Pharmaceutical composition containing gliclazide

A Glichetide and composition technology, applied in the field of sustained-release pharmaceutical compositions, can solve problems such as poor water solubility and incomplete release of the main drug, and achieve the effect of increasing water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] This embodiment is made into a solid dispersion first and then into a sustained-release tablet

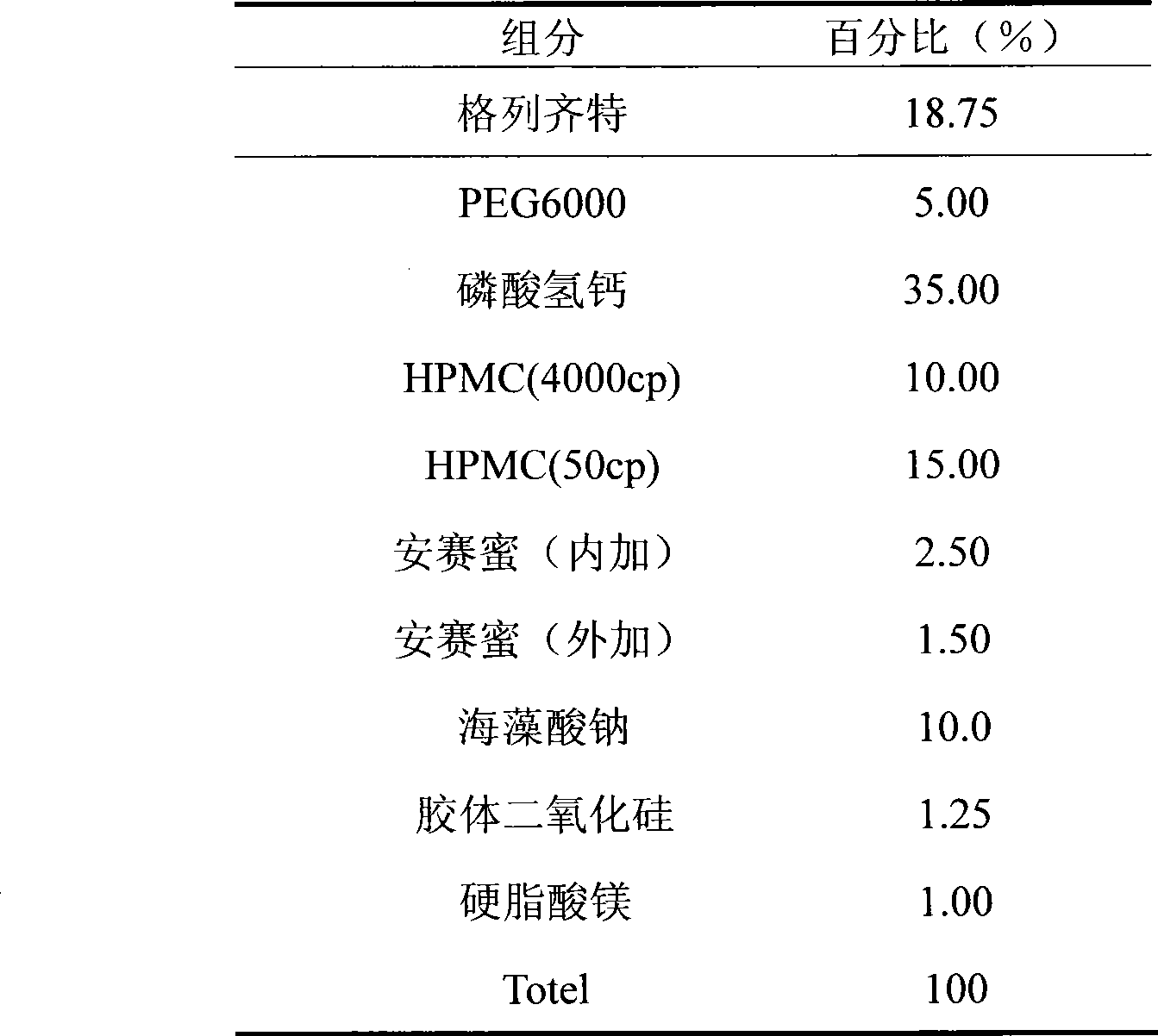

[0015]

[0016] Preparation process: weigh gliclazide and PEG6000 according to the prescription amount, use 95% ethanol solution as a binder, add hypromellose, and wet granulate with 60 mesh. Dried at 50°C, crushed and stirred with calcium hydrogen phosphate, sodium alginate, acesulfame potassium and colloidal silicon dioxide to dissolve, 30 mesh wet granulation, and dried at 60°C. Whole grains with 26 meshes, measure the water content, add magnesium stearate and acesulfame potassium, mix, and compress into tablets at 60-80N.

Embodiment 2

[0018] This embodiment is made into a solid dispersion first and then into a sustained-release tablet

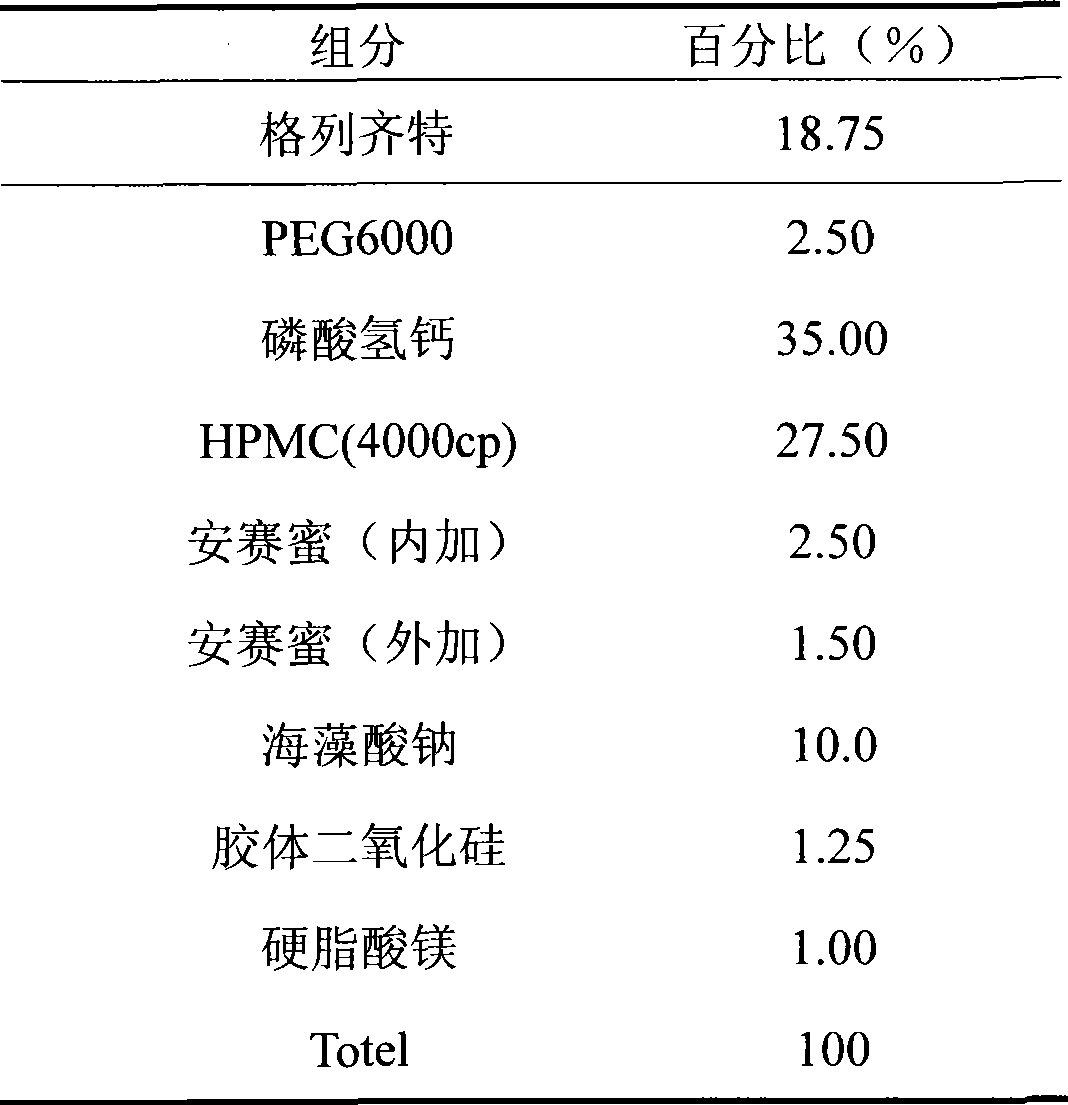

[0019]

[0020] Preparation process: weigh gliclazide and PEG6000 according to the prescription amount, use 95% ethanol solution as a binder, add hypromellose, and wet granulate with 60 mesh. Dried at 50°C, crushed and stirred with calcium hydrogen phosphate, sodium alginate, acesulfame potassium and colloidal silicon dioxide to dissolve, 30 mesh wet granulation, and dried at 60°C. Whole grains with 26 meshes, measure the water content, add magnesium stearate and acesulfame potassium, mix, and compress into tablets at 60-80N.

Embodiment 3

[0022] This embodiment mode directly makes sustained-release tablet as

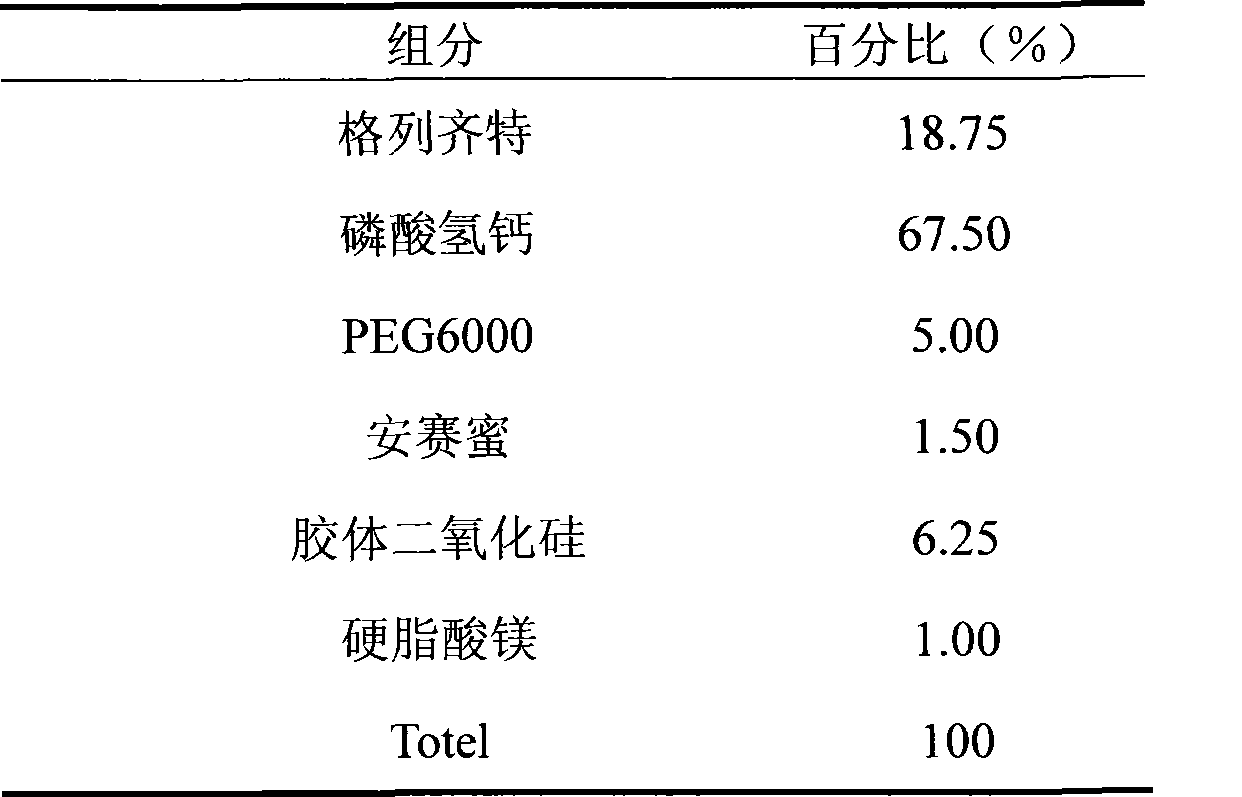

[0023]

[0024] Preparation process: Weigh gliclazide, calcium hydrogen phosphate and PEG6000 according to the prescription, use 95% ethanol solution as a binder, add acesulfame potassium and colloidal silicon dioxide and stir to dissolve them, 30 mesh wet granulation, Dry at 60°C. The granules are sized at 26 mesh, the water content is measured, magnesium stearate is added and mixed, and then pressed into tablets at 60-80N.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com