Auxiliary tool changing device of drum type chipper

A tool changing device and chipper technology, which is applied in the manufacture of thin wood chips, wood processing equipment, manufacturing tools, etc., can solve the problems of long replacement of flying knives, high labor intensity of workers, and reduced production efficiency, etc., and achieve labor intensity The effect of reducing, prolonging production time and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

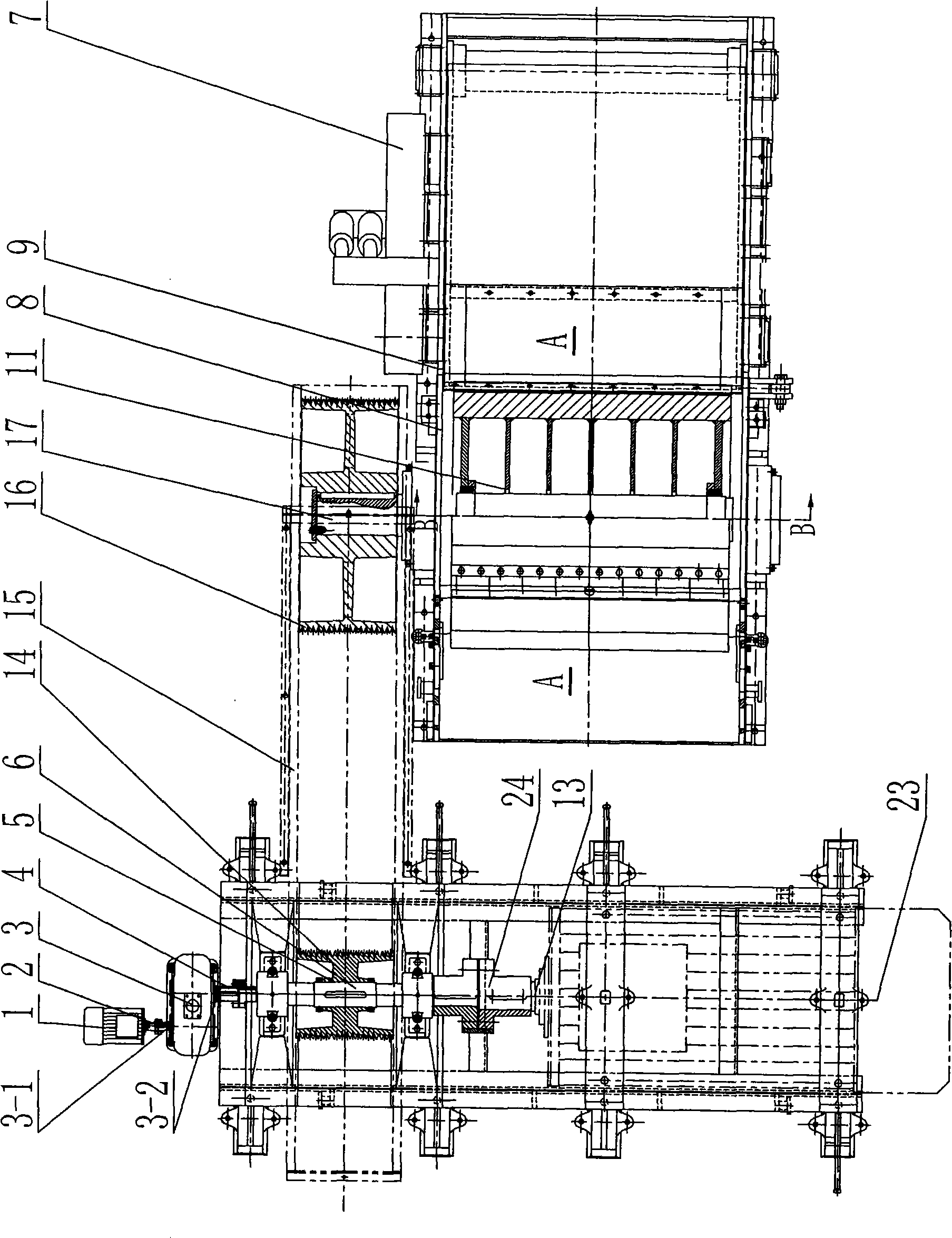

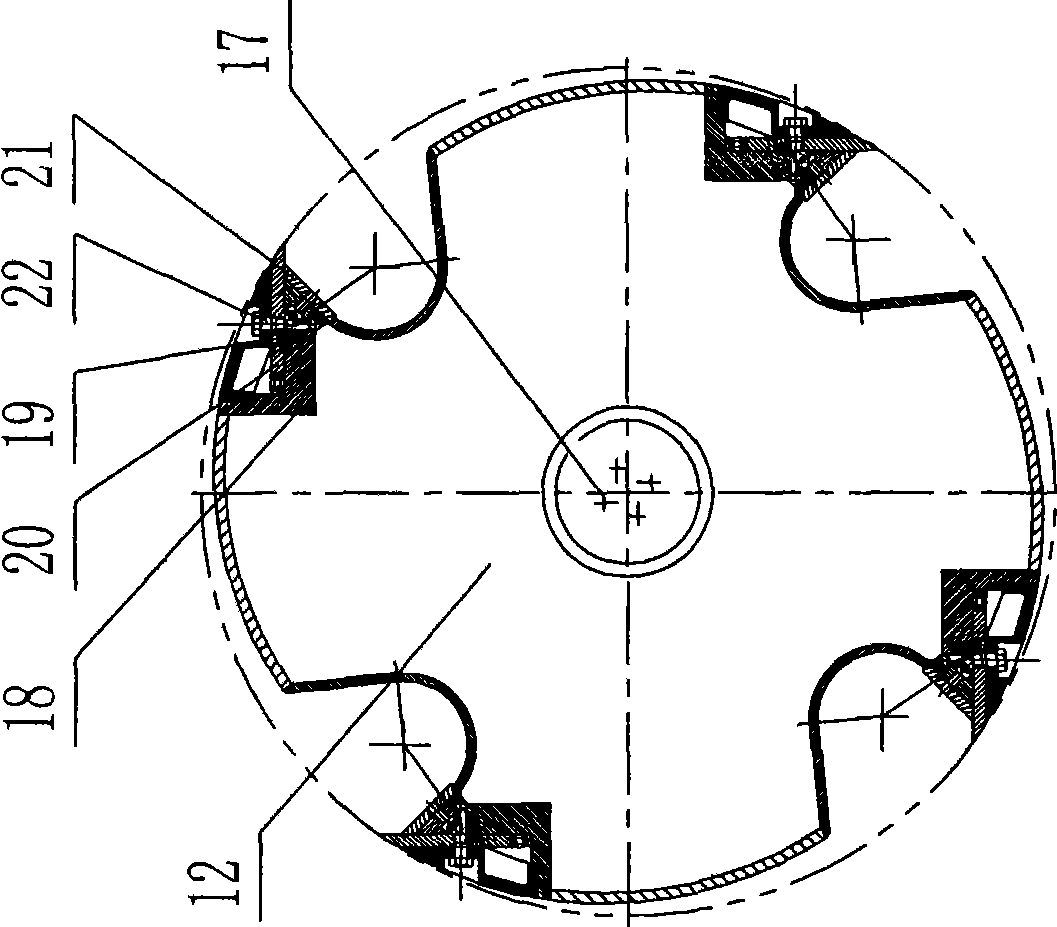

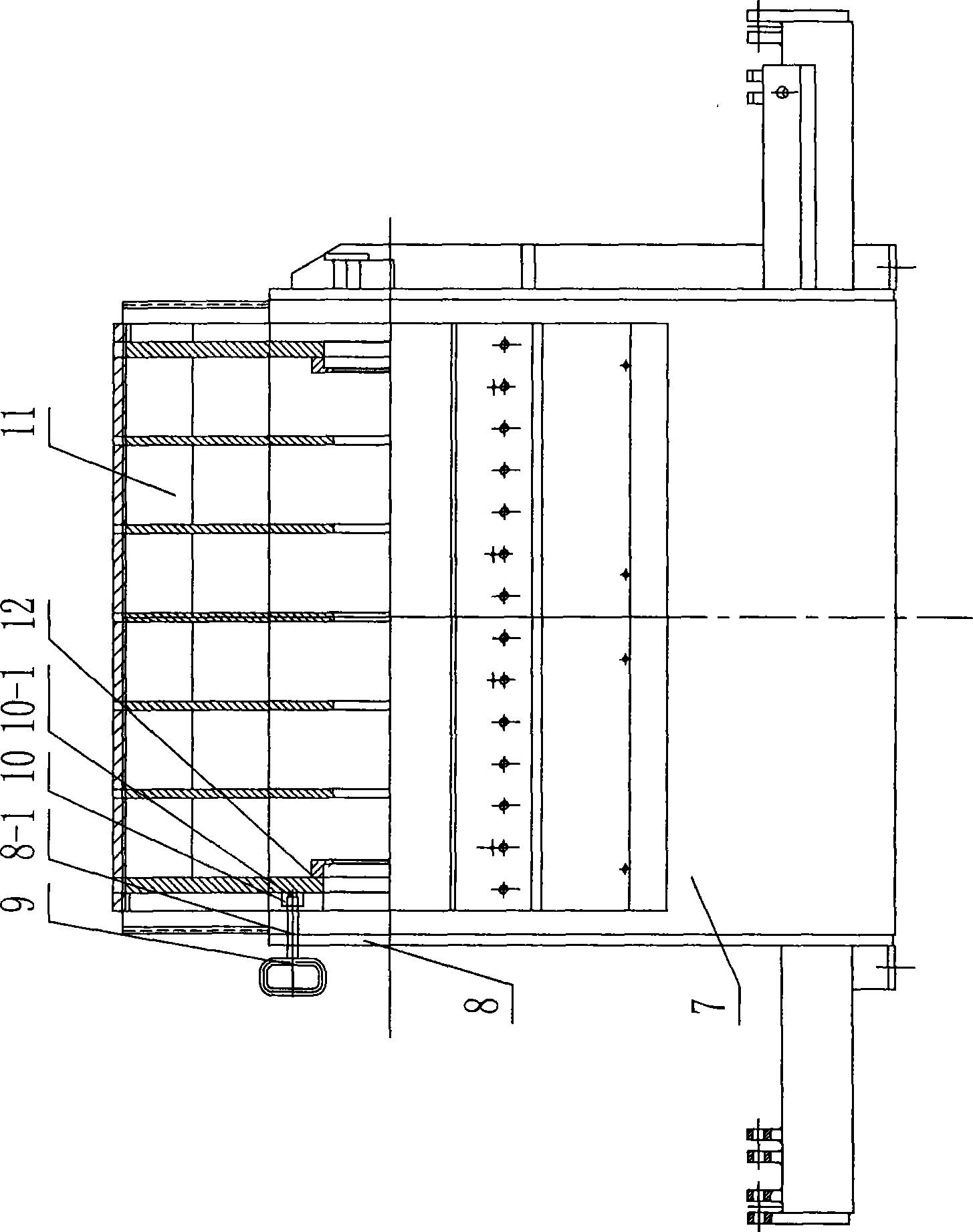

[0016] Such as Figure 1 to Figure 5 As shown, an auxiliary tool change device for a drum chipper includes a pin 9, four positioning blocks 10, a frame hole 8-1, an auxiliary tool change motor 1, a coupling 2, A speed reducer 3, an electromagnetic clutch 4, the positioning block 10 is arranged on the lining plate 12 of the end face of the knife roller 11, a positioning hole 10-1 is opened on each positioning block 10, and the frame hole 8-1 is opened in the drum type On the base side plate 8 of the chipper base 7. The pin 9 is arranged on the frame side plate 8 of the drum chipper frame 7, the reducer 3 has an input shaft 3-1 and an output shaft 3-2, the auxiliary tool change motor 1 is an AC motor, and the auxiliary tool change The motor 1 is connected to the input shaft 3-1 of the reducer 3 through a coupling 2, and the electromagnetic clutch 4 is arranged between the output shaft 3-2 of the reducer 3 and the main shaft 6 of the drum chipper driving device 5. The structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com