Process for generating low repeat frequency ultra-short laser pulse

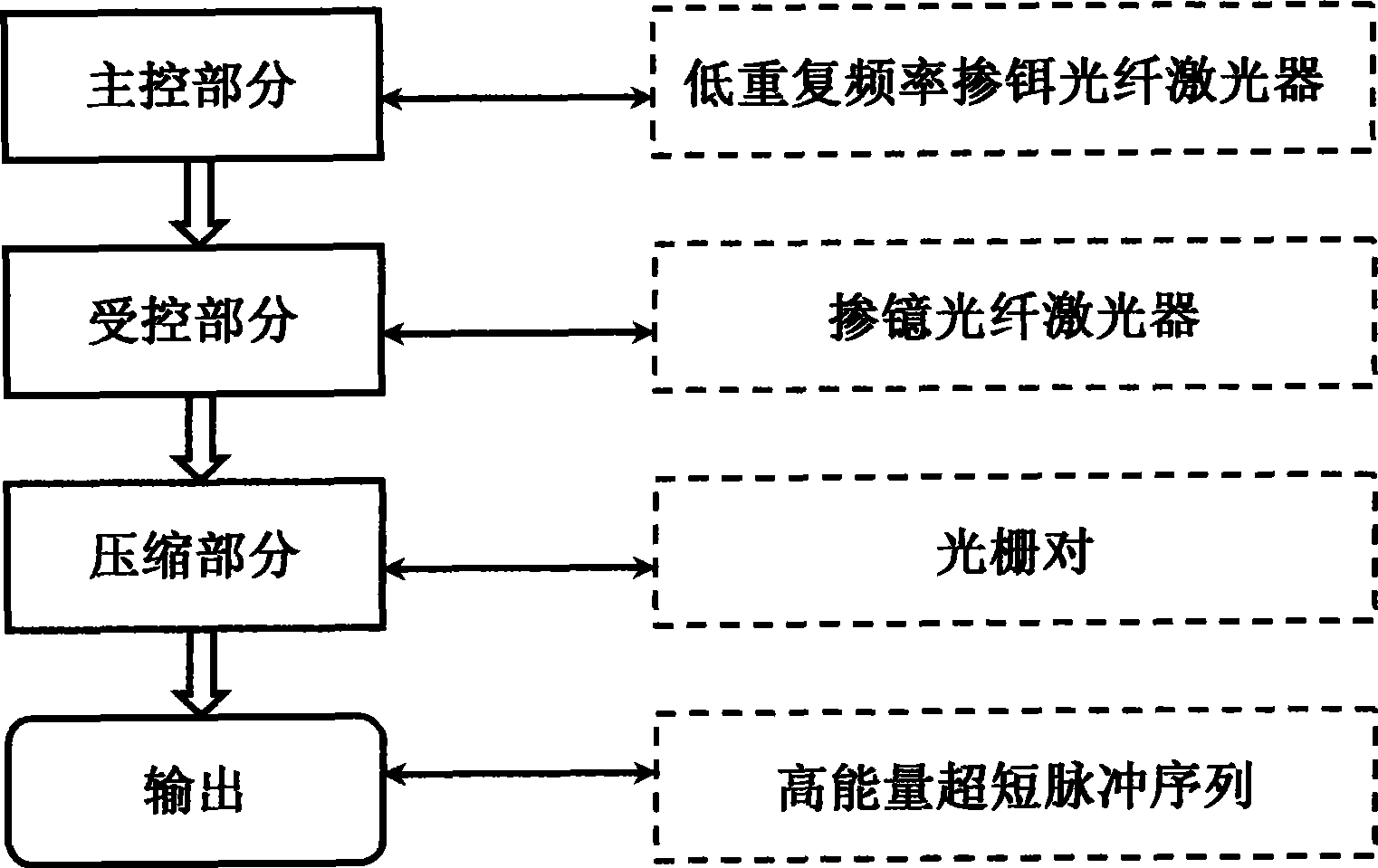

A repetition rate, ultra-short laser technology, which is applied in the direction of lasers, laser components, and the structure/shape of active media, can solve energy waste, reduce the repetition rate of fiber lasers, lose lightness of fiber lasers, etc. Problems, to achieve good practicability , simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

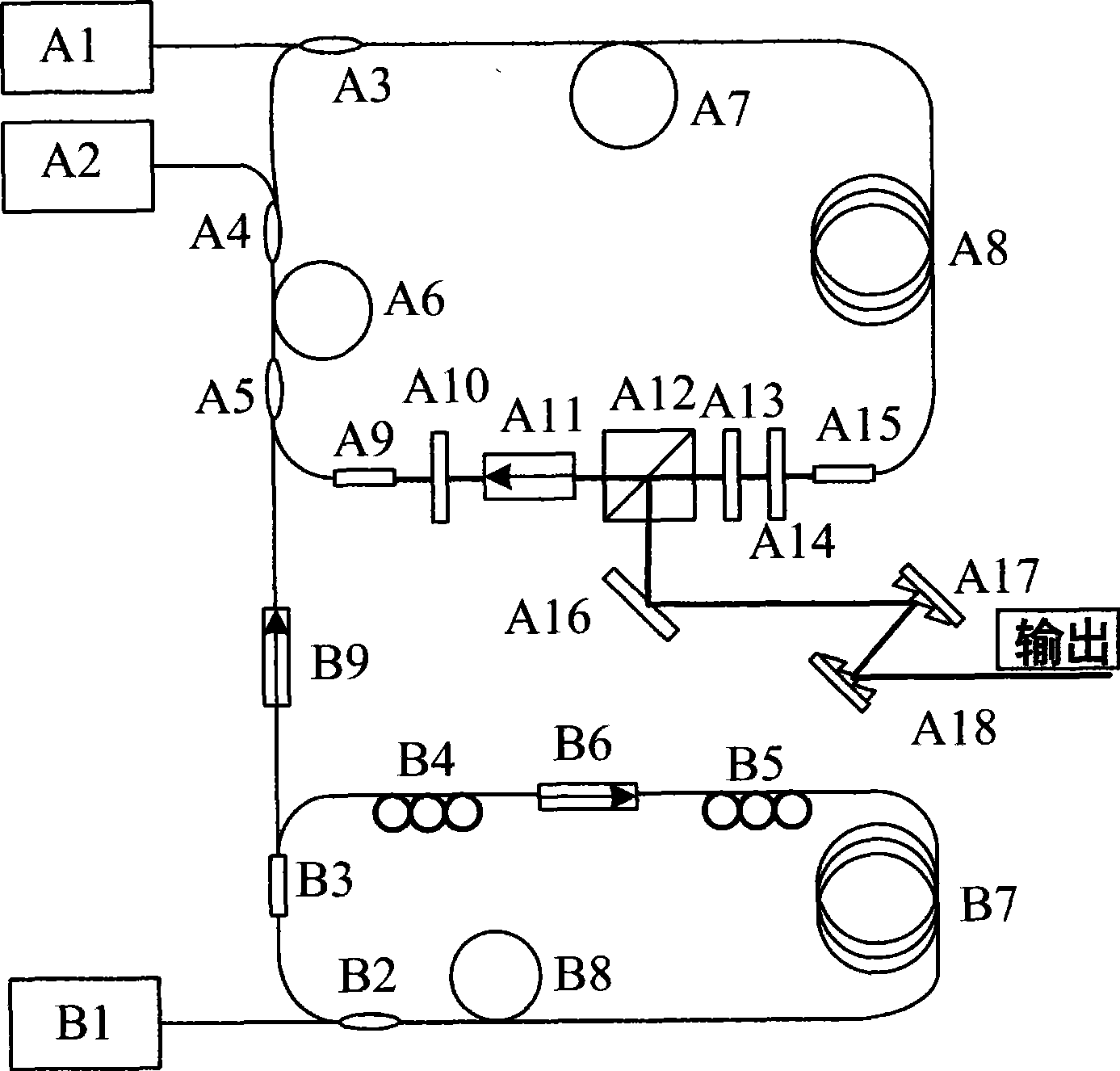

[0013] The features of the present invention and other related features will be further described in detail below in conjunction with the accompanying drawings through embodiments, so as to facilitate the understanding of those skilled in the art:

[0014] as attached Figure 1-2 As shown, the symbols in the figure respectively represent: Ytterbium-doped fiber laser A, semiconductor laser A1, semiconductor laser A2, 980nm / 1064nm wavelength division multiplexer A3, 980nm / 1064nm wavelength division multiplexer A4, 1064nm / 1550nm wavelength division multiplexer A5, erbium-doped fiber A6, ytterbium-doped fiber A7, single-mode fiber A8, fiber collimator A9, 1064nm 1 / 4 wave plate A10, spatial polarization related optical isolator A11, polarization beam splitter A12, 1064nm 1 / 2 wave plate A13, 1 / 4 wave plate A14 of 1064nm, fiber collimator A15, 1064nm high reflection mirror A16, grating A17, grating A18, erbium-doped fiber laser B, semiconductor laser B1, 980nm / 1550nm wavelength divis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com