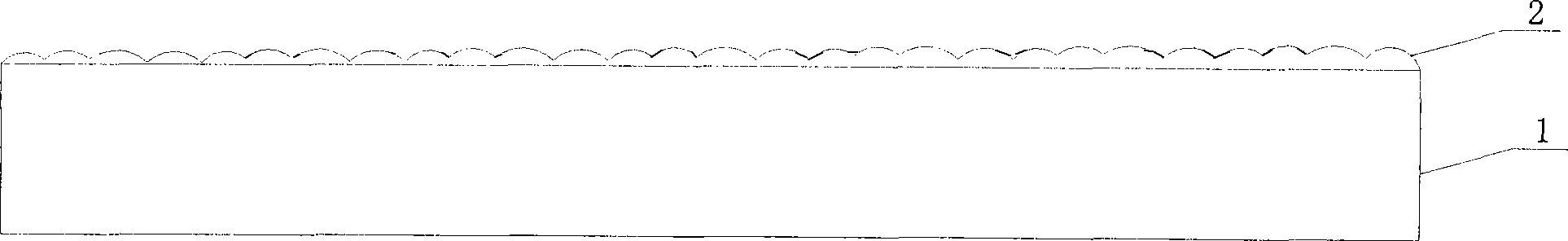

Fabrication technique of bi-component antiskid polyurea terrace paint surface

A floor coating and manufacturing technology, applied to polyurea/polyurethane coatings, coatings, floors, etc., to achieve fast construction speed, comfortable feet, and good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below through specific embodiments in conjunction with the accompanying drawings.

[0026] The polyurea that this embodiment uses is the two-component polyurea of following formula:

[0027] A component: N220 14.5 parts by weight,

[0028] N210 46.2 parts by weight,

[0029] LMD1 35.3 parts by weight,

[0030] DOP 1.0 parts by weight,

[0031] 3.0 parts by weight of silicone oil;

[0032] B component: D2000 5.2 parts by weight,

[0033] T5000 14.2 parts by weight,

[0034] DETDA 67.6 parts by weight,

[0035] DMTDA 3 parts by weight,

[0036] DOP 4 parts by weight,

[0037] 5 parts by weight of carbon black,

[0038] 1 part by weight of silicone oil.

[0039] The weight ratio of A component and B component is 1:1.

[0040] The spray gun is GX-7 type spray gun, the technical parameters are as follows: maximum output: 18kg / min, minimum output:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com