Multi-module data transmission communication system

A data transmission and communication system technology, applied in the direction of comprehensive factory control, presses, comprehensive factory control, etc., can solve the problems of low system control precision, inadaptability to production requirements, inconvenient on-site maintenance, etc., to simplify control programming and shorten debugging Cycle time, the effect of improving production efficiency and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to further understand the invention content, characteristics and effects of the present invention, the following embodiments are listed hereby, and the multi-module data transmission communication system of the present invention is described in detail with reference to the accompanying drawings as follows:

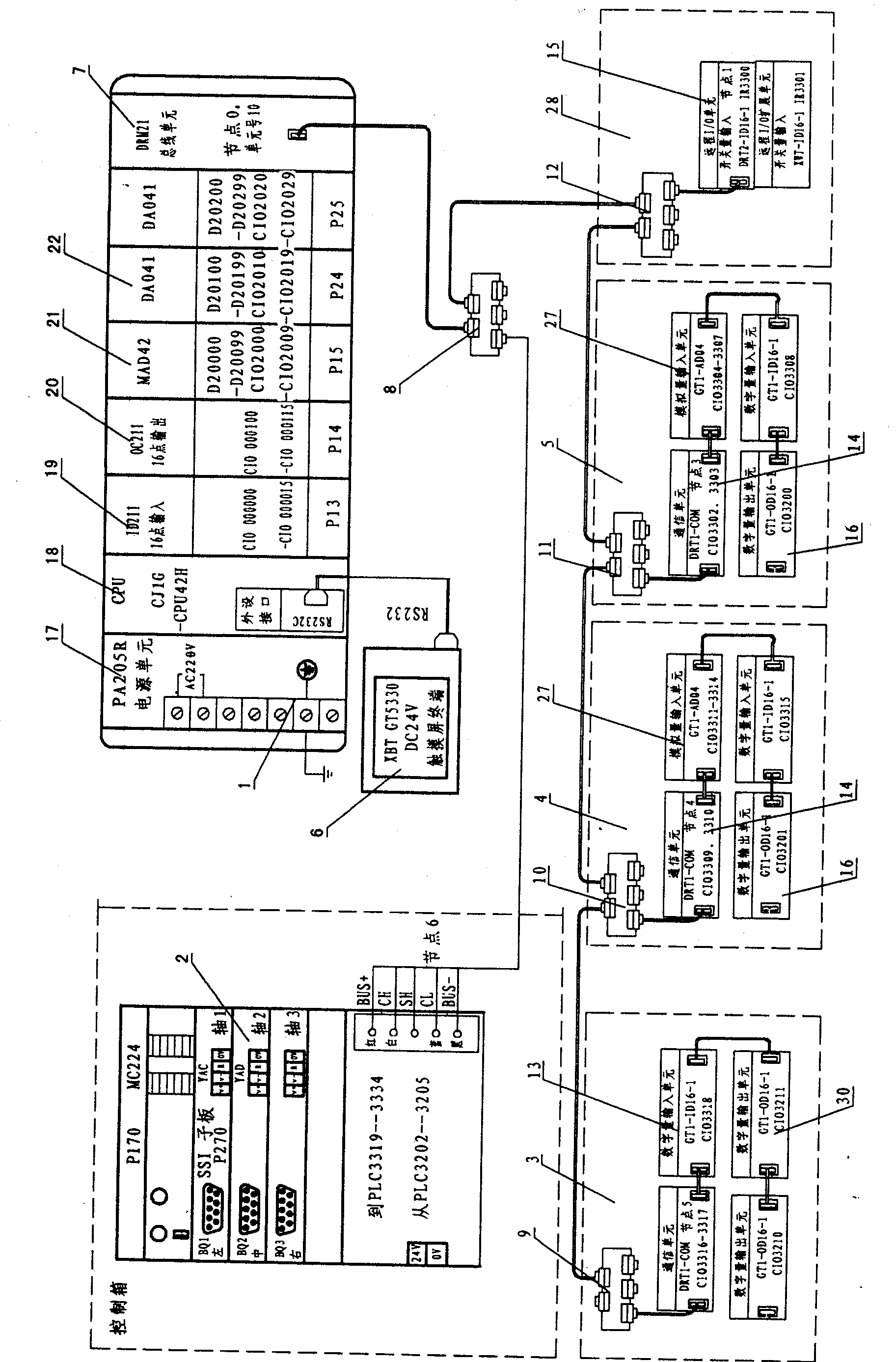

[0016] The present invention uses the DeviceNet industrial field bus as the network layer, between the PLC programmable controller and the TRIO controller and between the slave stations as the PLC programmable controller sub-modules all adopt the DeviceNet industrial bus communication, the whole control The system is formed by the DeviceNet industrial bus. The input devices connected to the DeviceNet network include buttons, emergency stop switches, proximity switches, photoelectric switches, travel switches, sensors, etc., and the output devices include indicator lights, control valves, frequency converters, etc.

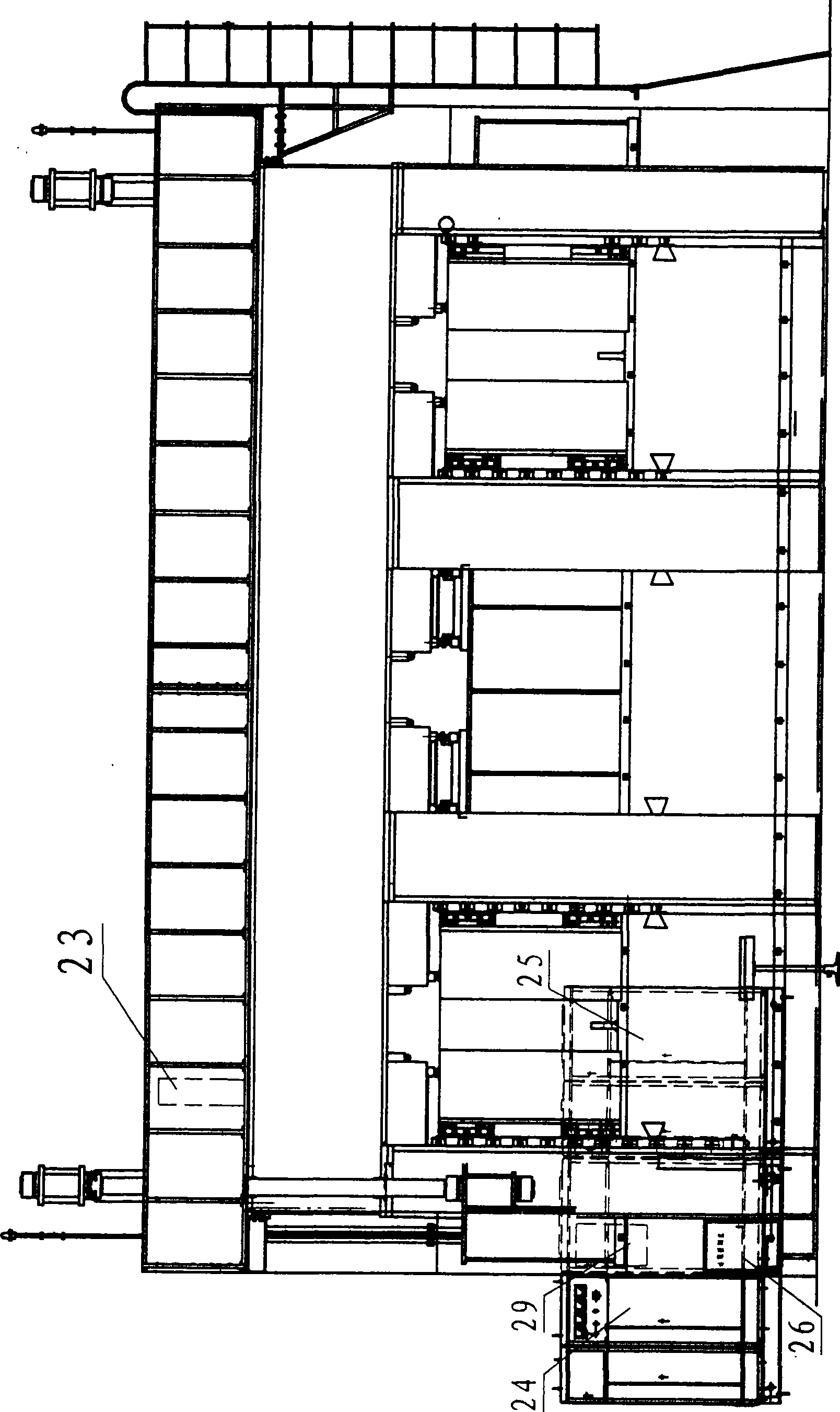

[0017] like figure 1 As shown, the multi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com