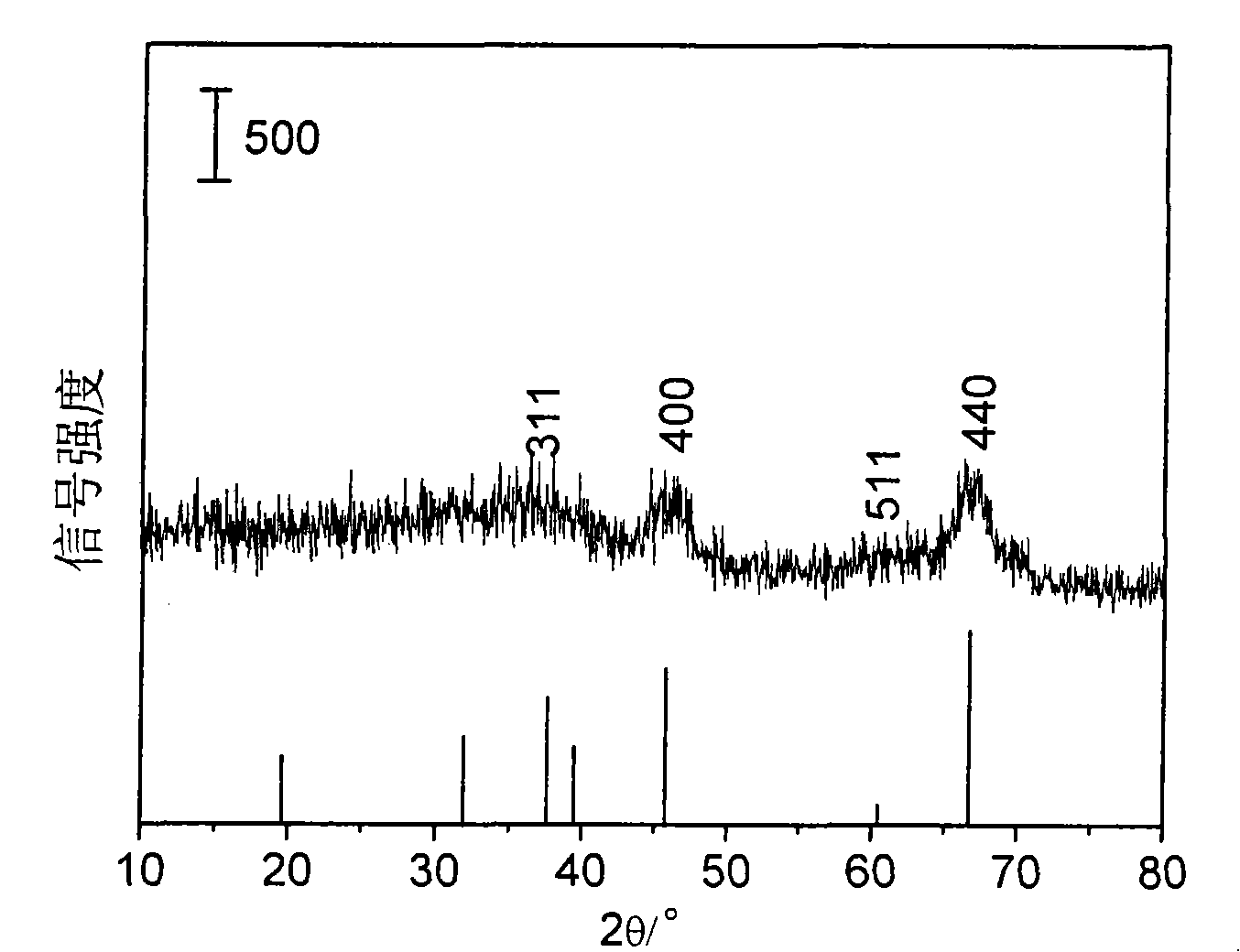

Method for simply synthesizing gamma-Al2O3 and use thereof in ethanol dehydration

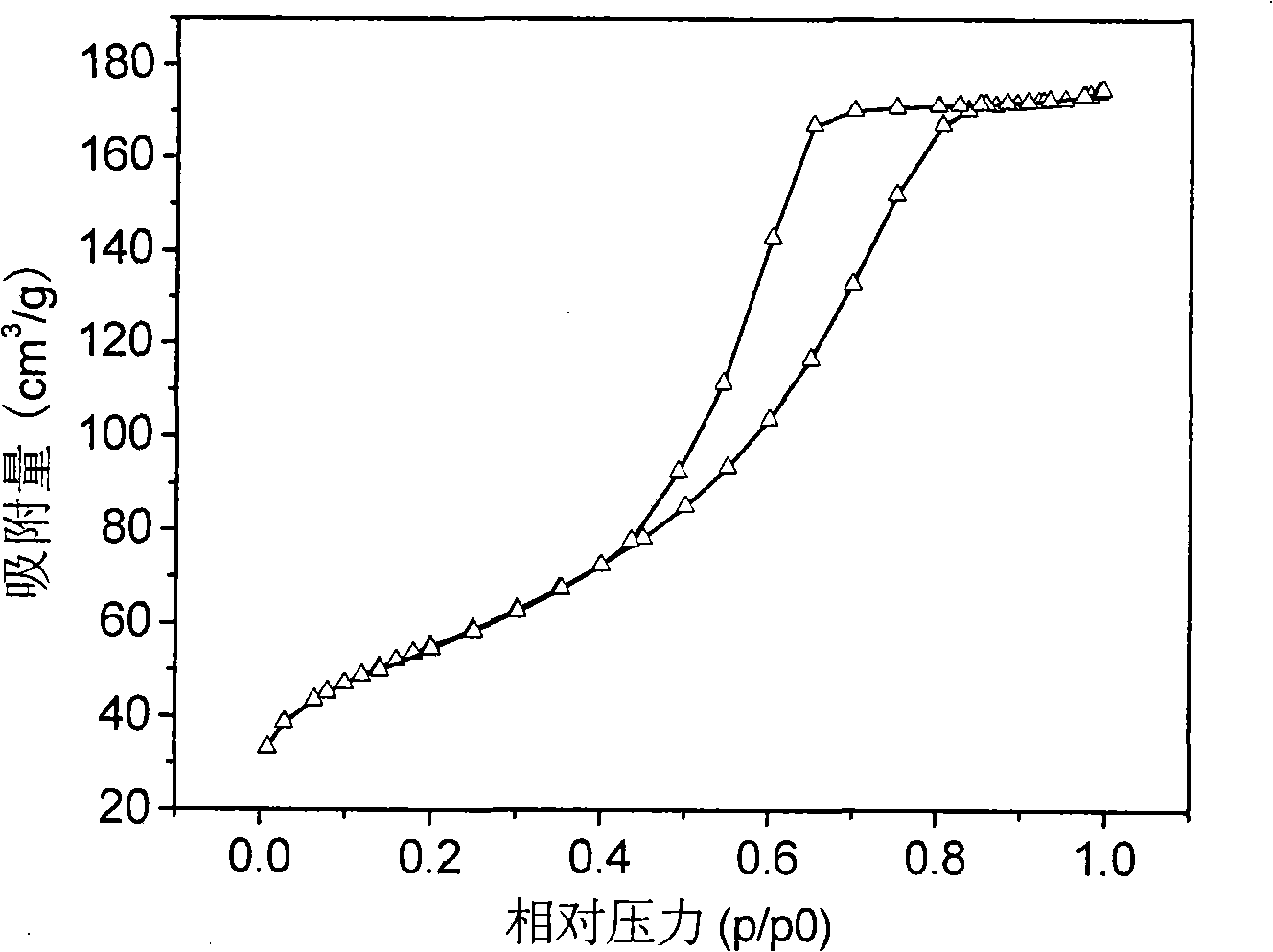

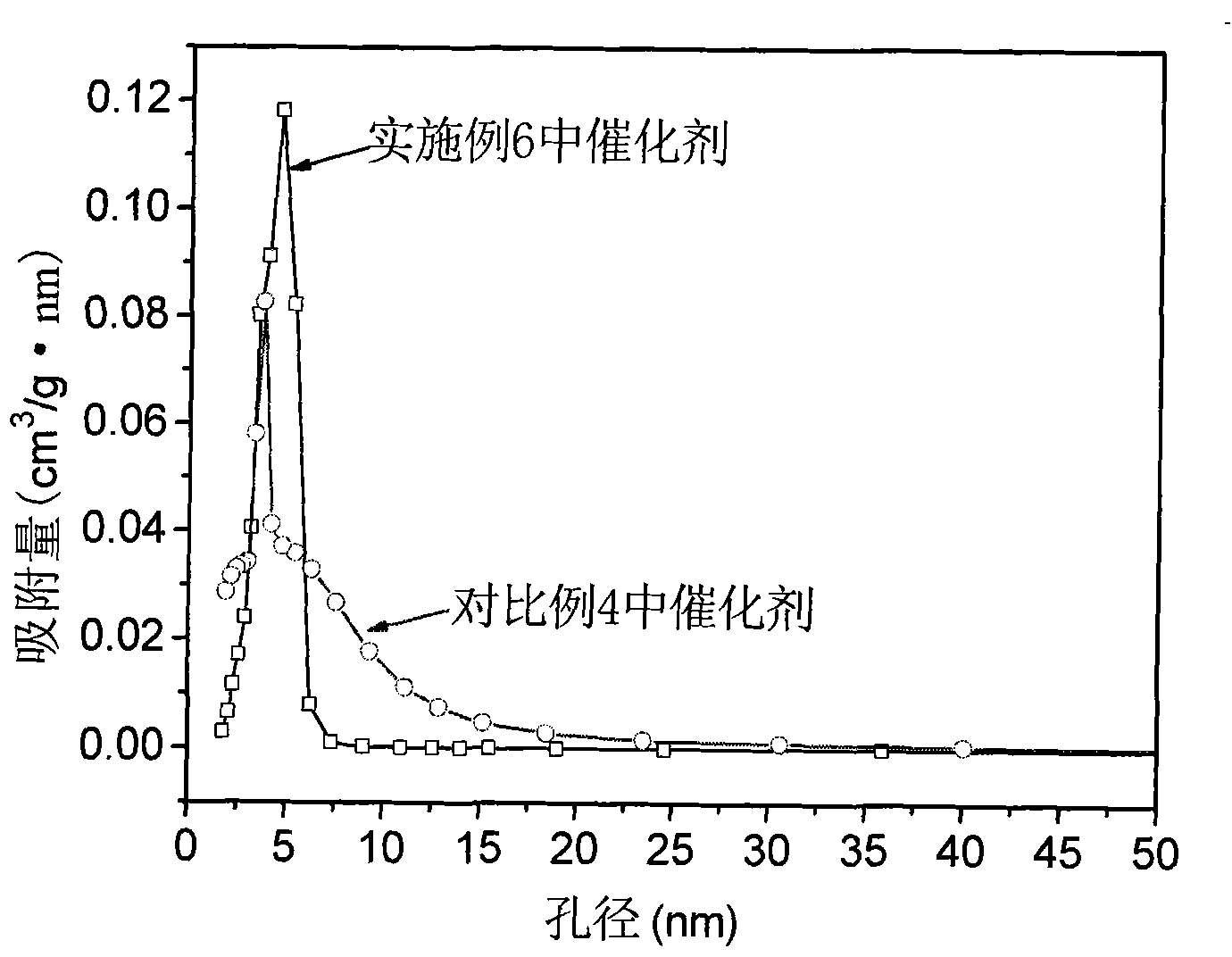

A simple, aluminum alkoxide technology, applied in chemical instruments and methods, hydrocarbon production from oxygen-containing organic compounds, organic chemistry, etc., can solve problems such as complex processes or devices, difficult to remove, wide pore distribution, etc., to achieve good activity and The effect of selectivity, good activity and selectivity, uniform pore size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Weigh 36.75g Al(NO 3 ) 3 9H 2 O, set the volume to 250ml, make a 0.6mol / L solution, use 6mol / L urea aqueous solution as precipitant, add Al(NO 3 )3 9H 2 In O solution, adjust the pH to 8-9. After the precipitation is completed, the slurry is stirred at room temperature for 0.5 h, filtered, and the filter cake is dried overnight at 120 ° C, and then calcined in a muffle furnace at 600 ° C for 4 h to obtain γ- al 2 o 3 . 30~50 mesh γ-Al 2 o 3 1.5g of catalyst is loaded into the constant temperature section of the fixed-bed reactor, and the rest is filled with quartz sand. -1 N 2 The bed temperature was raised to 350°C under the air flow rate, and then the 92wt% ethanol solution was added for 0.6h -1 The mass space velocity is injected into the system, and the generated gas and liquid are sampled and analyzed. The results are shown in Table 1.

Embodiment 2

[0035] Weigh 91.88g of aluminum isopropoxide, set the volume to 250ml, make a 1.5mol / L solution, stir at room temperature and add 5mol / L precipitant NH 3 ·H 2 O solution, adjust PH=8~9, after the precipitation is completed, stir the slurry at room temperature for 1h, filter, wash until pH=7, dry the filter cake at 120°C overnight, then place it in a 600°C muffle furnace for calcination for 4h , to get γ-Al 2 o 3 . 30~50 mesh γ-Al 2 o 3 1.5g of catalyst is loaded into the constant temperature section of the fixed-bed reactor, and the rest is filled with quartz sand. -1 N 2 The bed temperature was raised to 380°C under the gas flow rate, and then the 92wt% ethanol solution was added for 1.2h -1 The mass space velocity is injected into the system, and the generated gas and liquid are sampled and analyzed. The results are shown in Table 1.

Embodiment 3

[0037] Weigh 36.75g Al(NO 3 ) 3 9H 2 O, dilute to 250ml, make a 0.6mol / L solution, and use 6mol / L NH 3 ·H 2 O is a precipitant, adding Al(NO 3 ) 3 9H 2 In the O solution, adjust the pH to 8-9. After the precipitation is completed, the slurry is stirred at room temperature for 2 hours, filtered, and the filter cake is dried at 120°C overnight, and then calcined in a muffle furnace at 600°C for 6 hours to obtain γ-Al 2 o 3 . 30~50 mesh γ-Al 2 o 3 1.5g of catalyst is loaded into the constant temperature section of the fixed-bed reactor, and the rest is filled with quartz sand. -1 N 2 The bed temperature was raised to 400°C under the air flow rate, and then the 92wt% ethanol solution was added for 5h -1 The mass space velocity is injected into the system, and the generated gas and liquid are sampled and analyzed. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com