Valve device

A valve device and valve rod technology, which is applied in the direction of valve device, valve lift, valve details, etc., can solve the problem of brittle failure of the welding part of the valve rod, and achieve the effect of improving reliability and preventing peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

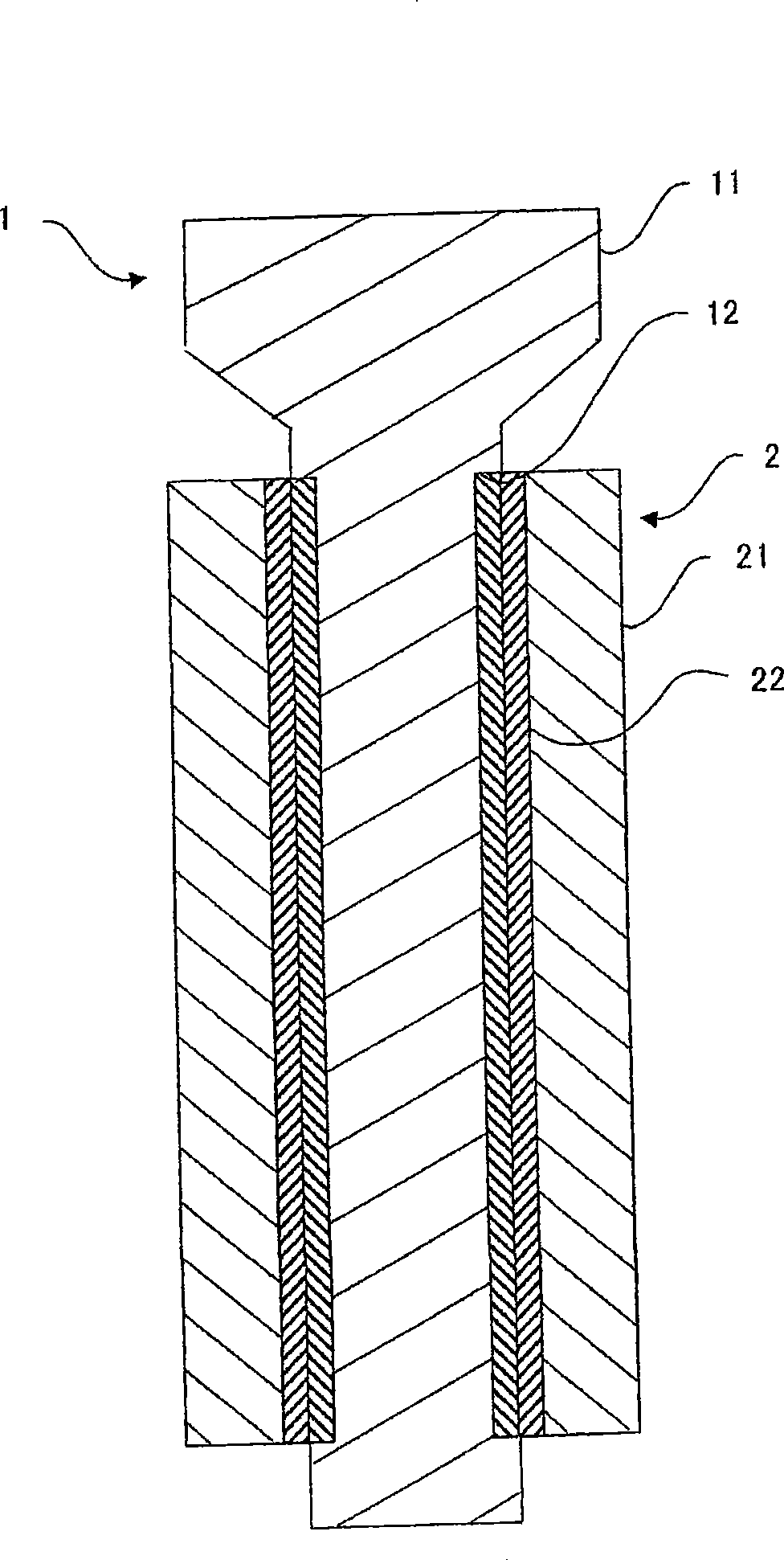

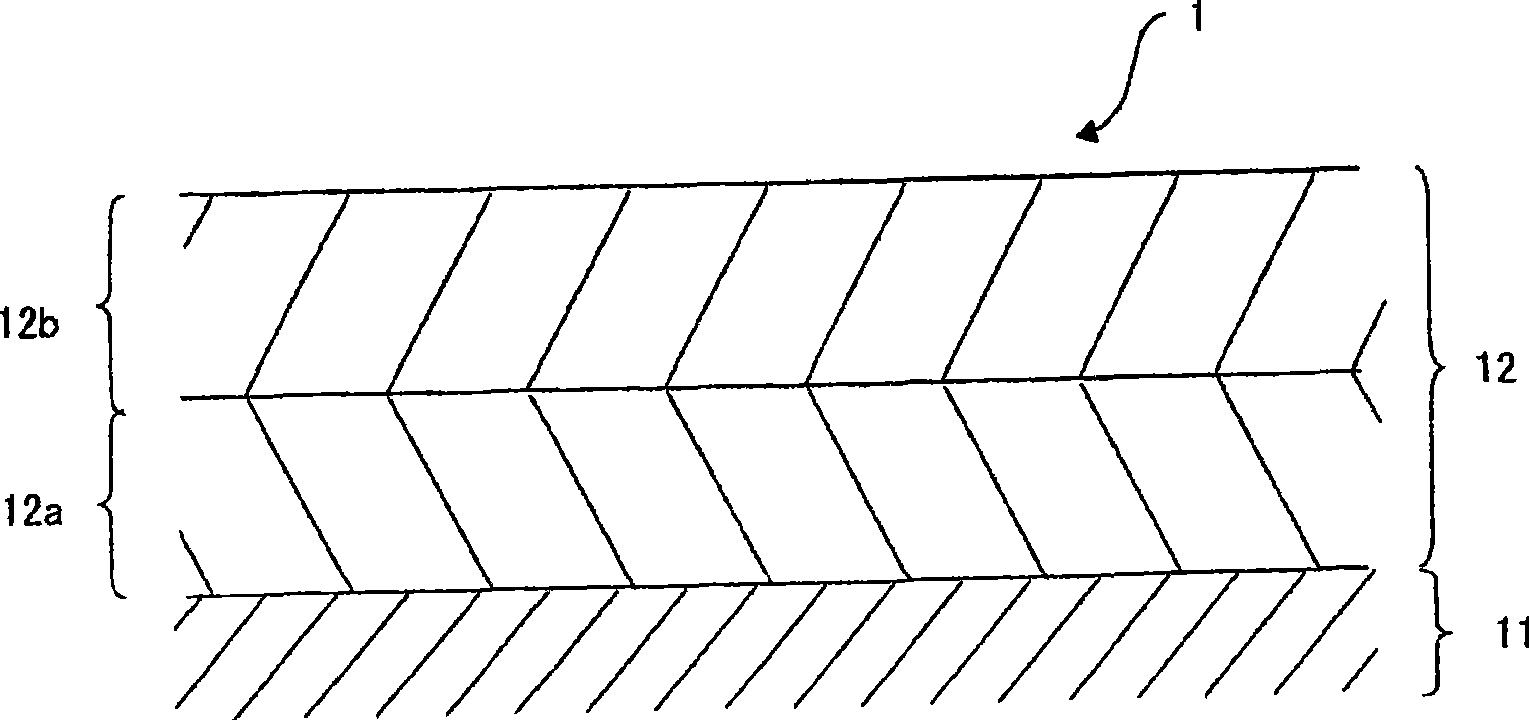

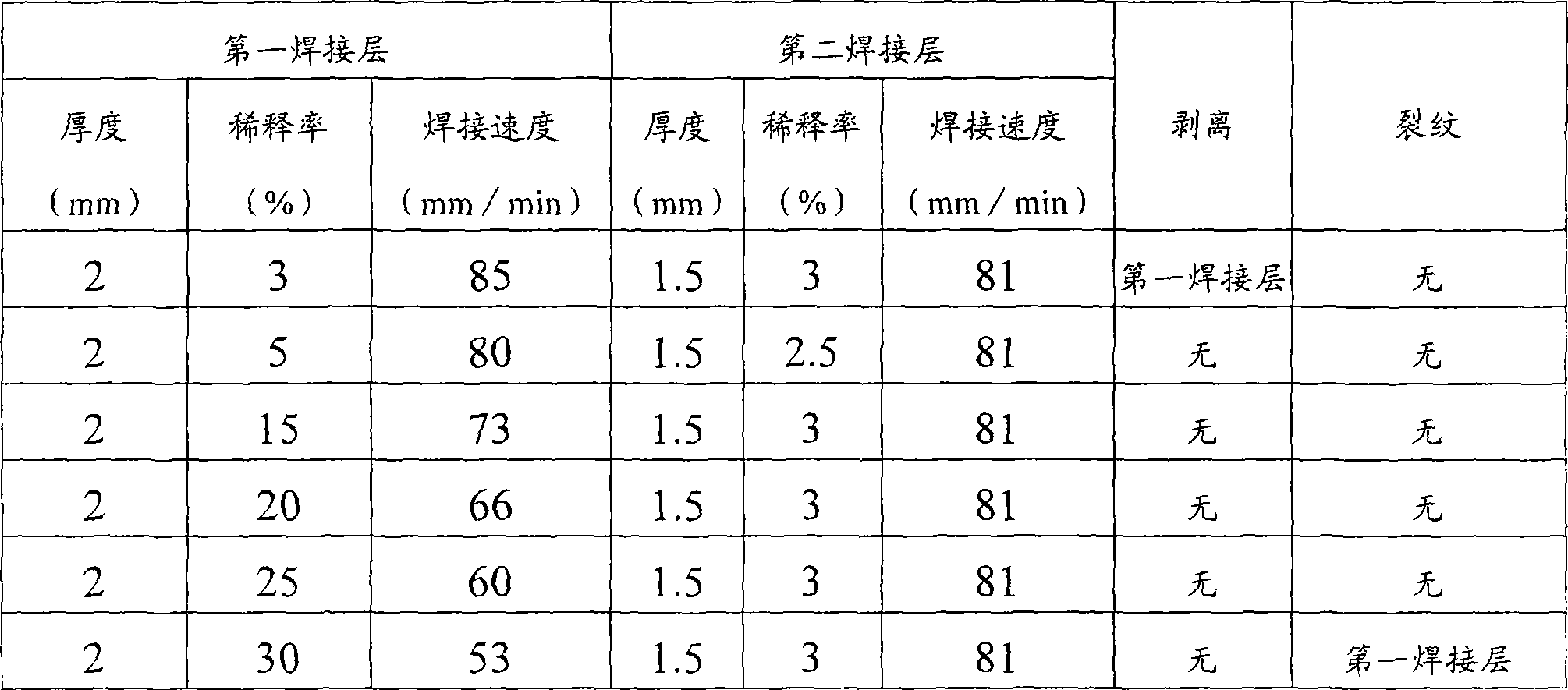

[0055] 1.2%Cr-0.3%Mo steel (JIS SCM3) was prepared. Plasma powder build-up welding was performed on the plate-shaped steel material (base material) in the following manner. Additionally, if figure 2 As shown, the plasma powder surfacing is set to two layers and the dilution rate is changed. Dilution rate is passed as figure 2 Adjust by changing the welding speed as shown. in addition, figure 2 In the above, the first welding layer is the welding layer formed on the surface of the base material, and the second welding layer is the welding layer formed on the surface of the first welding layer. After the first welding layer is formed, the surface is ground and ground to achieve figure 2 Thickness indicated. Thereafter, after forming the second solder layer, the surface is ground and ground to achieve figure 2 Thickness indicated.

[0056] Steel preheating temperature: 300°C

[0057] Welding speed: 60~80mm / min

[0058] Auxiliary gas: Ar gas (temperature: 20°C)

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dilution factor | aaaaa | aaaaa |

| dilution factor | aaaaa | aaaaa |

| dilution factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com