Corrugated continuous reinforced plastics heat-preserving composite pipe

A reinforced plastic and thermal insulation composite technology, which is used in thermal insulation and protection of pipelines and pipes through thermal insulation, can solve the problems of pipelines that cannot withstand circumferential pressure, many thermal insulation pipe joints, and extruded thermal insulation materials, so as to improve the resistance to external pressure. Effect, fast construction, small bending radius effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

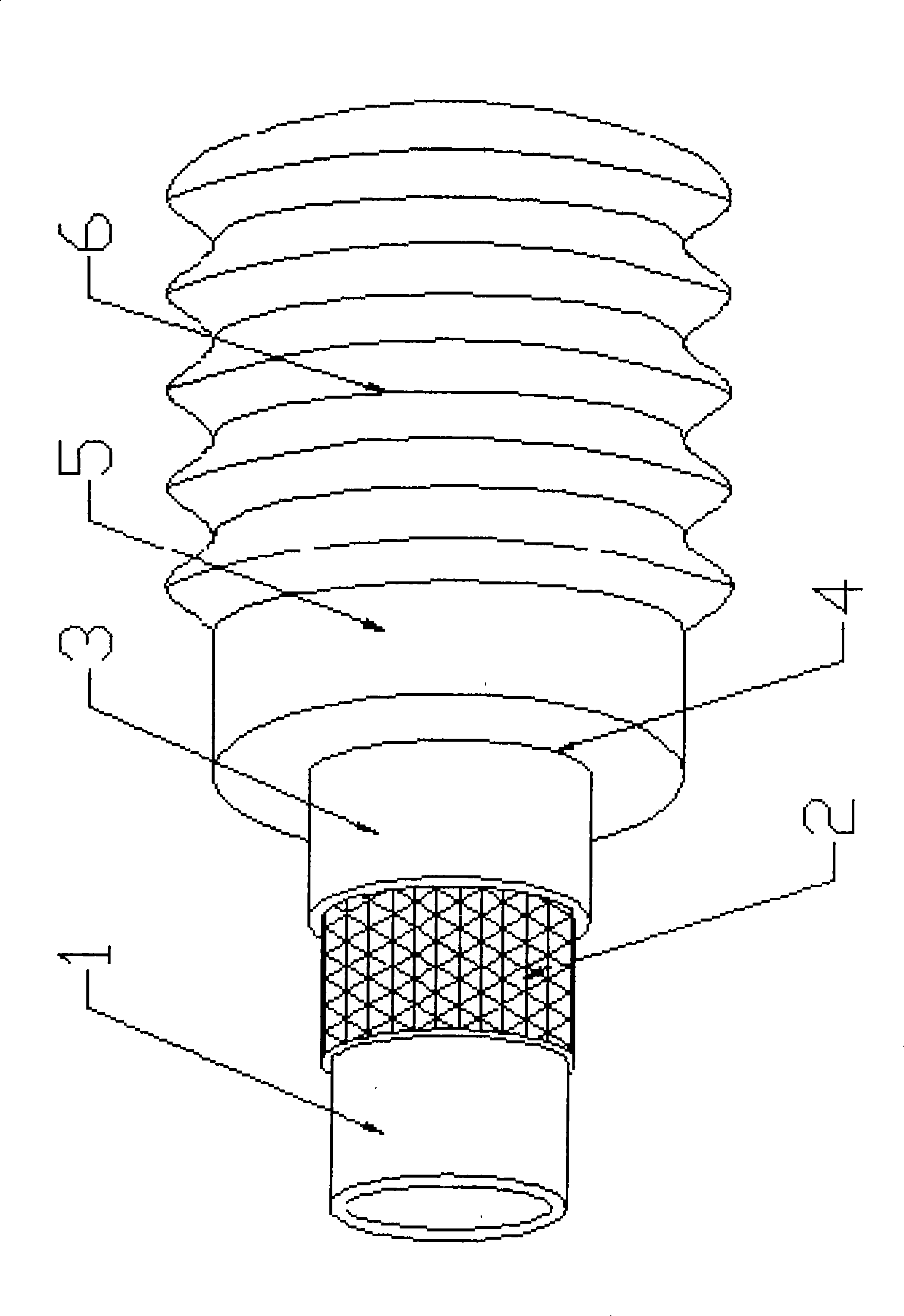

[0033] Embodiments of the present invention are described as follows in conjunction with the accompanying drawings:

[0034] One or more layers of steel wires are braided on the conveying layer 1 to form the reinforced layer 2; the reinforced layer 2 is covered with a polyethylene protective layer 3; a layer of thermoplastic elastomer solvent-based adhesive is uniformly coated on the protective layer 3 Adhesive to form an adhesive layer 4; on the adhesive layer 4, the closed-cell foamed cross-linked polyethylene insulation layer 5 is longitudinally and continuously wrapped by a continuous insulation coating machine; Shaped protective layer 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com