Vertical pipe expander capable of automatically locating and clamping

An automatic positioning and expanding machine technology, applied in the field of vertical pipe expanders, can solve the problems of low production efficiency, complicated clamping and positioning, etc., and achieve the effect of improving productivity and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

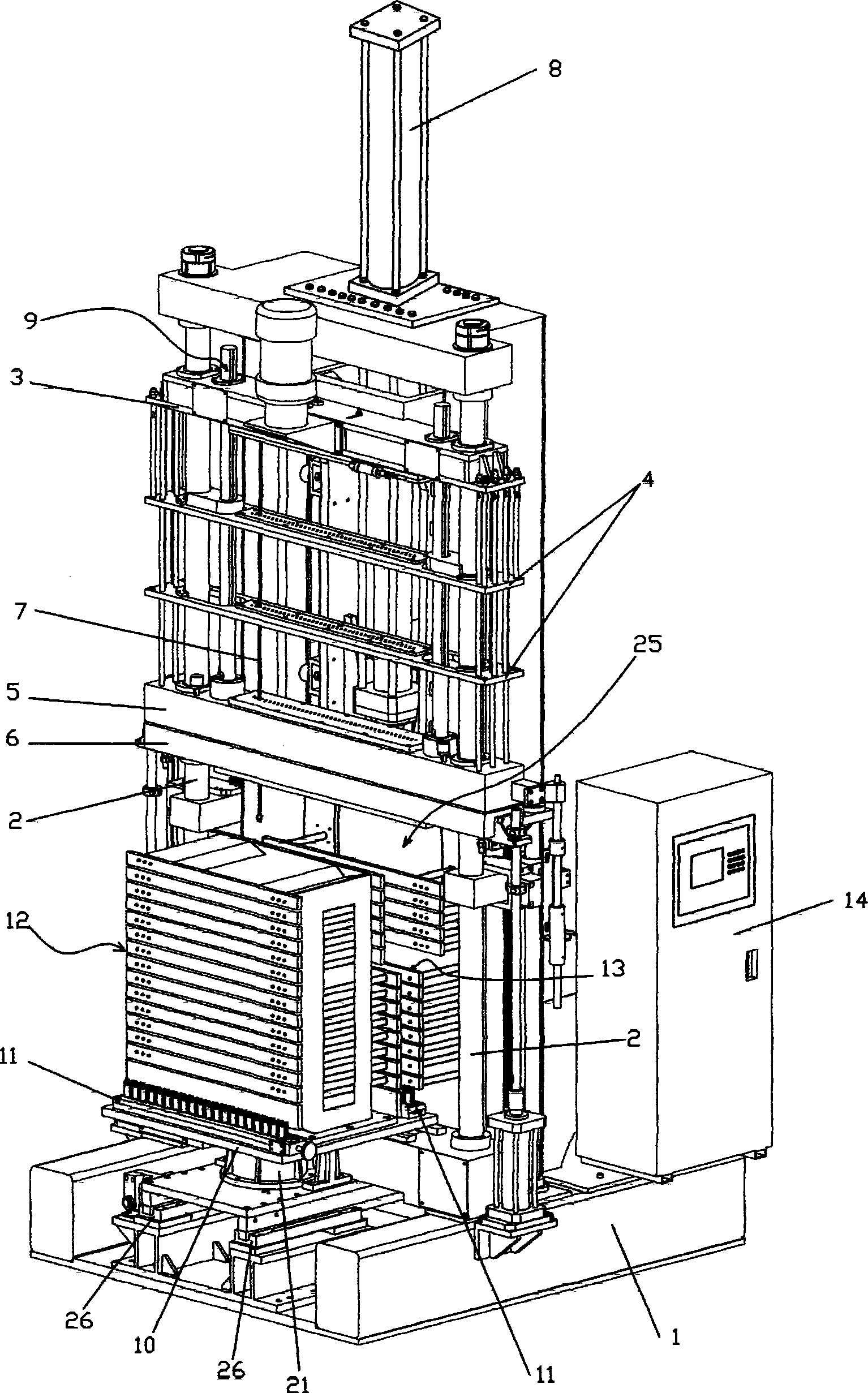

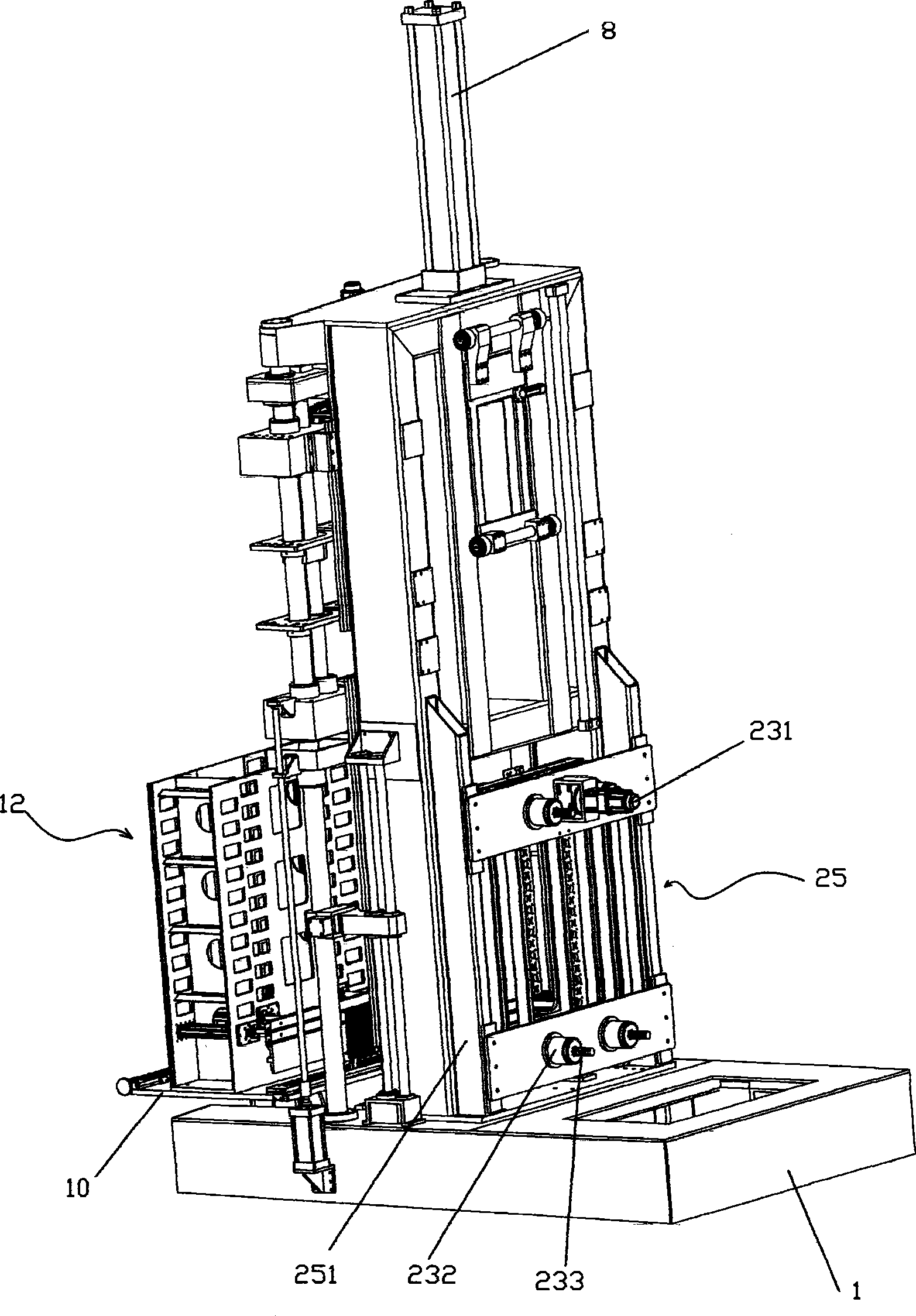

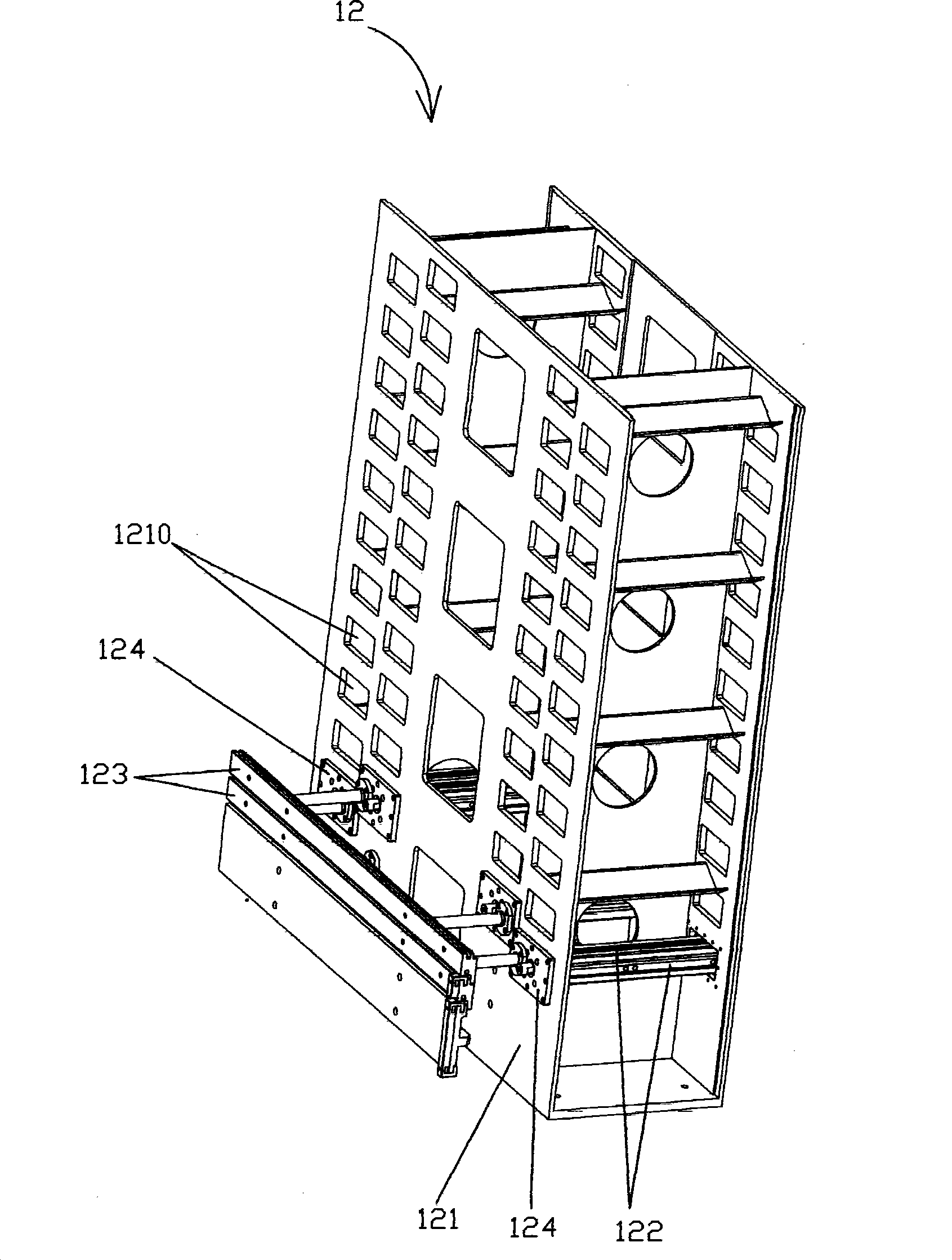

[0019] Such as figure 1 , figure 2 As shown, a vertical tube expander capable of automatic positioning and clamping includes a frame 1 on which two parallel guide posts 2 are vertically arranged, and a main oil cylinder 8 is provided on one side of the guide posts 2, The guide column 2 is sheathed with an expansion rod mold base 3 connected to the piston rod of the main oil cylinder 8, and the expansion rod mold base 3 is provided with an expansion rod 7; it also includes a stroke control mechanism 9 that can control the expansion rod mold base 3, The execution command of the stroke control mechanism 9 is issued by a controller 14; the expansion rod guide plate 4, the expansion die base 5, and the stripping plate 6 are connected in sequence under the expansion rod mold base 3; The rotary table 10 is provided with a workpiece positioning plate 11 and ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap