Method for producing nano particle with lamination structure

A nanoparticle and layered structure technology, applied in the direction of nanotechnology, nanotechnology, nanostructure manufacturing, etc., can solve the problems of increased manufacturing costs and restrictions on the insertion of guest materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

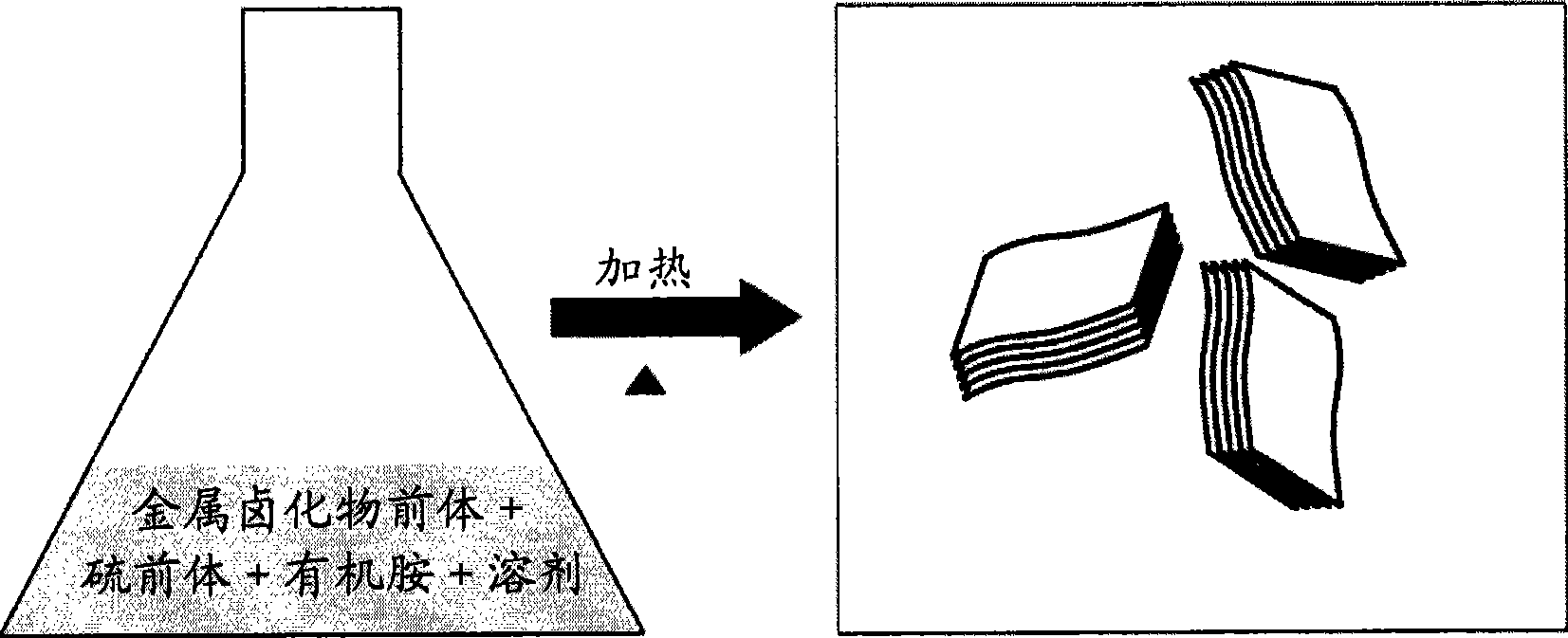

Method used

Image

Examples

no. 1 approach

[0073] Preparation of TiS 2 nanoparticle approach

[0074] First, 90 μl of TiCl 4 and 3 g of refined oleylamine were put into a flask, and then heated at a temperature of 300° C. in an argon atmosphere. At this temperature, 0.12 ml of carbon disulfide was mixed. Then, the liquid mixture was heated at a temperature of 300°C.

[0075] After the liquid mixture was maintained at 300° C. for 30 minutes, the liquid mixture was cooled to normal temperature, and then 20 ml of acetone was added to precipitate layered structure nanoparticles. The precipitated layer-structured nanoparticles were collected using a centrifugal separator.

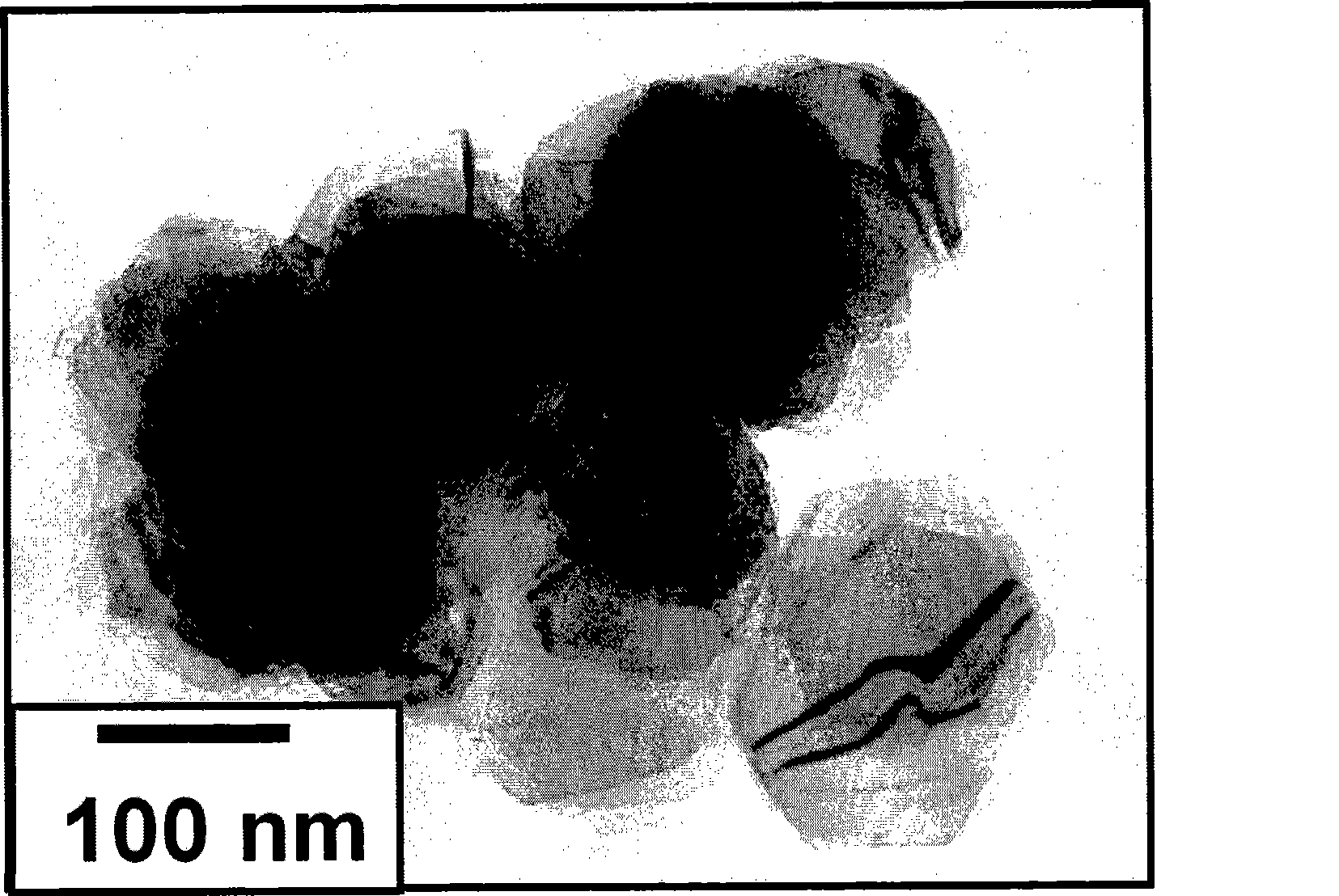

[0076] Then, 20 μl containing the collected TiS 2 The solution of nanoparticles was dropped onto a TEM grid coated with a carbon grid and dried for about 20 minutes. Then, observation was performed by a transmission electron microscope (EF-TEM) (Zeiss, accelerating voltage: 100 kV). figure 2 Observations are shown.

[0077] like figure 2...

no. 2 approach

[0088] Preparation of ZrS 2 nanoparticle approach

[0089] Prepare ZrS by the same method as the first embodiment 2 nanoparticles. In this embodiment, using ZrCl 4 instead of TiCl 4 in order to produce ZrS 2 nanoparticles.

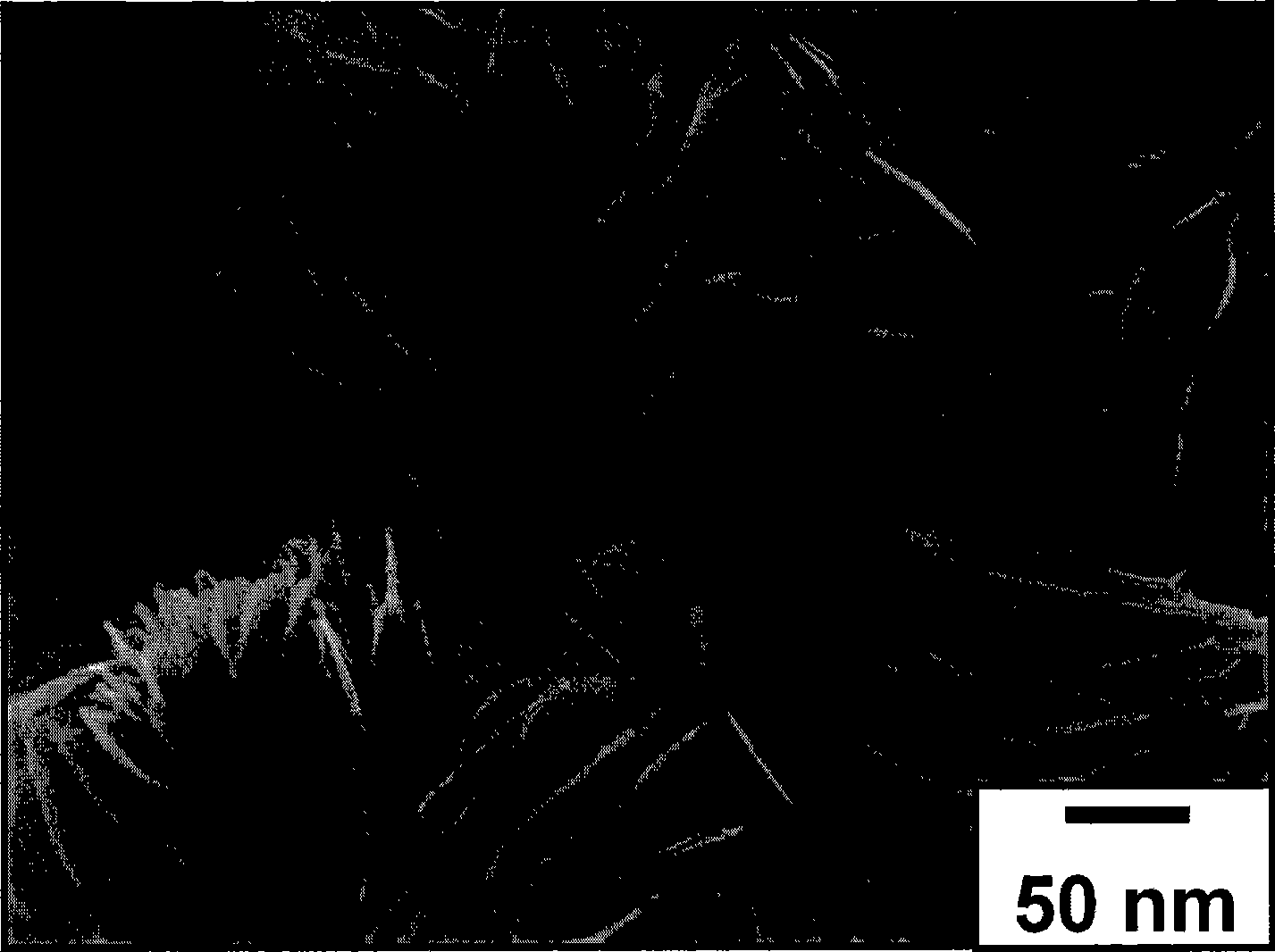

[0090] Figure 7 shows that ZrS prepared in such a way 2 TEM observation of nanoparticles.

no. 3 approach

[0092] Prepare WS 2 nanoparticle approach

[0093] WS is prepared by the same method as the first embodiment 2 nanoparticles. In this embodiment, using WCl 4 instead of TiCl 4 in order to generate WS 2 nanoparticles.

[0094] Figure 8 shows that WS prepared in such a way 2 TEM observation of nanoparticles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com