Novel polymer sand fixing agent

A technology of sand-fixing agent and polymer, which is applied in the field of new-type polymer sand-fixing agent and its synthesis, can solve the problem of high cost of sand-fixing agent, achieve good application value and promotion prospect, improve the effect of pressure resistance and strong mechanical operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

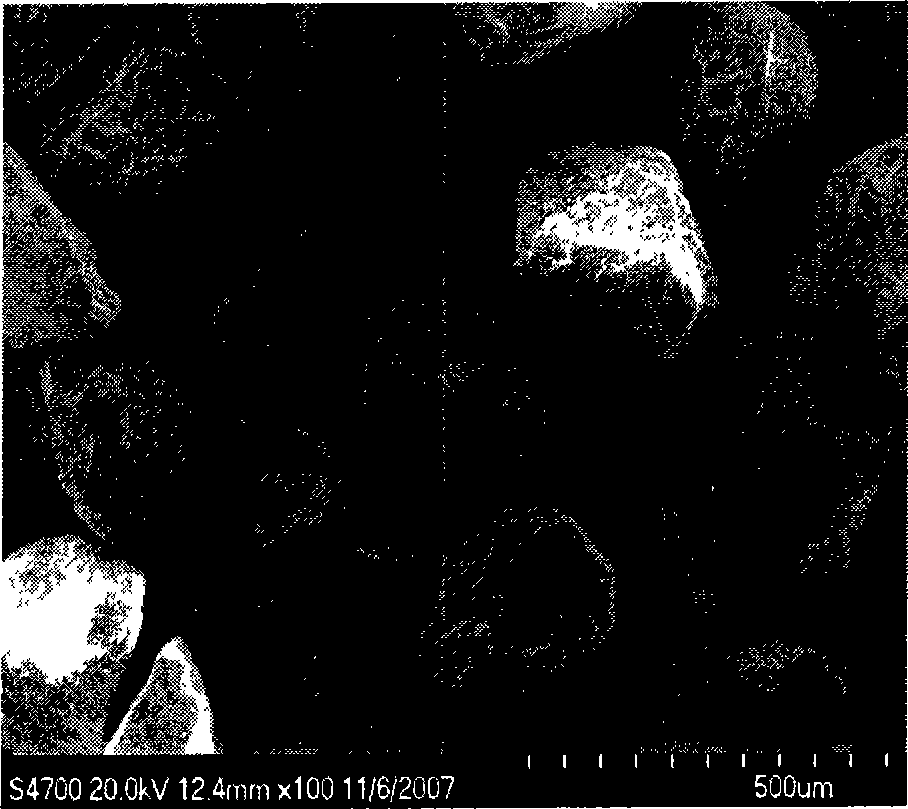

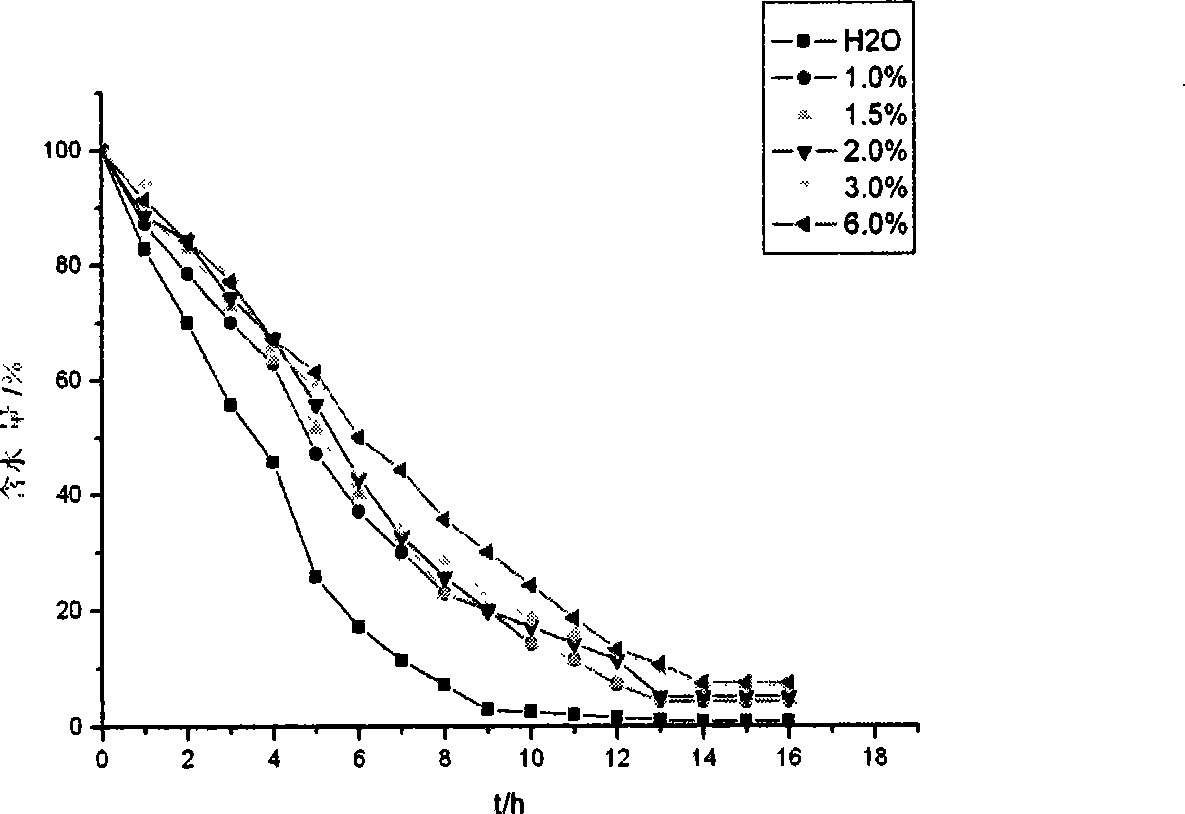

Image

Examples

Embodiment 1

[0018] a. to dissolve, to mix

[0019] Take 40 parts of deionized water and 0.9 parts of polyvinyl alcohol and put them into the reactor to heat and stir to dissolve them. When the temperature drops to 50°C, add 0.3 parts of sodium dodecylbenzenesulfonate and 0.9 parts of Tween-600, and stir to make them fully mix;

[0020] b. Pre-emulsification

[0021] Add 2.5 parts of butyl acrylate and 5 parts of vinyl acetate to the above mixture, and stir at 50°C for 20 minutes;

[0022] c. Polymerization

[0023] Raise the temperature of the above mixture to 60-70°C, add 5 parts of 1.5% potassium persulfate solution, initiate the reaction for 30-40 minutes, then raise the temperature to 75-85°C, add dropwise 15 parts of 1.5% potassium persulfate solution and 7.5 parts of acrylic acid Mix monomers of butyl ester and 15 parts of vinyl acetate, keep the initiator and the monomer mixture dripped out synchronously, react for 4 hours, then raise the temperature to 85-95°C and keep it for 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com