Fish residual processing system

A treatment device and collection system technology, applied in water/sewage treatment, bio-organic part treatment, water/sludge/sewage treatment, etc., can solve problems such as troublesome maintenance, short life, and insufficient filtering effect, and achieve fertile soil , the effect of improving the soil

Inactive Publication Date: 2010-12-01

韶关市力冉农业科技有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

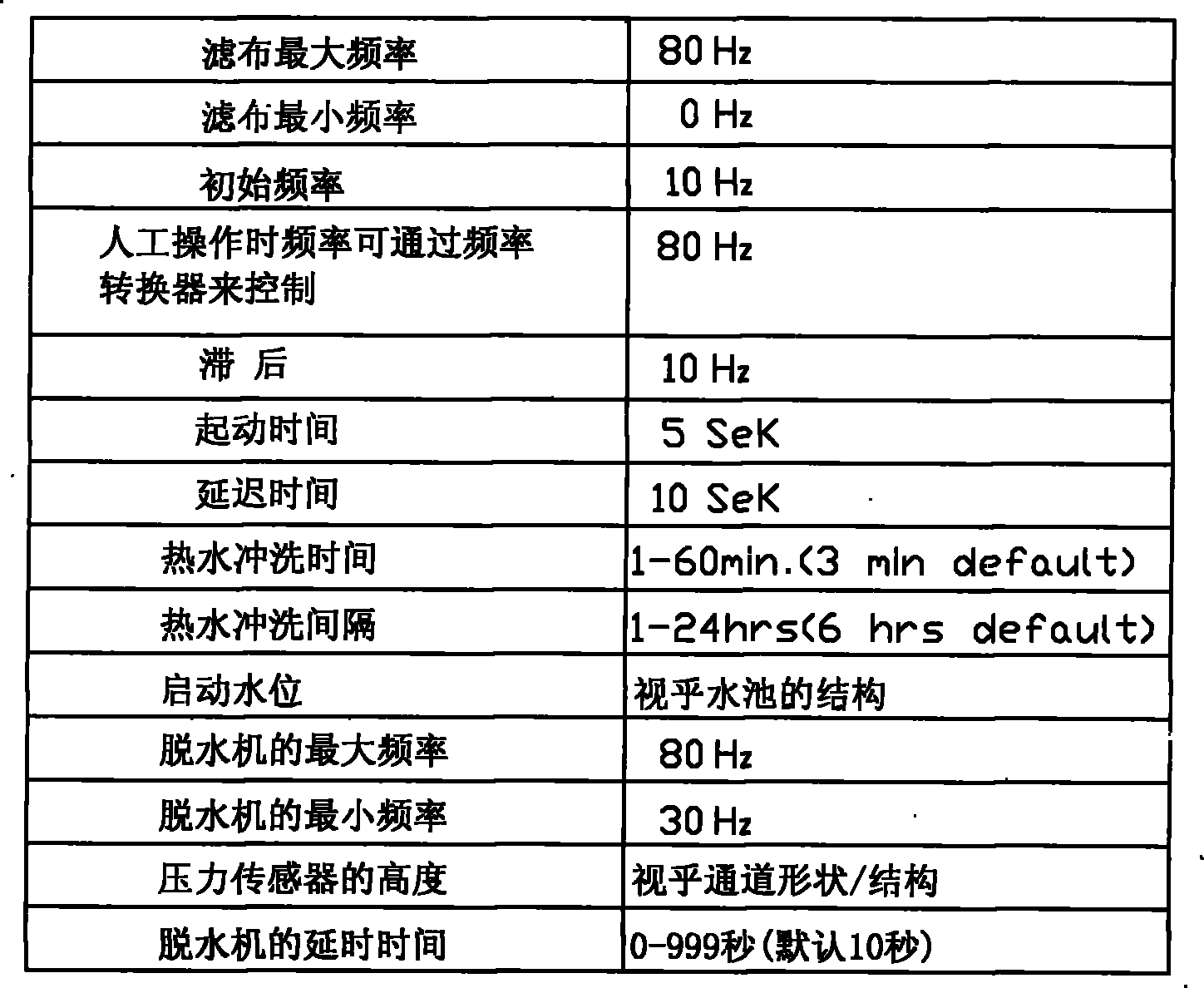

Some domestic enterprises use the traditional sedimentation method or the drum-type mechanical filtration method to filter relatively large particles of fish residue in the water. The filtration effect of these two methods is not thorough enough, and the maintenance is troublesome and the service life is short.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

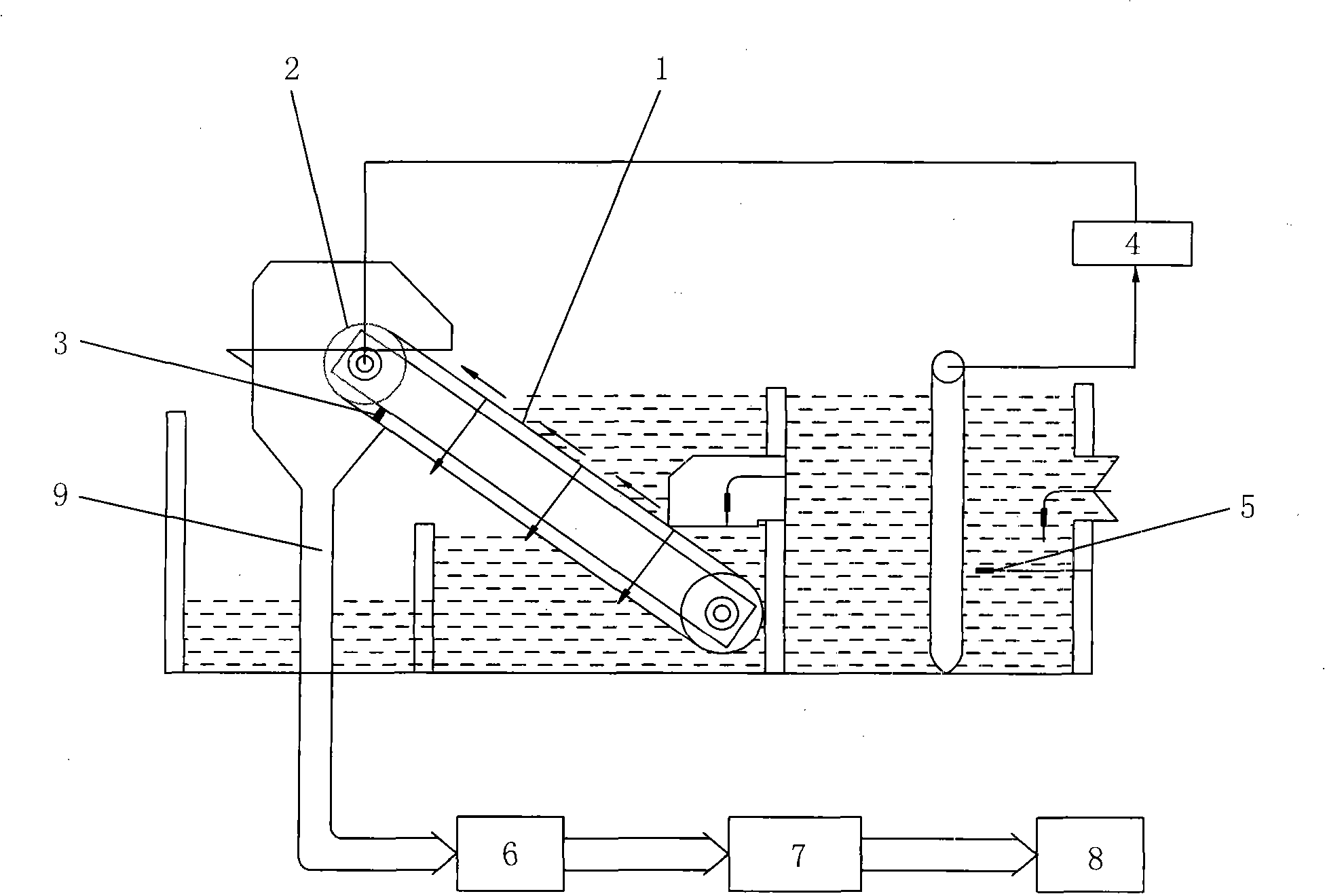

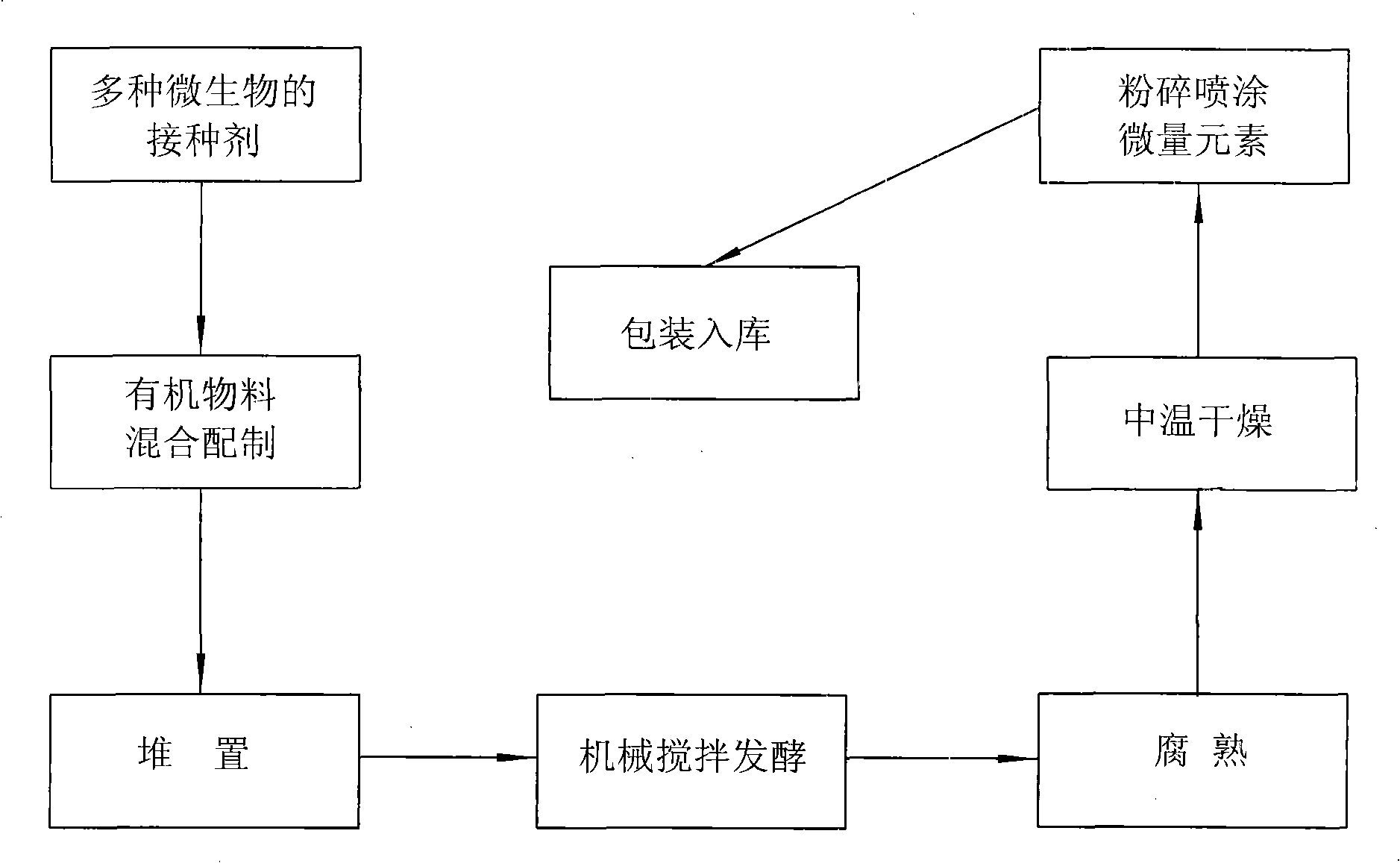

The invention relates to a fish residue treatment system, which mainly comprises a fish residue collecting system and a fish residue processing system, wherein the fish residue collecting system is mainly a mechanical filtering system; the mechanical filtering system adopts a rotary banded filter to perform physical backwashing filtration to aquaculture water; and the fish residue processing system mainly comprises a mixing tank, a fermentation tank and a drying device. The treatment system adopts the rotary banded filter and a backwashing device to effectively treat the water, can efficiently collect fish residue produced in aquaculture, and enables aquaculture pools to operate all the year around without stopping production for to clear filth. The fish residue processing system can be utilized to change fish residue into organic fertilizer with economic benefit. The produced organic fertilizer is thorough in fermentation, cannot be fermented again after application, and can improve soil, rejuvenate soil and fertilize soil. The treatment system realizes the zero emission of aquaculture waste, and ensures that aquaculture enterprises can increase income while saving energy and reducing consumption.

Description

Fish processing system 【Technical field】 The invention belongs to the technical field of waste treatment, and relates to a fish-crack treatment system in aquaculture. 【Background technique】 In traditional aquaculture, fish residues are often treated by clearing ponds. This method requires all aquatic products to come out of the ponds, dig out excess silt, and let the bottom of the ponds freeze and sun-bath for about a week. This method is not only very troublesome and consumes a lot of manpower and material resources, but also takes a very long time to clear the pond once. It is necessary to stop production and clean the fish pond every year, which cannot achieve efficient breeding. After the fish residue is collected, it is often returned to the field after fermentation, which is easily affected by the season and the user's wishes, and is also restricted by the stability of the land absorption. Moreover, it is easy to leak and leak during the process of dispersing and tra...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C05F17/00C02F1/00

CPCY02P20/10Y02W30/40

Inventor 王敏懿

Owner 韶关市力冉农业科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com