Machine for testing circuit board

A technology for testing machines and circuit boards, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of troublesome operation of flexible circuit boards, hidden safety hazards, inconvenient operation, etc. Improve the feeding efficiency, simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

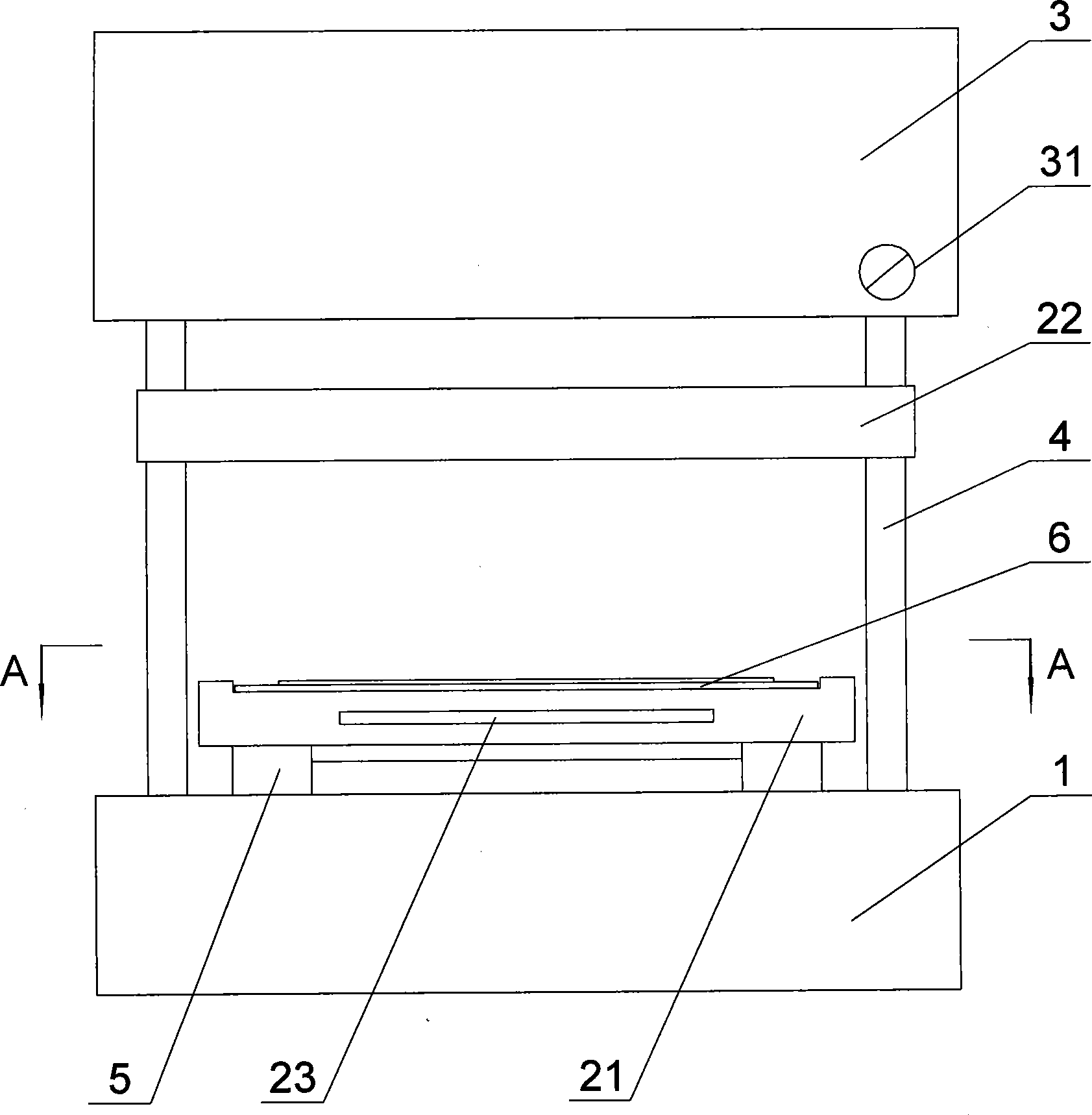

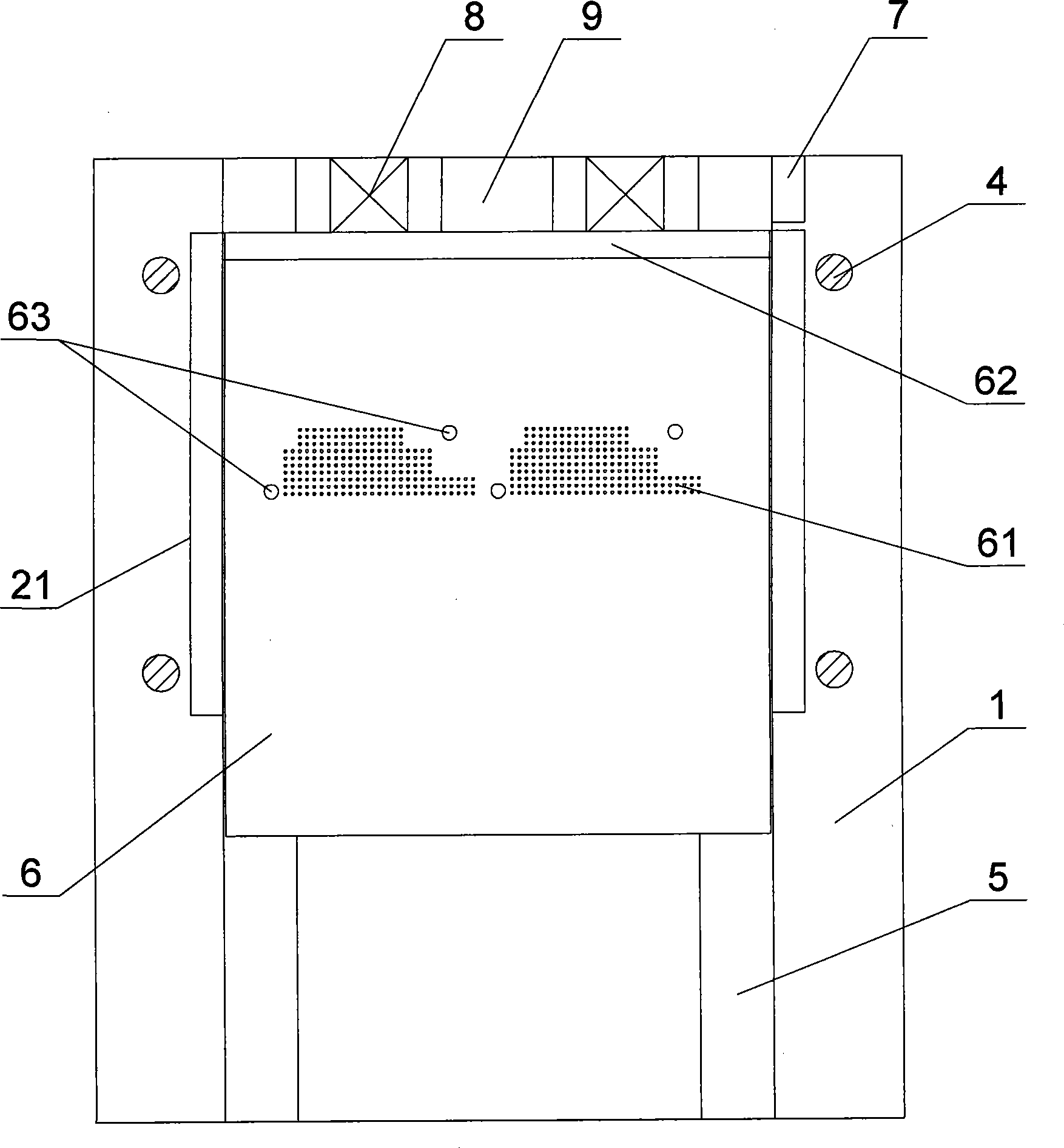

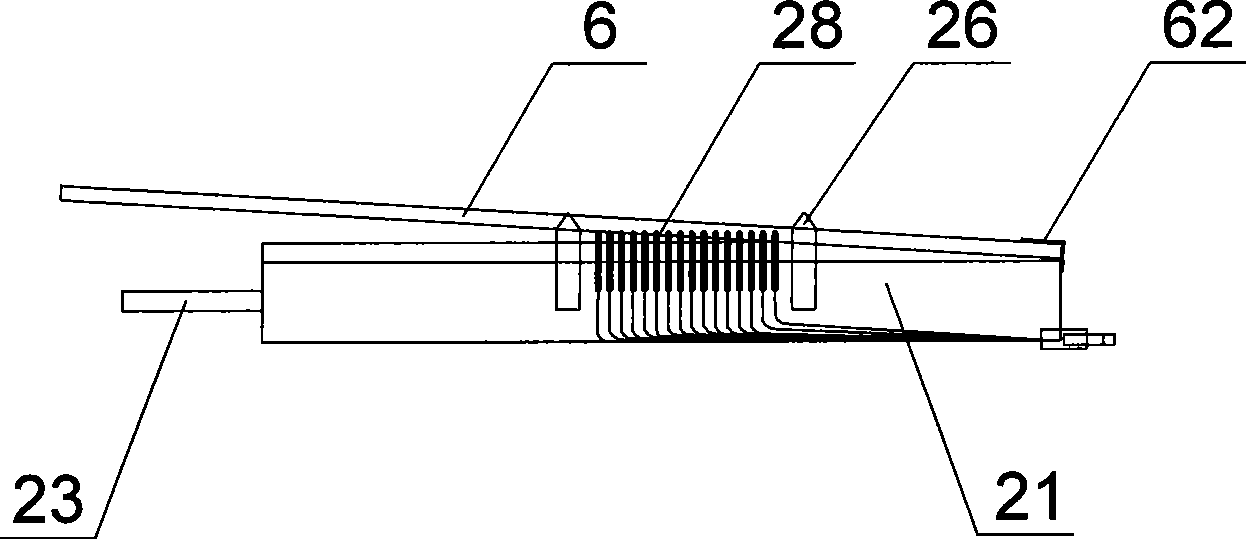

[0028] like Figure 1 ~ Figure 3 As shown, the present invention includes a base 1, a lower mold assembly 21, an upper mold assembly 22, a motor and an electric control device 3, and a stripping plate 6, and four columns 4 are fixedly connected to the base 1, and the upper mold assembly 22 is slidably connected with the four columns 4, the lower mold assembly 21 is matched with the upper mold assembly 22, and the upper mold assembly 22 and the lower mold assembly 21 are provided with Test pin 28, two parallel slide rails 5 are arranged on the base 1, the lower mold assembly 21 is slidably connected with the slide rails 5, and the stripper plate 6 is located on the upper mold assembly 22 Between the lower mold assembly 21, the stripper plate 6 is provided with a test pinhole 61, and the front part of the stripper plate 6 is rotatably connected with the lower mold assembly 21 through a connecting piece 62, The rear portion protrudes from the side of the lower mold assembly 21, ...

Embodiment 2

[0033] like figure 1 , figure 2 , Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the circuit board testing machine of this embodiment also includes a first electromagnet 10 and a return spring 11, and the first electromagnet 10 is located in the lower module part 21 and connected to the lower surface of the stripper plate 6 through the return spring 11, the first electromagnet 10 and the return spring 11 can realize the process of popping off the stripper plate 6 Automatic control reduces labor even more.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com