Rotating cage type belt pulley of continuously variable transmission

A technology of working radius and pulley, which is applied in the direction of belt/chain/gear, elements with teeth, portable lifting devices, etc., to achieve the effect of reducing axial size, reducing strength and improving the range of change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

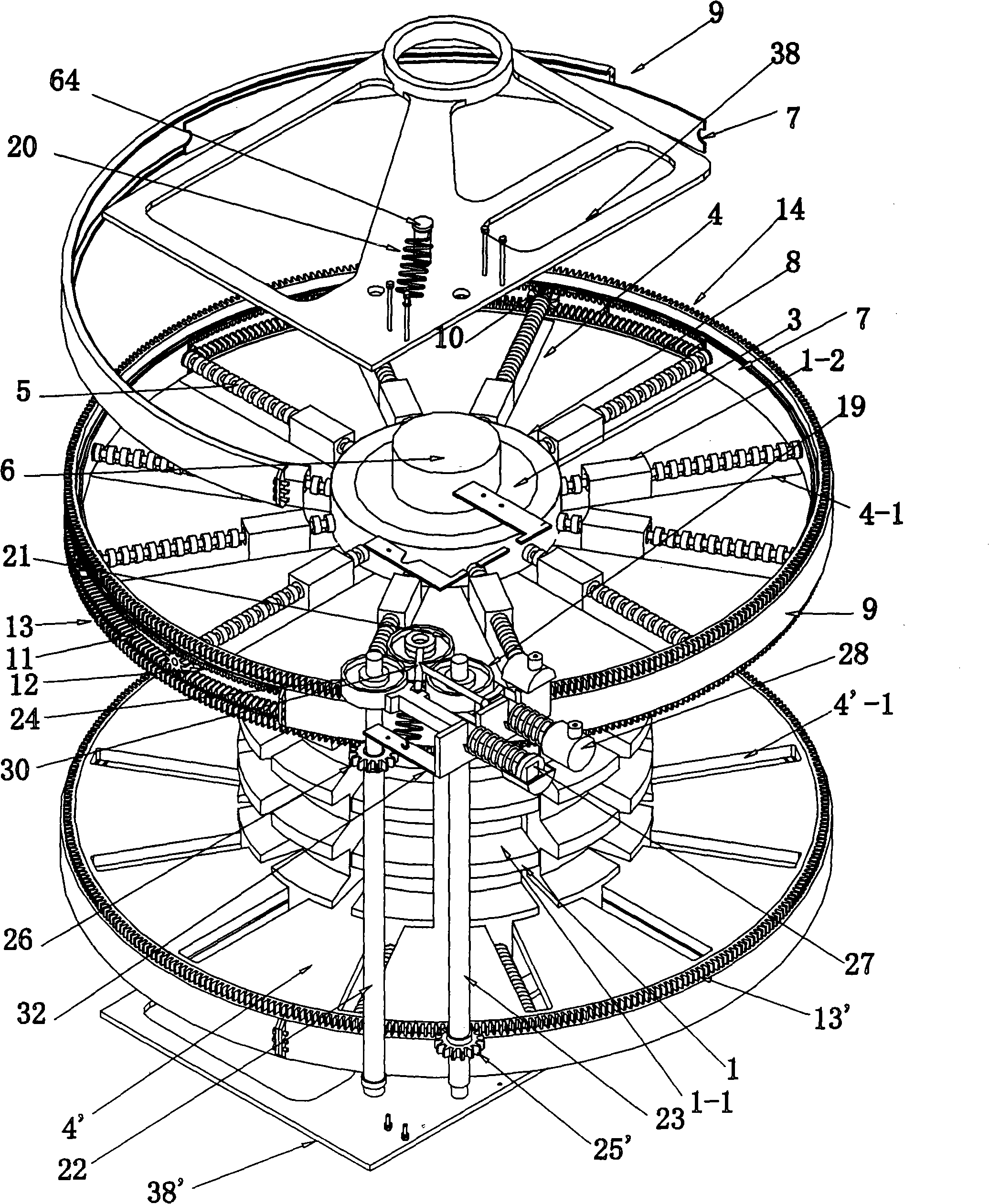

Embodiment 1

[0042] see Figure 5 , in a CVT composed of a pair of tumbler pulleys connected by the belt 2, when the working radius of the active tumbler pulley gradually decreases, the belt 2 starts to loosen, and the belt tensioner 35 is under the pressure of the tension spring 33 Under the action, move inwardly, pressure has sent out slack positioning sensor 40, and slack positioning sensor 40 sends signal to the second hydraulic cylinder 28 ' of another rotating cage pulley as driven wheel and carries out the same operation as above-mentioned driving wheel. The railing moves radially, but in the opposite direction, and the working radius gradually increases. When the belt 2 returns to the tensioned state, the slack positioning sensor 40 returns to its original state, and the second hydraulic cylinder 28' of the passive rotating cage pulley stops working, so that the active The reduction of the working diameter of the rotating cage pulley and the large variation of the working diameter ...

Embodiment 2

[0047] This embodiment is still the deformation of embodiment two, and the slide block 1-2 with the screw hole of its railing 1 is positioned at the middle part of railing 1 (referring to Figure 6 ), the band groove 1-1 on the railing 1 peripheral surface is located at the both sides of the railing 1, therefore, the torque disc 4, the spoke wheel, and the radius positioning control device are also centrally arranged, and its working process is the same as that of the second embodiment.

Embodiment 3

[0049] see Figure 7 As shown, the difference between the rotating cage pulley of this embodiment and the first to third embodiments is that the railing 1 and the screw 5 are divided into two groups of railing 1a and railing 1b, screw 5a and screw 5b at corresponding intervals, and the arc shape of the railing 1b The perimeter of the peripheral surface is less than the perimeter of the railing 1a, the screw rod 5b is engaged with an indicator 57, and the distance between the planetary positioning gear 10 on the screw rod 5b and the center of the wheel shaft is greater than the distance between the planetary positioning gear 10 on the screw rod 5a and the wheel shaft. The planetary positioning gear 10 arranged on the screw rod 5 a is only in mesh with the outer bevel gear 12 , the outer bevel gear 12 has no extended outer gear ring, and is provided with a retaining ring 15 and a screw lock. This retaining ring 15 is fixed with the torque disc 4 by means of screws, bolts or rive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com