Cutting device and method

A technology of cutting machine and telescopic mechanism, applied in welding/cutting auxiliary equipment, shearing device, auxiliary device, etc., can solve the problems of difficult operation, twisting together, and difficult positioning of cutting position, and achieve the effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

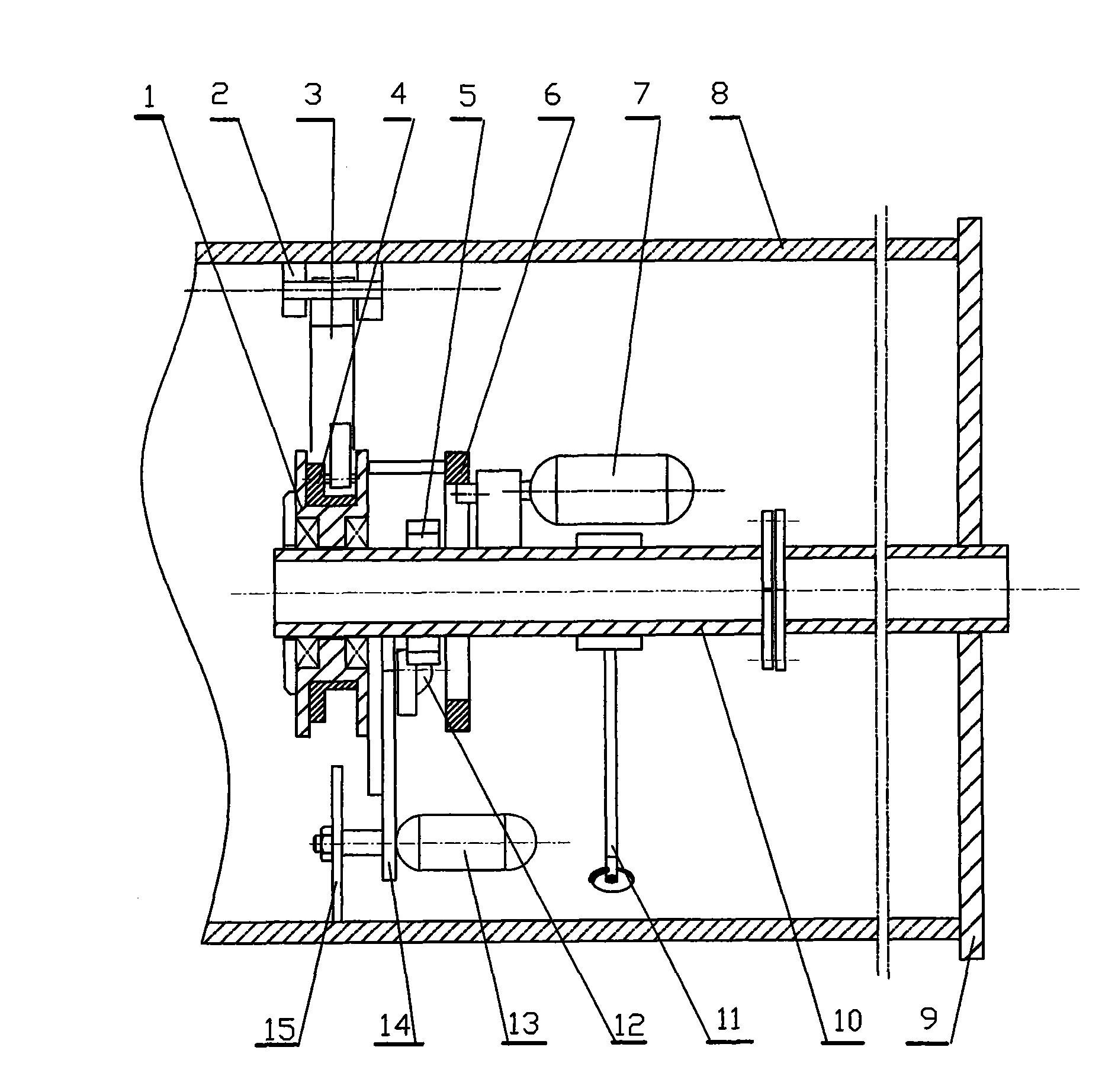

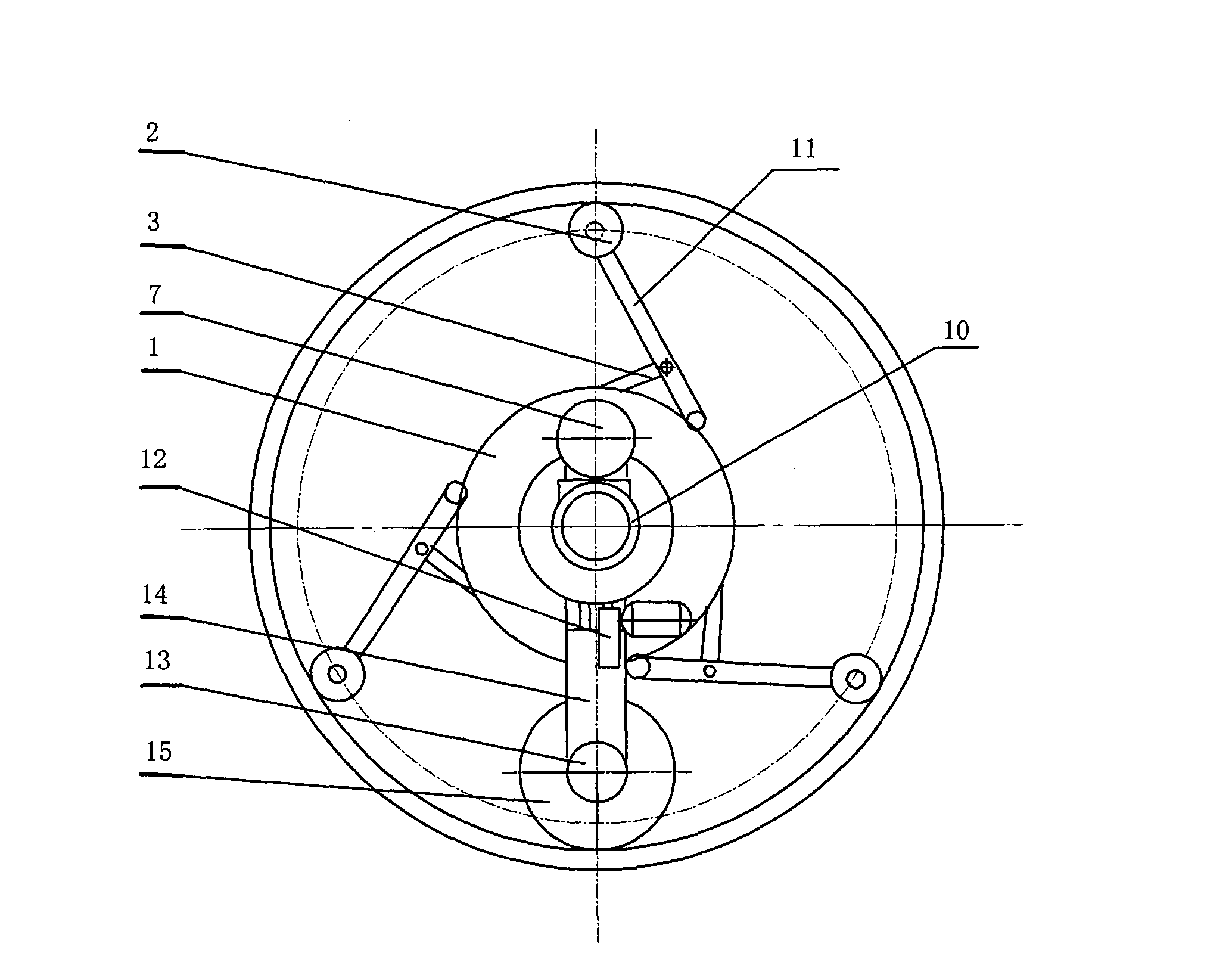

[0016] to combine figure 1 , figure 2 , the embodiment is to describe the cutting method of the cutting machine. Cutting machine is put into from cut pipe 8, is put into the position that needs cutting, and stretches into depth and is regulated by center pipe 10 and fixed plate 9. Start the positioning wheel expansion mechanism 3, the positioning wheel assembly 2 on the cutting machine is pushed out, and touches the inner wall of the steel pipe pile, so that the cutting machine is positioned in the middle of the cut pipe 8; the control motor 12 drives the telescopic mechanism 14 to push the cutting head outward , the grinding wheel sheet 15 tends towards the inner wall of the steel pipe pile, and simultaneously starts the motor on the cutting head 13 (this motor is connected with the cutting head, and the serial number is not marked), so that the grinding wheel sheet rotates at a high speed, and implements cutting from the inner wall to the outer diameter direction; start si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com