Method for preparing modified ultra-high molecular mass polyethylene micropore filter element

An ultra-high molecular weight, polyethylene technology, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve problems such as incomplete filtration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

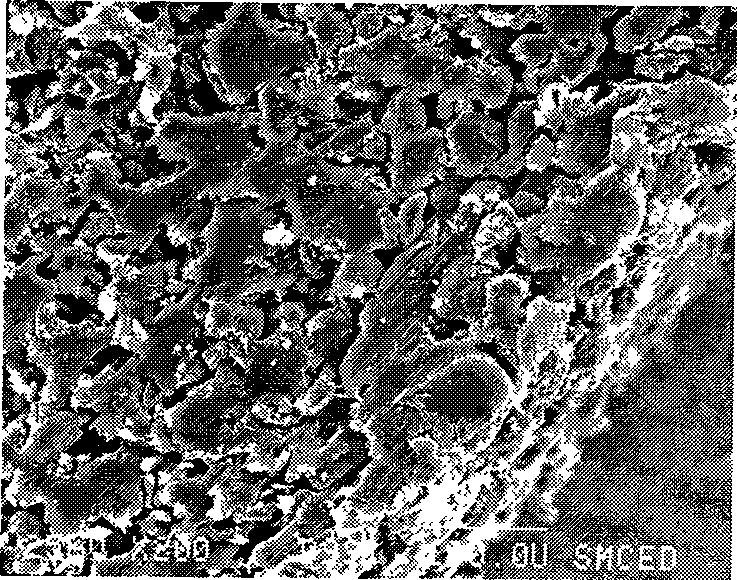

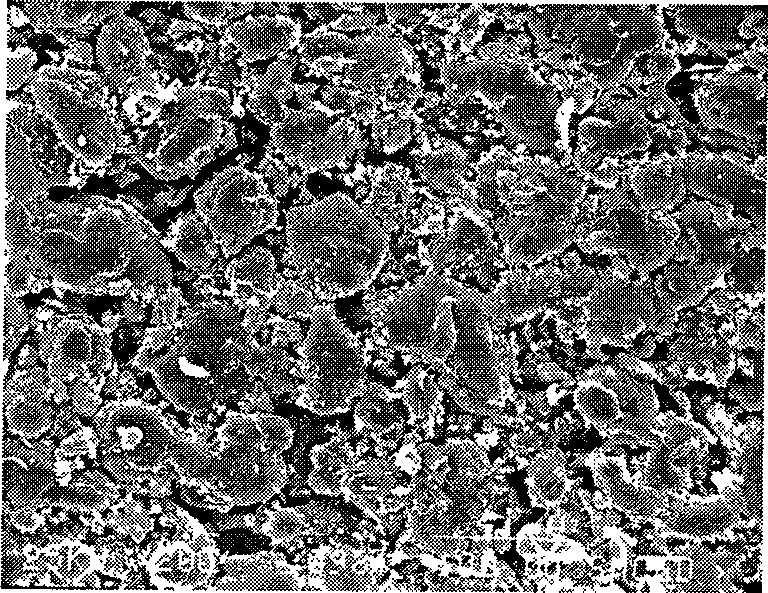

Image

Examples

Embodiment 1

[0034] Embodiment 1, a preparation method of a modified ultra-high molecular weight polyethylene microporous filter element, select ultra-high molecular weight polyethylene, zeolite, and activated carbon with a molecular weight of 3 to 4 million; the mass ratio of polyethylene: modified zeolite: activated carbon is: 60:15:5,

[0035] Production process: Polyethylene passes through a 100-mesh sieve, activated carbon passes through a 100-mesh sieve, and modified zeolite passes through a 100-mesh sieve, batching according to the mass ratio, loading into a mold, and sintering. Sintering temperature: 170-250°C, sintering time: 1-3 hours, step heating method: heat the temperature of the sintering furnace to 130-155°C, put the membrane material with a stainless steel mold into the sintering furnace, and keep it warm for 1-2 hours , and then heat the furnace temperature to 170-250 ° C, and then keep warm for 1-2 hours.

[0036] Modification method of natural zeolite:

[0037] ① Zeol...

Embodiment 2

[0040] Embodiment 2, a preparation method of a modified ultra-high molecular weight polyethylene microporous filter element, select ultra-high molecular weight polyethylene, zeolite, and activated carbon with a molecular weight of 3 to 4 million; the mass ratio of polyethylene: modified zeolite: activated carbon is: 80:5:15,

[0041] Production process: Polyethylene passes through a 150-mesh sieve, activated carbon passes through a 150-mesh sieve, and modified zeolite passes through a 200-mesh sieve, batching according to the mass ratio, loading into a mold, and sintering. Sintering temperature: 170-250°C, sintering time: 1-3 hours, heating method: heat the temperature of the sintering furnace to 130-155°C, put the membrane material with a stainless steel mold into the sintering furnace, keep it warm for 1-2 hours, Then heat the furnace temperature to 170-250°C and keep it warm for 1-2 hours.

Embodiment 3

[0042] Embodiment 3, a preparation method of a modified ultra-high molecular weight polyethylene microporous filter element, select ultra-high molecular weight polyethylene, zeolite, and activated carbon with a molecular weight of 3 to 4 million; polyethylene: modified zeolite: activated carbon The mass ratio is: 70:10:10,

[0043] Production process: Polyethylene passes through a 200-mesh sieve, activated carbon passes through a 200-mesh sieve, and modified zeolite passes through a 200-mesh sieve, batching according to the mass ratio, loading into a mold, and sintering. Sintering temperature: 170-250°C, sintering time: 1-3 hours, heating method: heat the temperature of the sintering furnace to 130-155°C, put the membrane material with a stainless steel mold into the sintering furnace, keep it warm for 1-2 hours, Then heat the furnace temperature to 170-250°C and keep it warm for 1-2 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com