On-site detecting instrument for foundation bearing capacity and filling compactness

A technology of foundation bearing capacity and compactness, which is applied in the field of foundation soil survey, foundation structure engineering, foundation structure test, etc. major problems, to achieve considerable social benefits, save manpower and material resources, and avoid visual errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

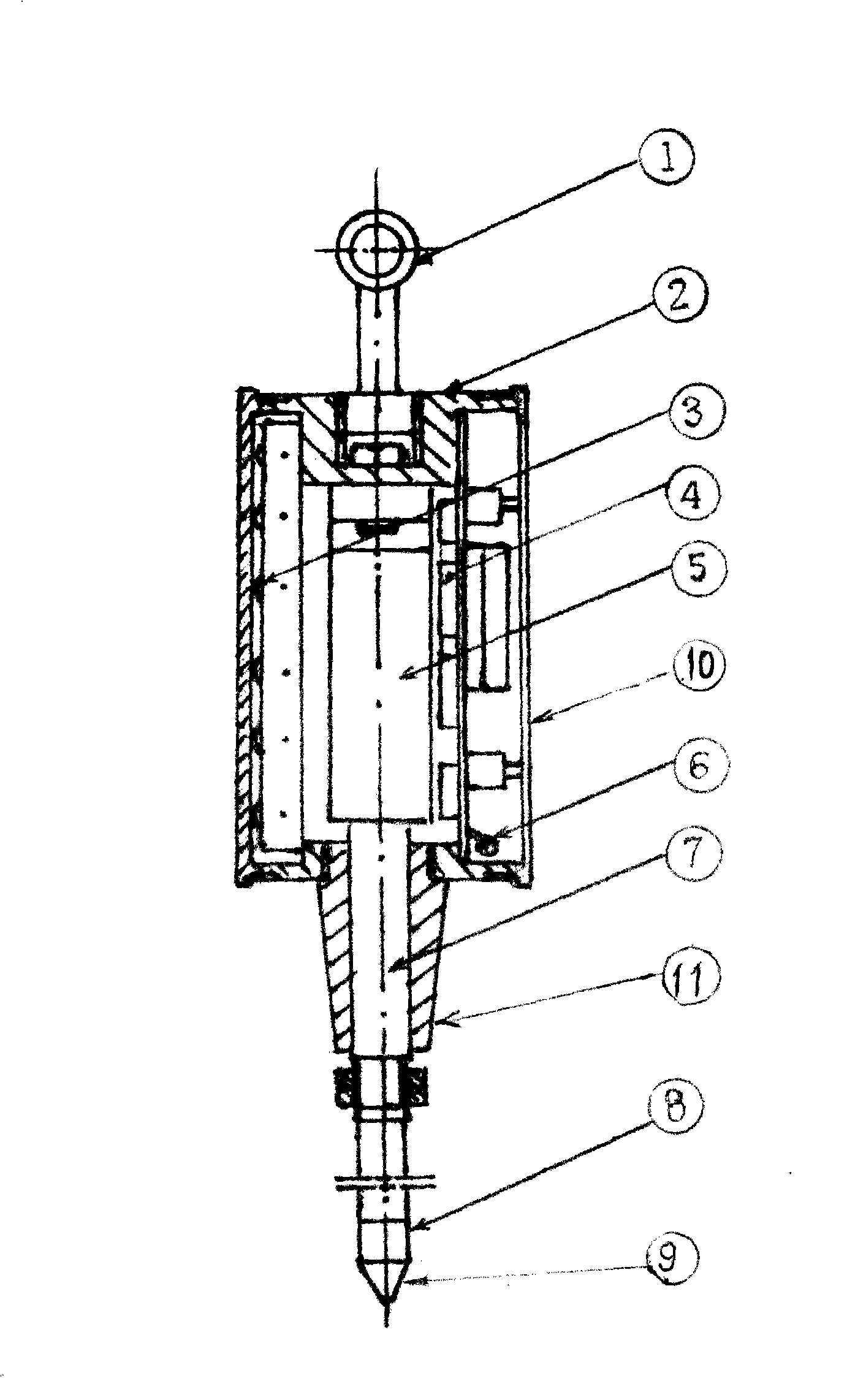

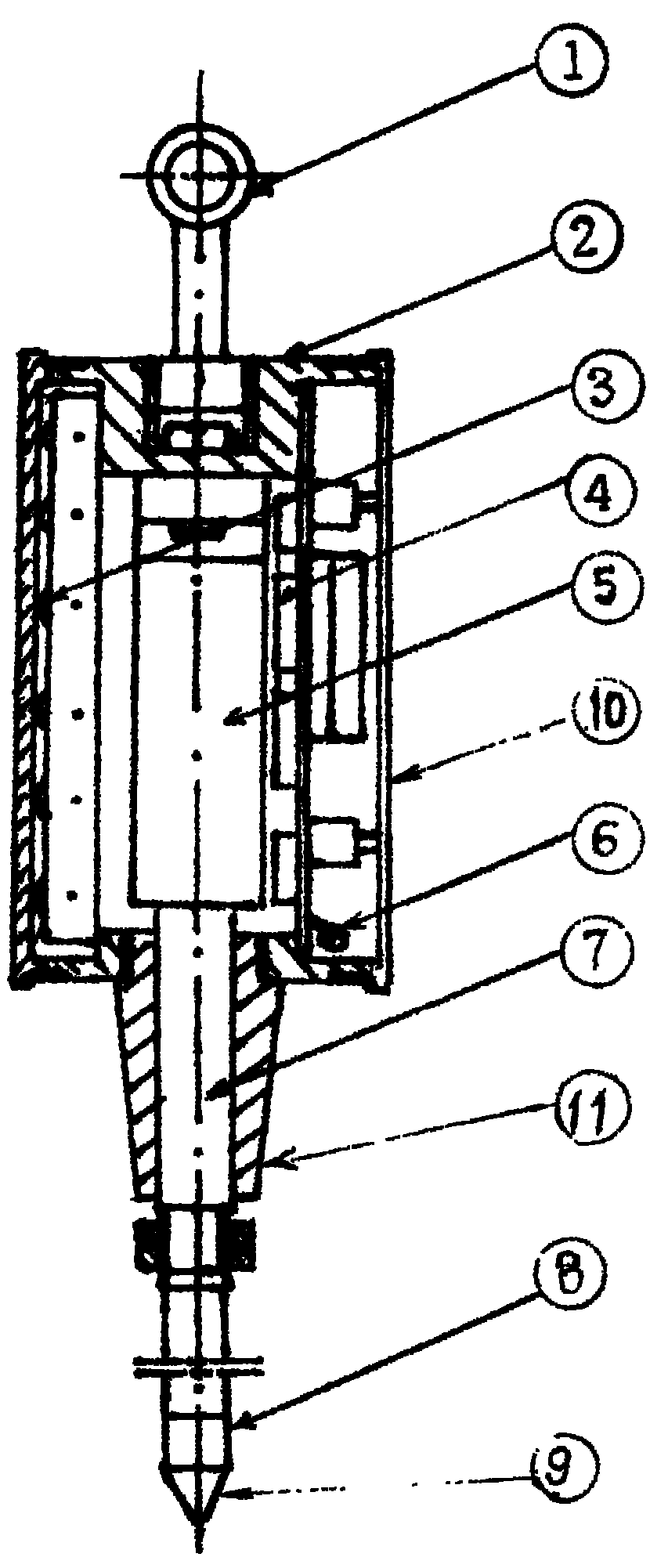

[0010] Fig. 1 is an embodiment of this design scheme: a special casing 2 systematically combines the load sensor 5-mechanical transmission system (transmission shaft 7, probe rod 8, probe 9)-data acquisition processor 4 , its features: the top of the casing 2 is provided with a T-shaped beam 1, the center of the inner cavity of the casing 2 is fixed with a load sensor 5, the bottom of the casing 2 is equipped with a displacement guide sleeve 11, and the casing 2 is equipped with a data acquisition device. The processor 4, the power supply box 3, and the casing 2 are equipped with a control display panel 10 and a communication interface 6. The load sensor 5 is connected with the transmission shaft 7, and then connected with the probe rod 8 and the probe 9 in turn.

[0011] The penetrating rod 8 in Fig. 1 is designed as a single-section or multi-section structure according to the detection requirements, and the sections are connected by threads, keyways, and nails. The surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com