Fuel cell system

A fuel cell system and fuel cell technology, applied in fuel cells, fuel cell additives, transportation fuel cell technology, etc., can solve problems such as inability to start the machine, poor startability, piping, and valve damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

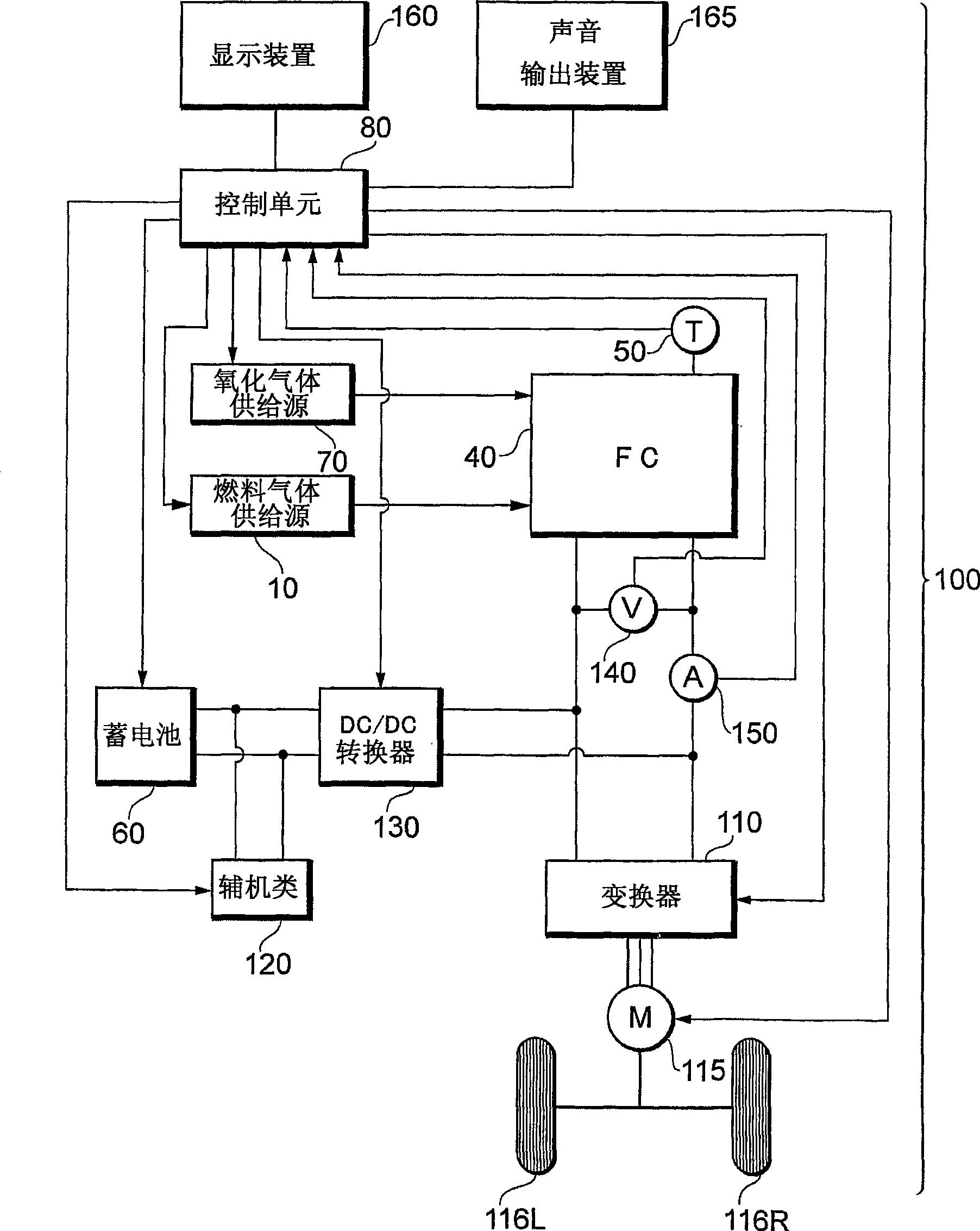

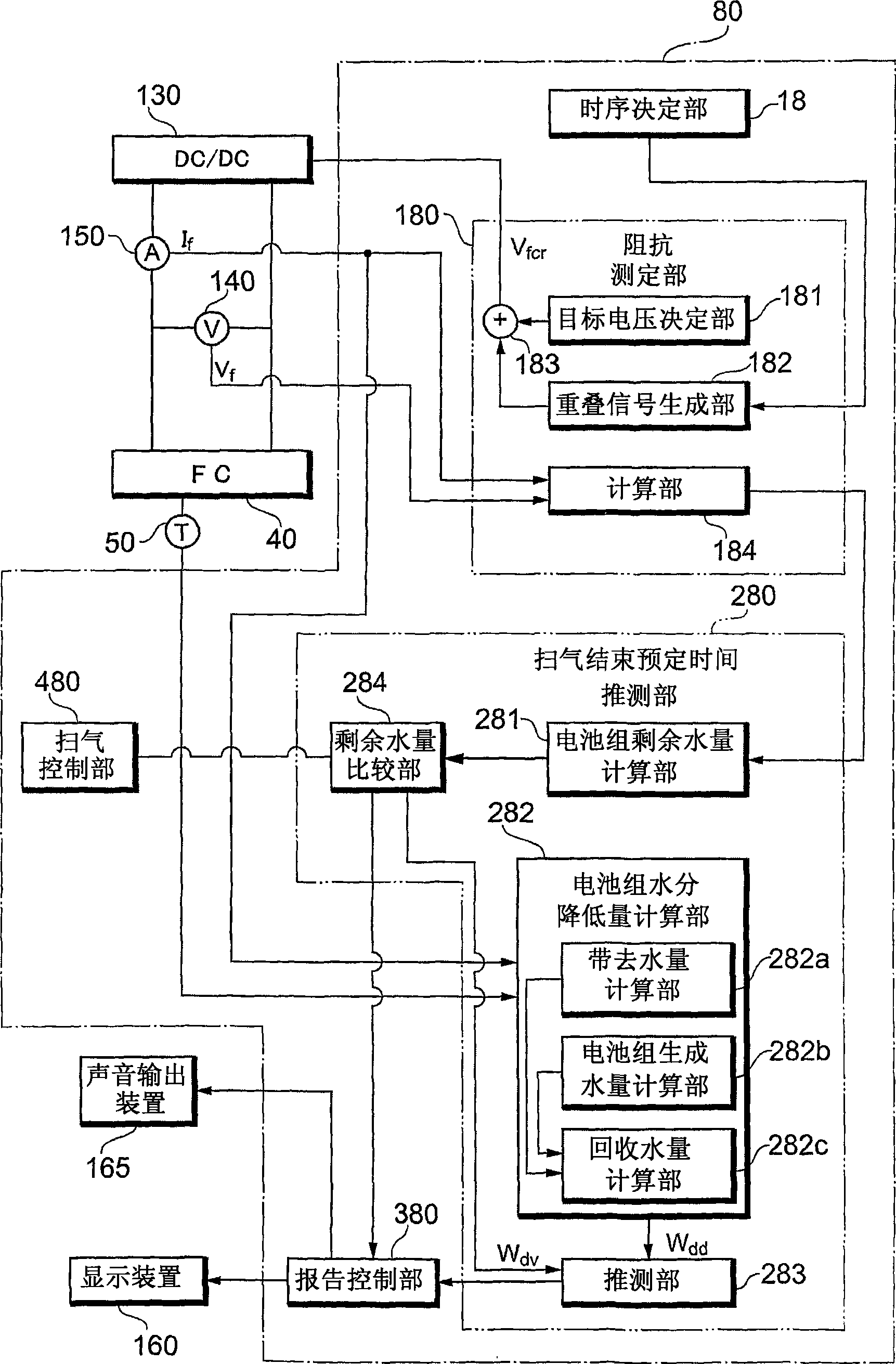

[0030] figure 1 It is a diagram showing the configuration of main parts of the fuel cell system 100 according to the first embodiment. In this embodiment, it is assumed that a fuel cell system mounted on a vehicle such as a fuel cell vehicle (FCHV: Fuel Cell Hybrid Vehicle), an electric vehicle, or a hybrid vehicle is applicable, but it can be applied not only to vehicles but also to various mobile bodies. (such as ships, aircraft, robots, etc.), fixed power supply.

[0031] The fuel cell 40 is a means for generating electric power from supplied reaction gases (fuel gas and oxidizing gas), and various types of fuel cells such as solid polymer type, phosphoric acid type, and molten carbonate type can be used. The fuel cell 40 has a stack structure in which a plurality of unit cells including MEAs and the like are stacked in series. The output voltage (hereinafter referred to as FC voltage) and output current (hereinafter referred to as FC current) of the fuel cell 40 are dete...

no. 2 approach

[0088] In the above-mentioned first embodiment, the case where the control for low temperature countermeasures is performed when the system is terminated is described, but there are also cases where control for low temperature countermeasures such as warm-up processing is required at the time of system startup, for example. Embodiments for realizing the control will be described below. In addition, since the hardware configuration of the fuel cell system according to the second embodiment is the same as that of the above-mentioned first embodiment, illustration and detailed description thereof will be omitted.

[0089] Figure 9 It is a flowchart showing activation processing according to this embodiment.

[0090] If the control unit 80 detects that the ignition switch is turned on, it will grasp the FC temperature T at that moment from the temperature sensor 50 f (step S310→step S320). Furthermore, the control unit 80 controls the preset allowable temperature T c (Tempera...

Deformed example 1

[0096] In the second embodiment, the change of FC temperature is shown, but it is also possible to change according to the FC temperature T f Calculate the amount of change to reach the allowable temperature T c The display device 160 and the voice output device 165 output the predetermined time (time related to the control for low-temperature countermeasures; hereinafter referred to as the Ready ON predetermined time) until now. Here, when displaying the scheduled Ready ON time, the number of seconds until the start of the normal operation may be displayed with numerical markers, or the elapsed time from the scheduled Ready ON time may be displayed with a bar graph. Here, the scheduled Ready ON time can be corrected step by step while calculating in real time, but it does not need to be corrected unless strict accuracy is required (for example, when the scheduled Ready ON time is displayed with a bar graph image, etc.). In addition, it is not necessarily necessary to report ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com