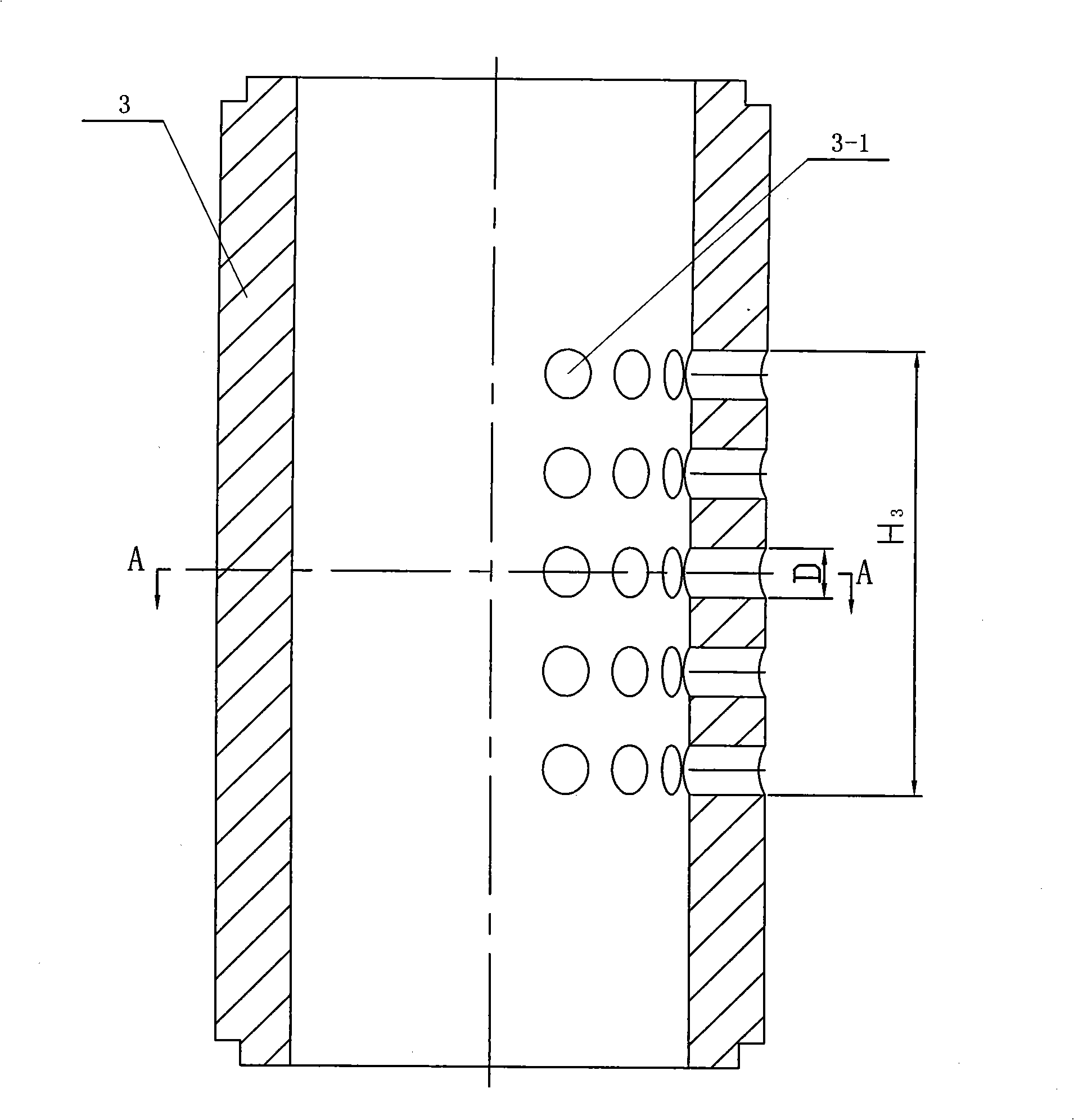

[0013] Specific implementation mode one: combine Figure 1 to Figure 12 Describe this embodiment, the thin-walled parts circular flow forming method with uniform distribution of asymmetrical variable diameter in this embodiment is realized in this way: using viscoelastic plastic soft mold forming method, step 1, according to the asymmetrical variable diameter The structural characteristics of the thin-walled parts 9, the structural design of the core mold 3 in the forming mold 10: at a height of H 3 1. A plurality of loading injection holes 3-1 are processed on the side wall of the mandrel 3 in the region where the included angle in the horizontal section is α, and the diameter D of each loading injection hole 3-1 is 8 mm to 15 mm. Height H 3 and the included angle α are:

[0014] h 3 =H 1 -(8~12)mm(1)

[0015] Among them: H 1 is the forming height of the asymmetric variable-diameter thin-walled part 9, mm;

[0016] α=θ-(8°~12°)(2)

[0017] Where: θ is the horizontal i...

specific Embodiment approach 2

[0019] Embodiment 2: The slab blank in step 2 of this embodiment is stainless steel, titanium alloy, nickel-based superalloy or iron-based superalloy. The asymmetric variable-diameter thin-walled parts made of the above-mentioned materials can fully meet the needs of the fields of automobiles, aviation and spaceflight. Other method steps are the same as those in the first embodiment.

specific Embodiment approach 3

[0020] Embodiment 3: The difference between this embodiment and Embodiment 2 is that the grade of the stainless steel in this embodiment is 1Cr18Ni9Ti or 0Cr18Ni9Ti. The asymmetric variable-diameter thin-walled parts made of the above-mentioned materials can fully meet the needs of the fields of automobiles, aviation and spaceflight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com