Method for improving binding alignment accuracy of shadow mask type plasma display screen

A technology of plasma and alignment accuracy, which is applied in the manufacture of ships or lead-in wires, etc., can solve the problems of reducing the binding yield, affecting the binding efficiency, and the inability to accurately correspond between the substrate electrode and the FPC electrode, so as to improve stability and adjustability, improve adaptability, and achieve effective control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

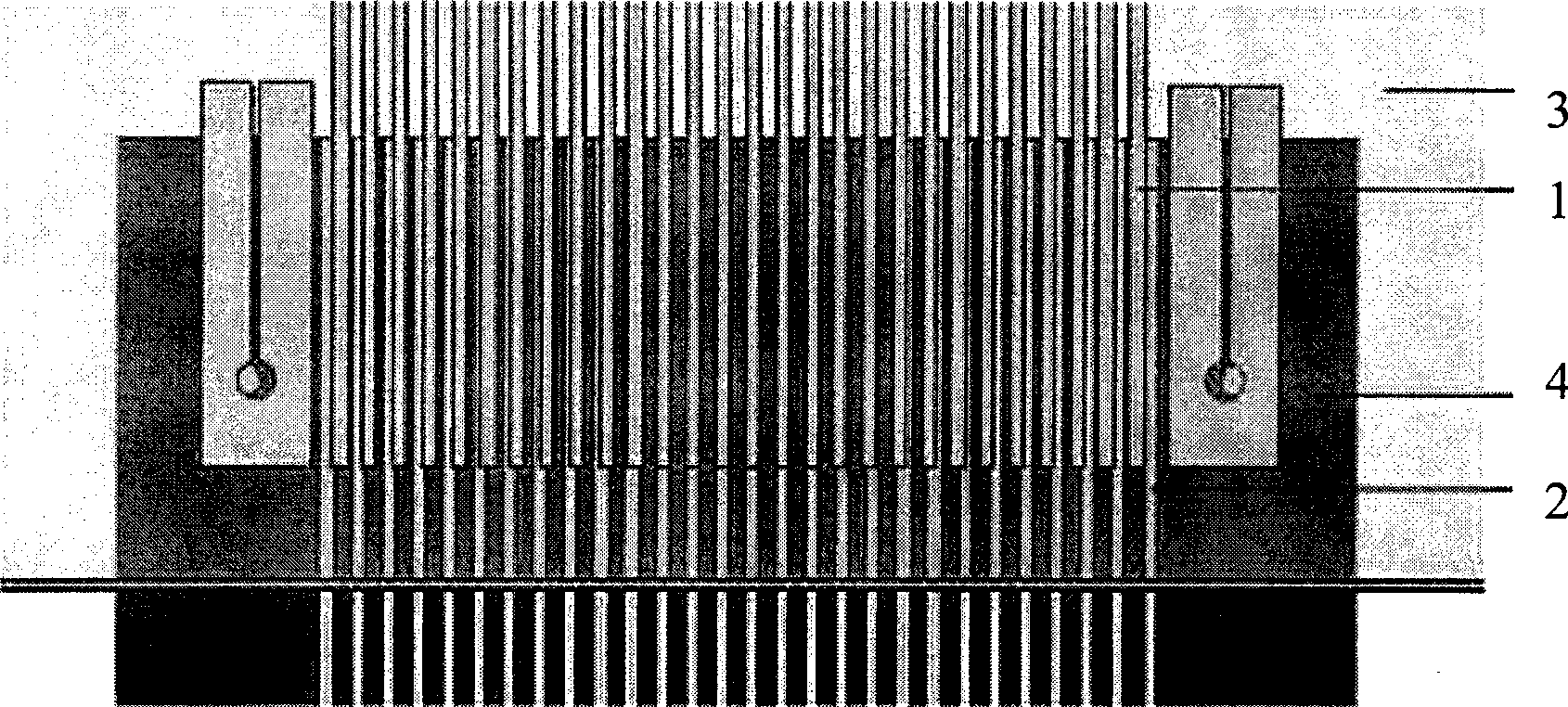

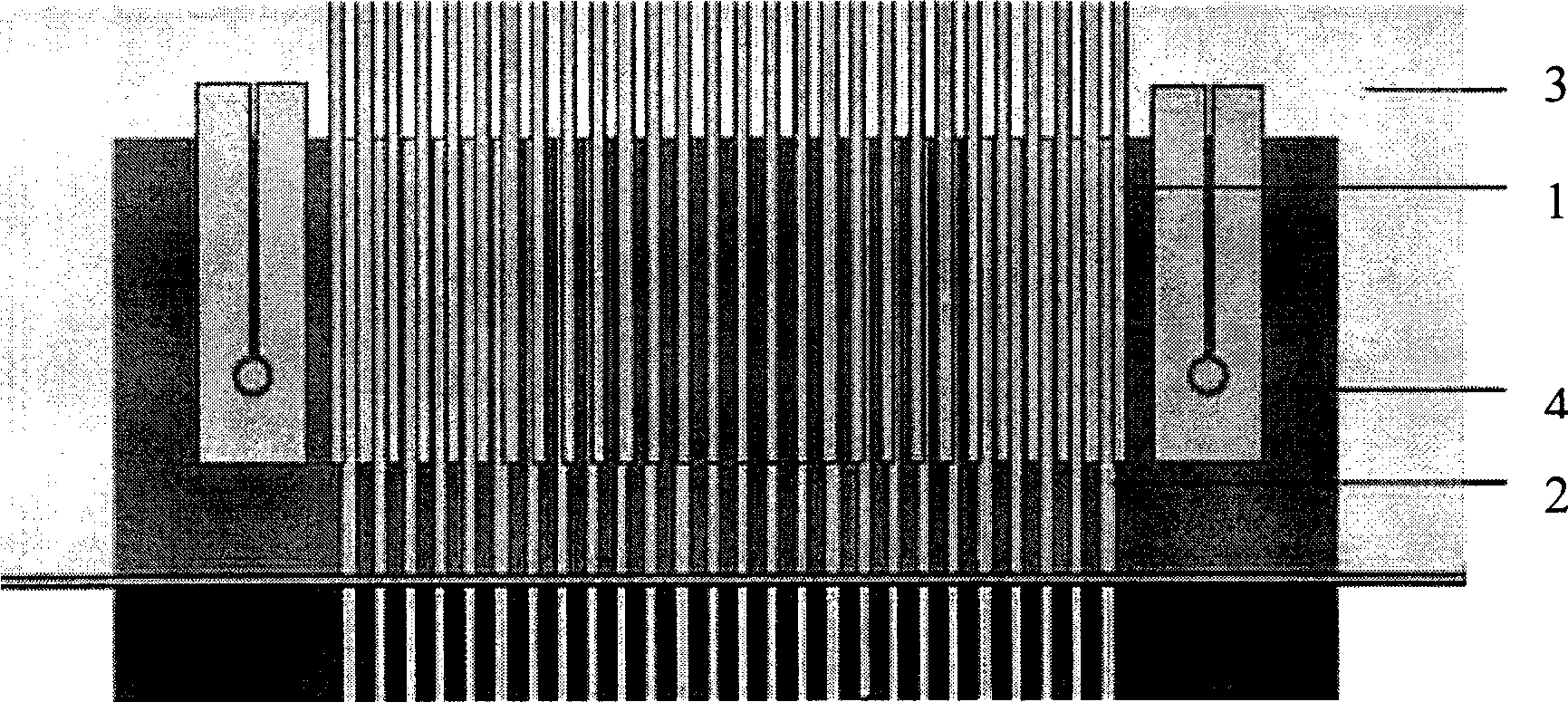

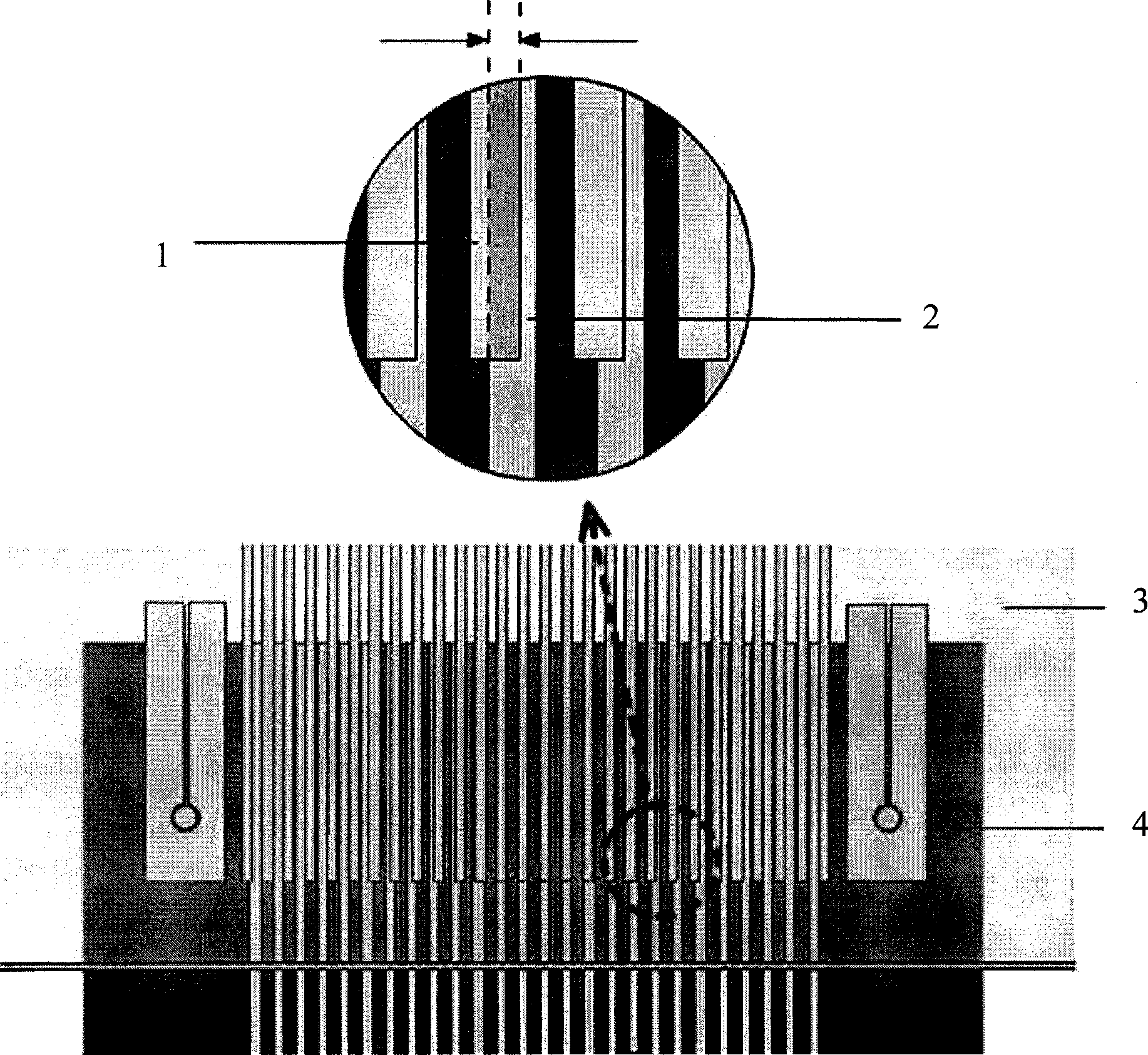

[0027] As shown in the figure, a method for improving the bonding alignment accuracy of a shadow mask type plasma display screen includes the following steps:

[0028] (a). When binding the shadow mask plasma display screen, set the temperature of the pressure head of the automatic alignment binding machine to ensure that the actual temperature of the pressure head is 200℃≥T c ≥180°C, 200°C and 180°C are the limit temperature for binding, 200°C is the upper limit temperature for binding, and 180°C is the lower limit temperature for binding;

[0029] (b). After the automatic alignment binding machine completes the binding, it detects that when it is detected that the substrate electrode 1 on the substrate 3 and the flexible circuit board electrode on the flexible circuit board, that is, the FPC electrode 2, are aligned accurately, it will also That is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com