360-degree all-revolving shipping pairing rotating paddle propulsion unit

A technology of propulsion device and counter-rotating propeller, which is applied in ship propulsion, propulsion transmission device, transmission device with synchronous propulsion components, etc. Large and other problems, to achieve the effect of light weight, large power range and complete performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

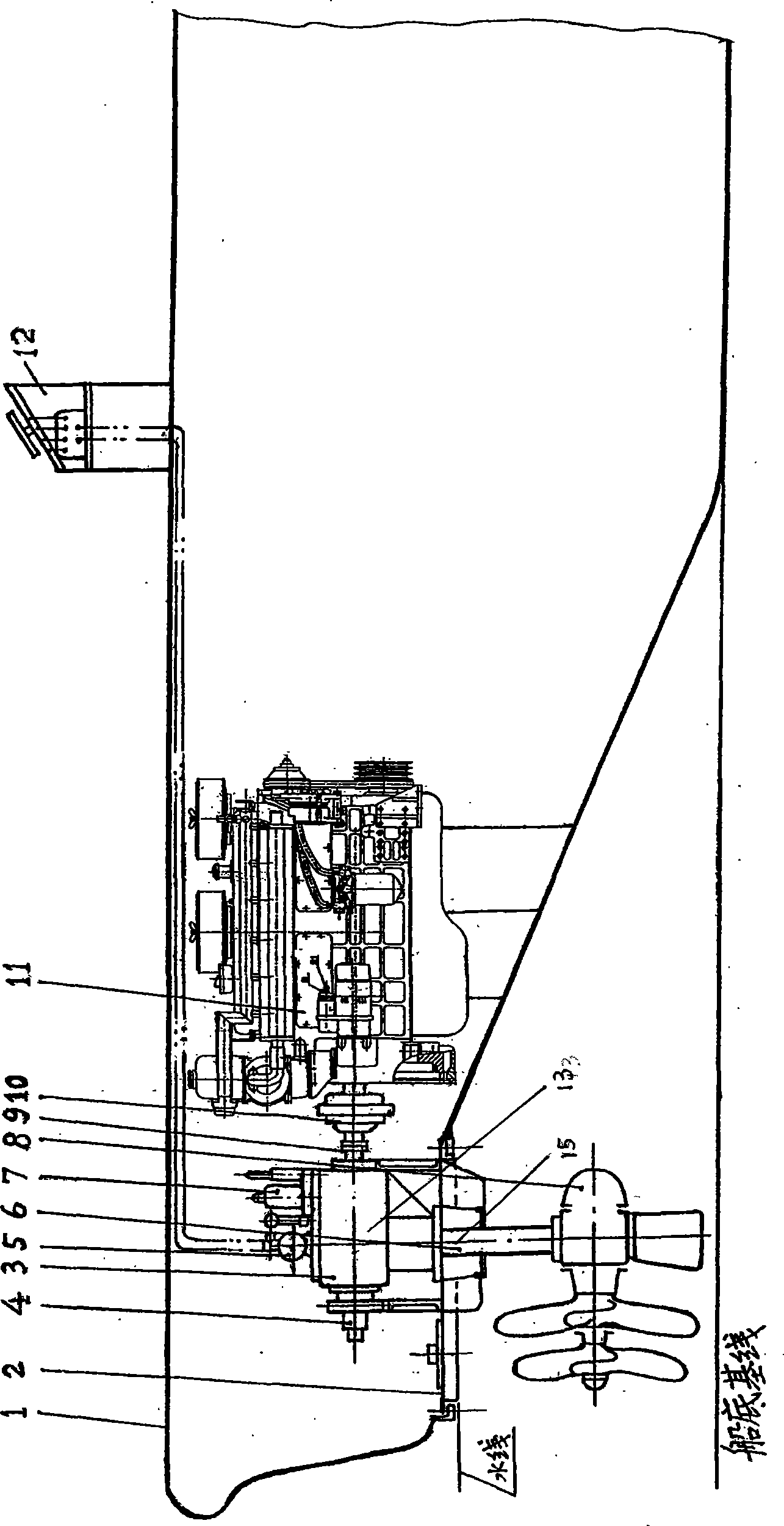

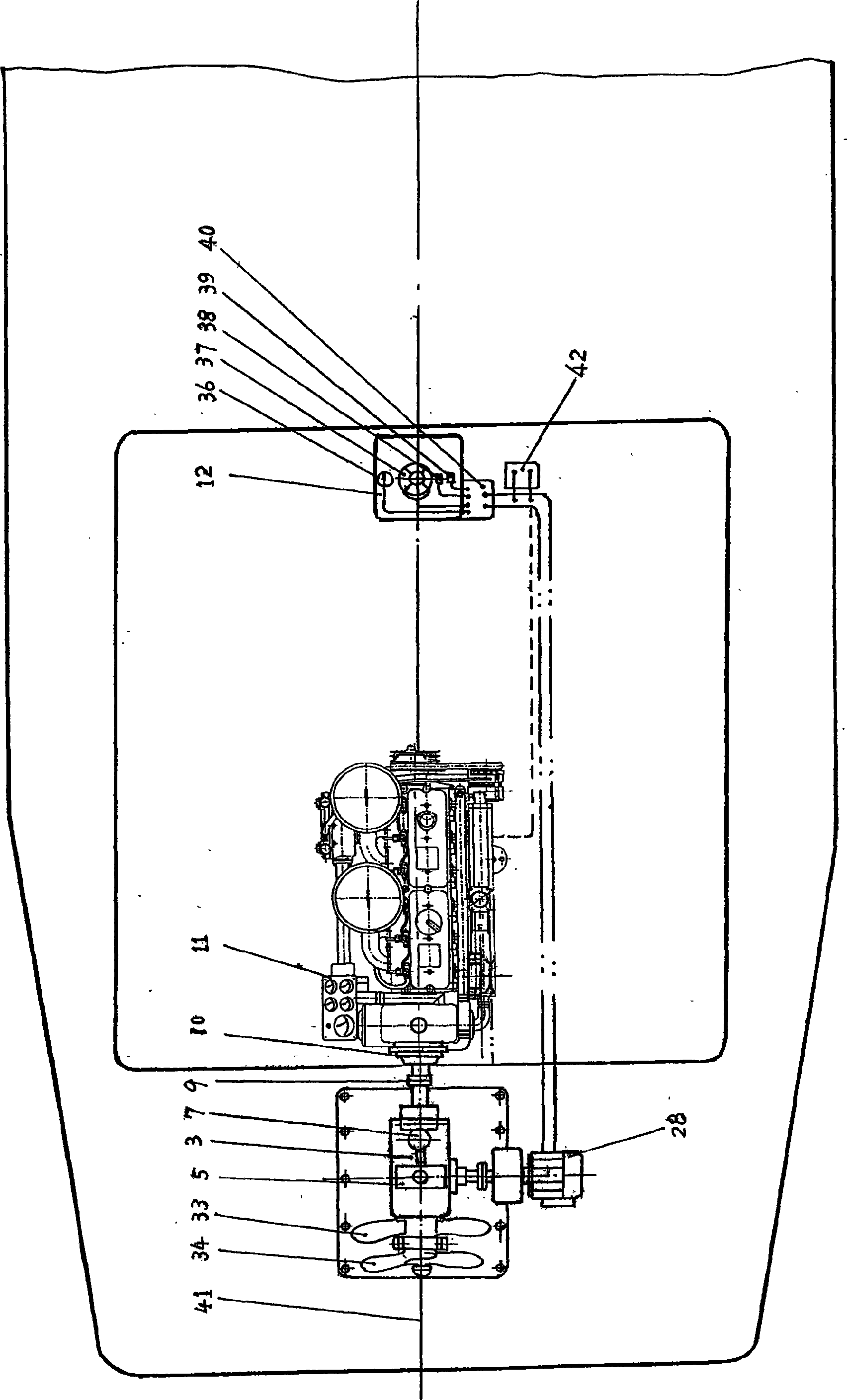

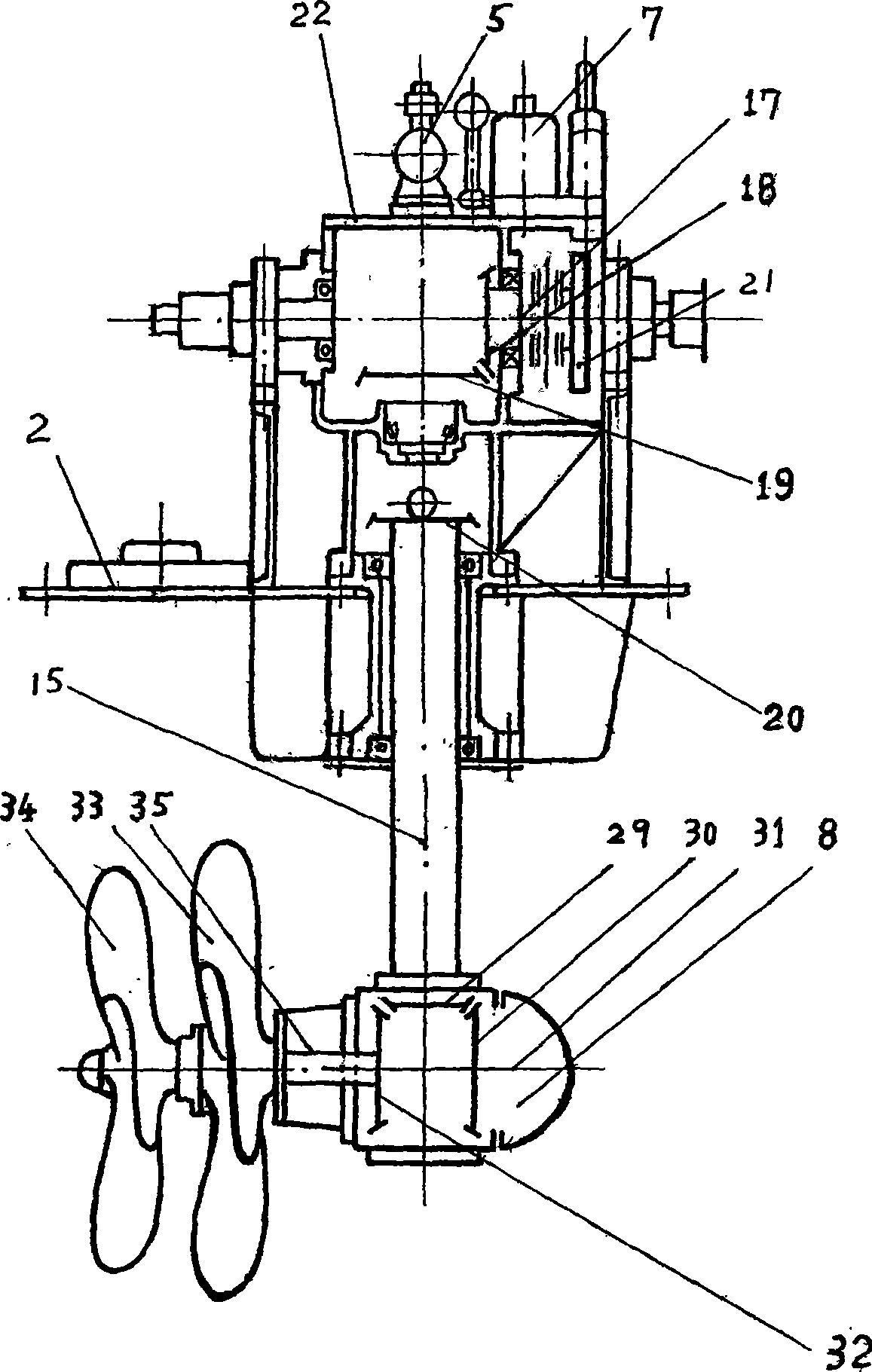

[0028] see figure 1 , the 360° full-turn ship counter-rotating propulsion device of the present invention includes: the rudder rotating body 6 fixed on the stern of the ship, the derrick type sealing cover bracket 2 that protects the rudder rotating body fixed on the fixed sleeve and connected with the hull , drive the first transmission chain of the intermediate transmission shaft 15 in the paddle rudder revolving body, drive the second transmission chain of the revolving part in the paddle rudder revolving body, and manipulate the drive mechanism 12 and the parts connected with the prime mover.

[0029] see figure 1 with 3 , when the prime mover is a diesel engine, the upper box of the propeller rudder rotating body is composed of the upper casing 3 and the lower casing 13 in a Huff type, and is fixed under the stern deck 1; the upper box includes a rotatable Its axis is perpendicular to the intermediate transmission shaft 15 and one end stretches out the rotating shaft 17...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com