Binding strength detecting instrument for waterproof layer of bridge

A technology of bond strength and waterproof layer, applied in the field of bond strength tester for bridge waterproof layer, can solve the problems of inability to guarantee free water infiltration, large corrosion effect of steel bars, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

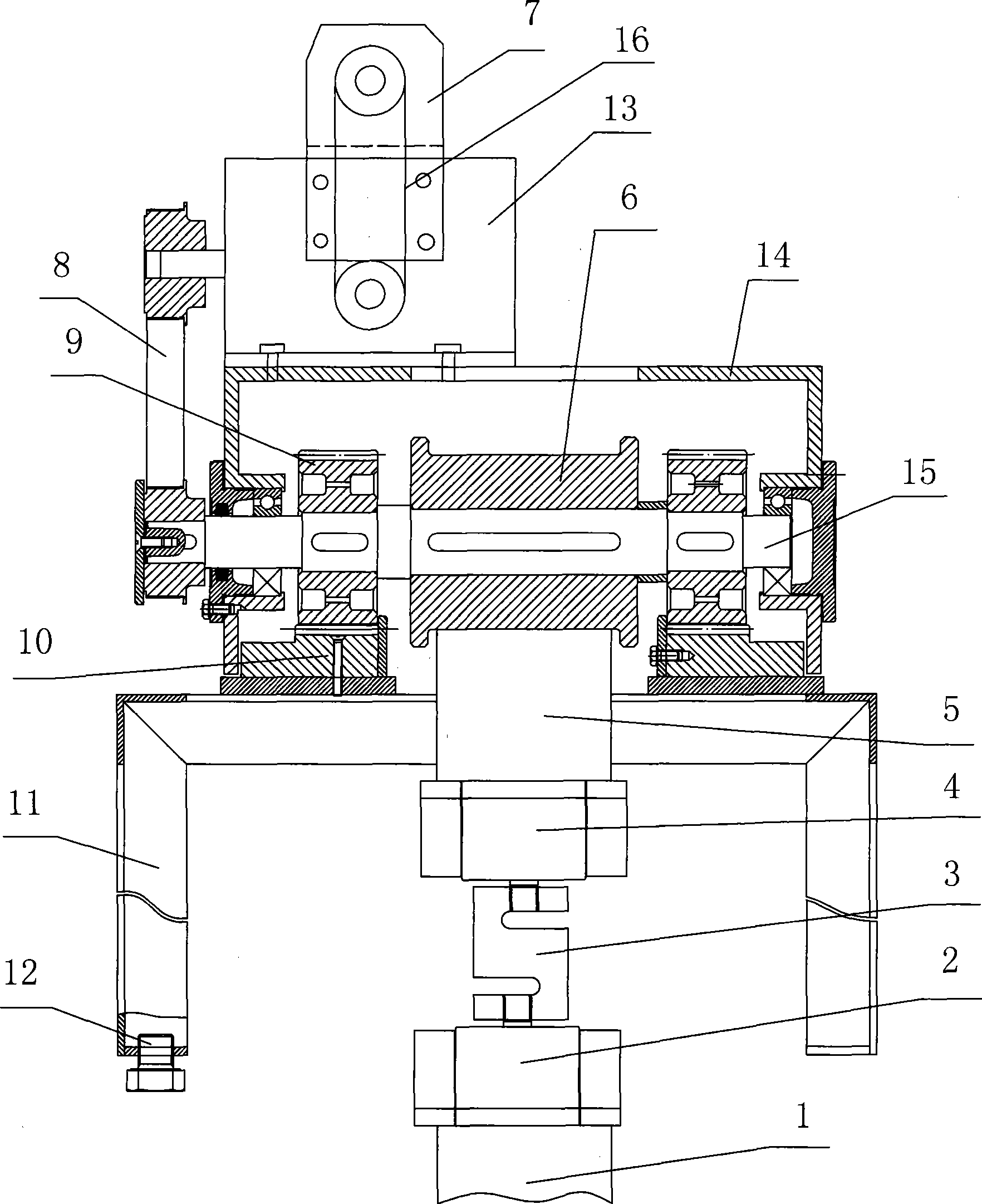

[0025] Such as figure 1 As shown, the present invention includes a frame 11, a drive motor 7, a mobile box 14 that is arranged on the top of the frame 11 and can move forward and backward, and is driven by the drive motor 7 through a transmission system to rotate and is set inside the mobile box 14. The transmission shaft 15, the transmission gear 9 and the roller 6 sleeved on the transmission shaft 15, the rack 10 that meshes with the transmission gear 9 and drives the moving box 14 to move forward, and the tear that acts on the waterproof layer 1 to be detected The tension sensor 3 for real-time detection of force, the roller 6 is provided with a tearing belt driven upward by it, the tearing belt is connected with the waterproof layer to be detected through the tearing clip, and the rack 10 is fixed on the frame 11, the roller 6 is coaxial with the transmission gear 9 and the pitch diameters are equal. The roller 6 is provided with a tearing belt driven upward by it, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com