Distributed Bragg reflection type single frequency optical fiber laser based on phase shifting optical fiber grating

A phase-shifted fiber grating and distributed Bragg technology, applied in lasers, laser parts, phonon exciters, etc., can solve difficult debugging, laser power output can not meet the needs of practical applications, can not obtain high-power single-frequency laser output and other issues, to achieve the effect of simple structure, low power consumption and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

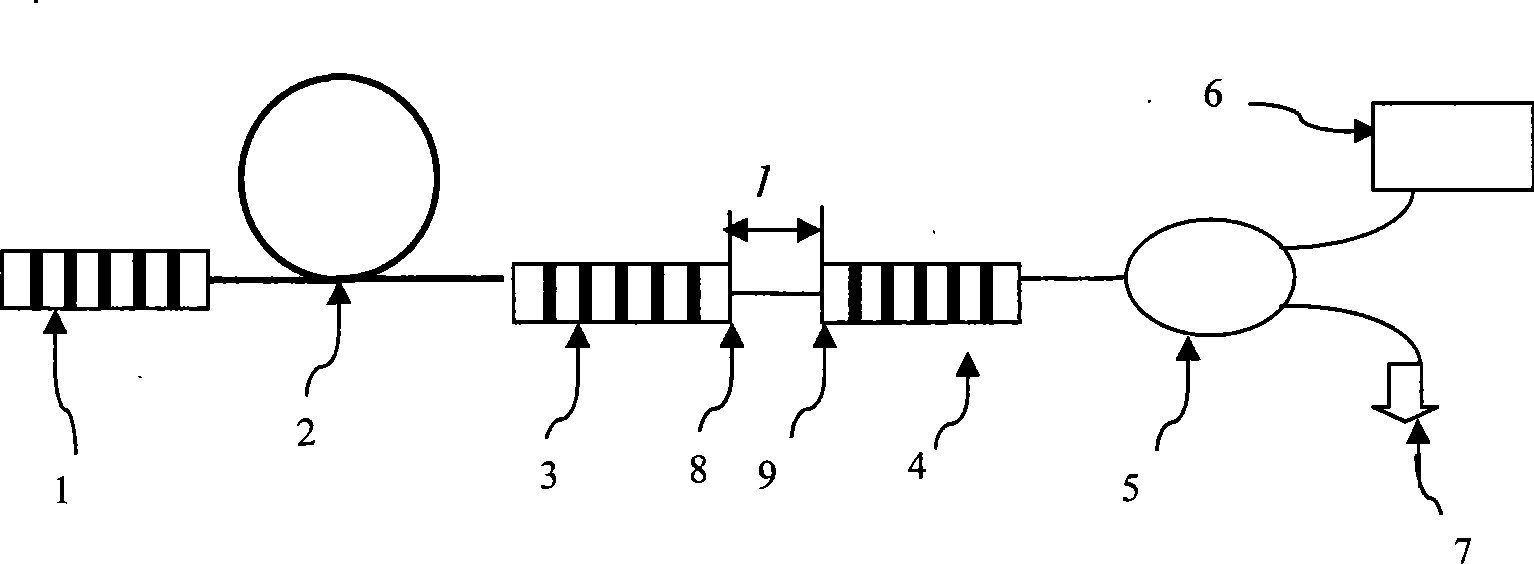

[0041] The structure of embodiment 1 is as figure 1 As shown, the manufacturing method of the present embodiment is to select a longer high-concentration doped fiber 2 according to the actual needs of the output power of the single-frequency fiber laser of the present invention, and weld a fiber grating 1 at one end thereof, and weld a phase-shifting fiber grating at the other end 3 and fiber grating 4. The phase-shifting fiber grating 3 and the fiber grating 4 are fabricated on one optical fiber at the same time, and it must be ensured that the cavity length l of the equivalent FP cavity satisfies the value of formula 3.

Embodiment 2

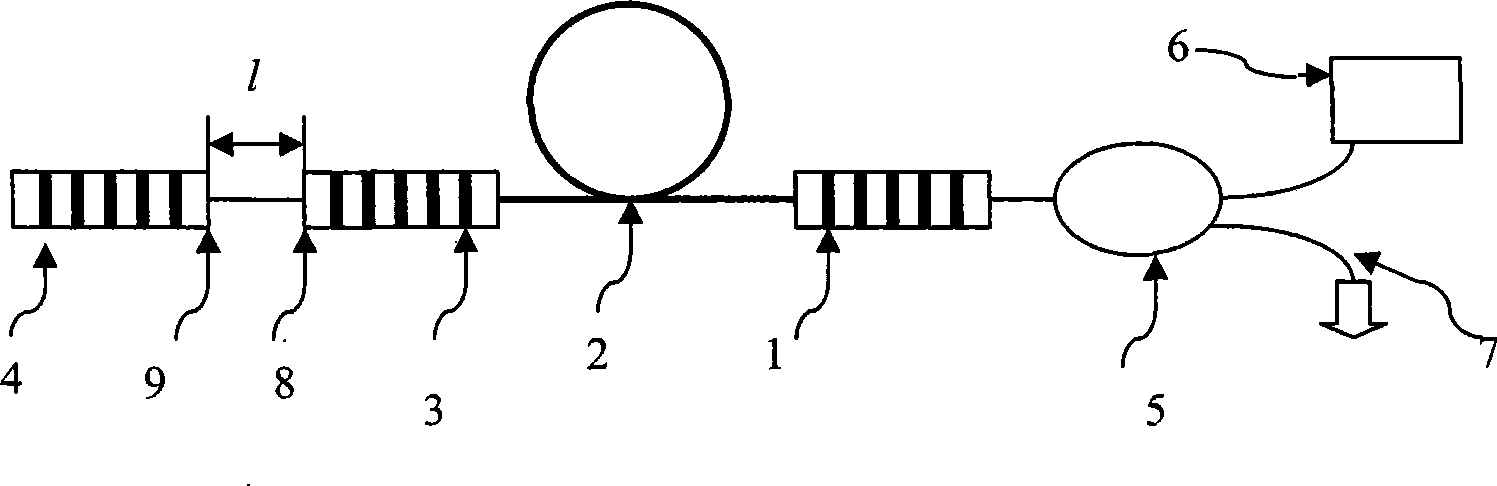

[0043] The structure of embodiment 2 is as figure 2 As shown, it can be seen from the figure that this embodiment is based on a phase-shifted fiber grating distributed Bragg reflection single-frequency fiber laser, which is characterized in that a high-concentration doped fiber 2 is used as a laser gain medium, and the high-concentration doped fiber 2 One end of the fiber Bragg grating 1 is welded, and the other end is welded to form an equivalent FP cavity consisting of a phase-shifted fiber Bragg grating 3 and a fiber Bragg grating 4; the pump source 6 is connected to the λ of the wavelength division multiplexer 5 1 port, the hybrid port of the wavelength division multiplexer 5 is connected to the fiber grating 1, and the λ of the wavelength division multiplexer 5 2 The port is the laser output port 7.

[0044] The equivalent FP cavity composed of the phase-shifted fiber grating 3 and the fiber grating 4 satisfies the following relationship:

[0045] l ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com