Glass fibre reinforced plastic and leisure seat made thereof

A glass fiber reinforced plastic and raw material technology, applied in the field of leisure seats, can solve the problems of poor aging resistance, heavy product weight, easy cracking, etc., and achieve the effects of smooth two sides, low production cost and short production cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

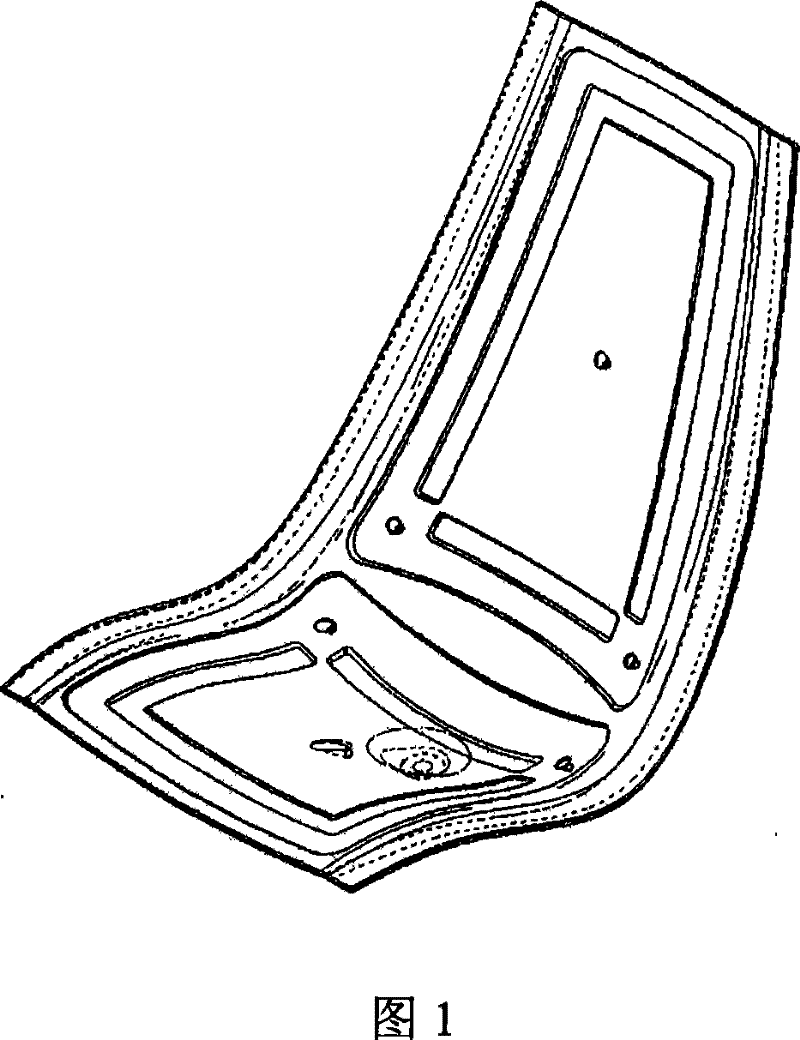

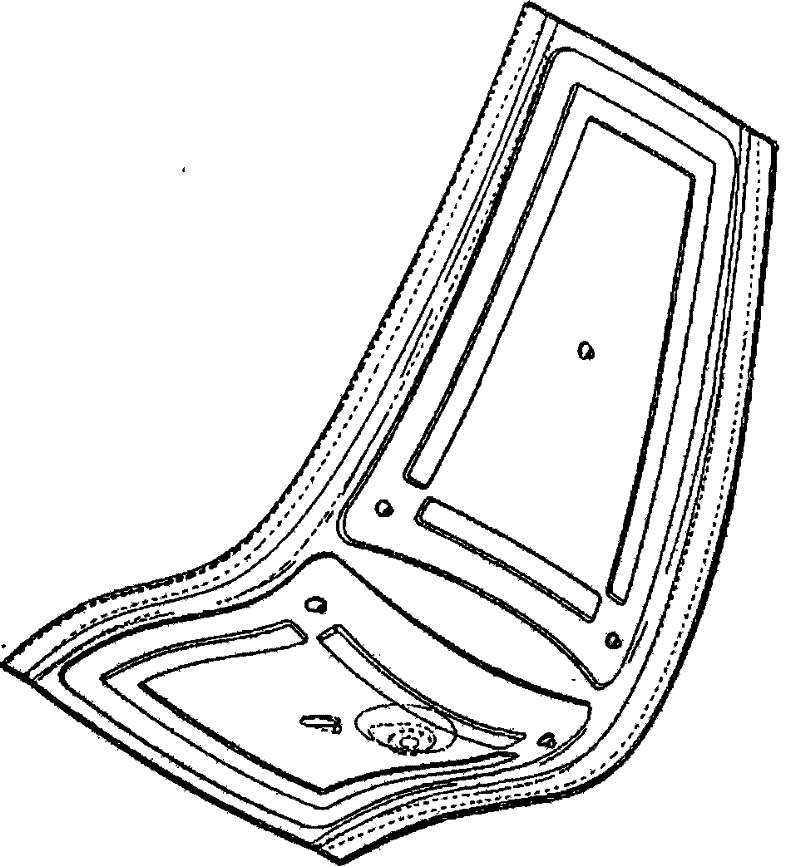

[0033] A leisure seat such as figure 1 As shown, it is made of a fiberglass material. Taking the manufacture of 12kg (net weight) FRP as an example, raw materials of the following qualities are required.

[0034] Ingredients:

[0035] Gel coat 8373-w-9910 1.2kg

[0036] FL-RTM resin 7.27kg

[0037] 1450g / m 2 Closed mold felt 2.65kg

[0038] 300g / m 2 Chopped strand mat 0.5kg.

[0039] FL-RTM resin is RTM resin produced by Jiangsu Fuling Chemical Co., Ltd.

[0040] Accessories:

[0041] Polyurethane foam material A 0.5kg

[0042] Polyurethane foam material B 0.5kg

[0043] Calcium carbonate filler 60 mesh weight 1.65kg

[0044] Resin curing agent MEKP (methyl ethyl ketone peroxide) 0.21kg

[0045] Resin accelerator cobalt isooctanoate 0.09kg

[0046] White primer PC2000 (including curing agent) 1.4kg

[0047] White topcoat PC2000RAL9010 (including curing agent) 0.85kg

[0048] Paint Thinner 1.31kg.

[0049] The white primer PC2000 and the white top coat PC2000RAL...

Embodiment 2

[0064] A leisure seat such as figure 1 As shown, it is made of a fiberglass material. Taking the manufacture of 14kg of this kind of FRP as an example, the following quality raw materials are required.

[0065] Ingredients:

[0066] Gel coat 8373-w-9910 1.2kg

[0067] FL-RTM resin (Jiangsu Fuling) 7.34kg

[0068] FL-191 resin (Jiangsu Fuling) seat for a backing plate 1.34kg

[0069] 1450g / m 2 Closed mold felt 2kg

[0070] 300g / m 2 Chopped strand mat 0.6kg

[0071] Accessories:

[0072] Polyurethane foam material A 0.5kg

[0073] Polyurethane foam material B 0.5kg

[0074] Calcium carbonate filler 60 mesh weight 1.82kg

[0075] Resin curing agent MEKP methyl ethyl ketone peroxide 0.24kg

[0076] Resin accelerator cobalt isooctanoate 0.3kg

[0077] White primer PC2000 (including curing agent) 1.4kg

[0078] White topcoat PC2000RAL9010 (including curing agent) 1.1kg

[0079] Paint Thinner 2.62kg.

[0080] The method step of making this leisure seat is the same as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com