Method for producing high-surface reinforced Raman scattering active single-layer silver nanoparticle film

A technology of enhanced Raman scattering and silver nanoparticles, applied in the field of metal nanomaterials, can solve the problems of increasing the risk of high-activity SERS films, increasing the substrate preparation cycle, and increasing the film-forming time, achieving low cost, simple design, The effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

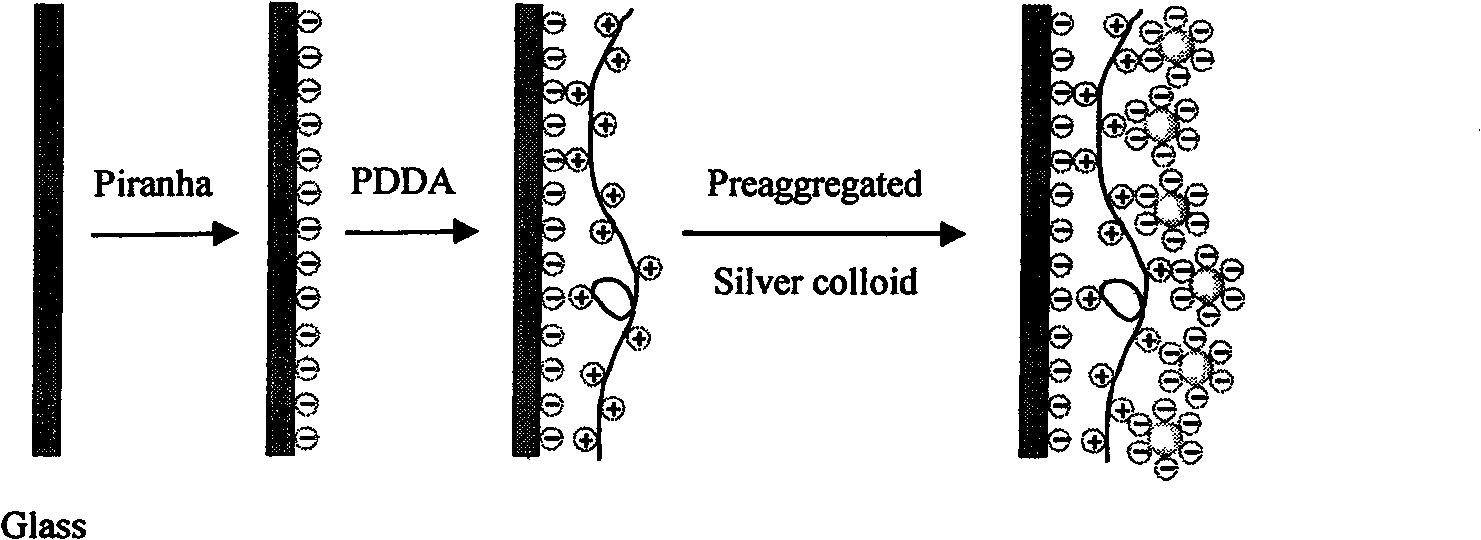

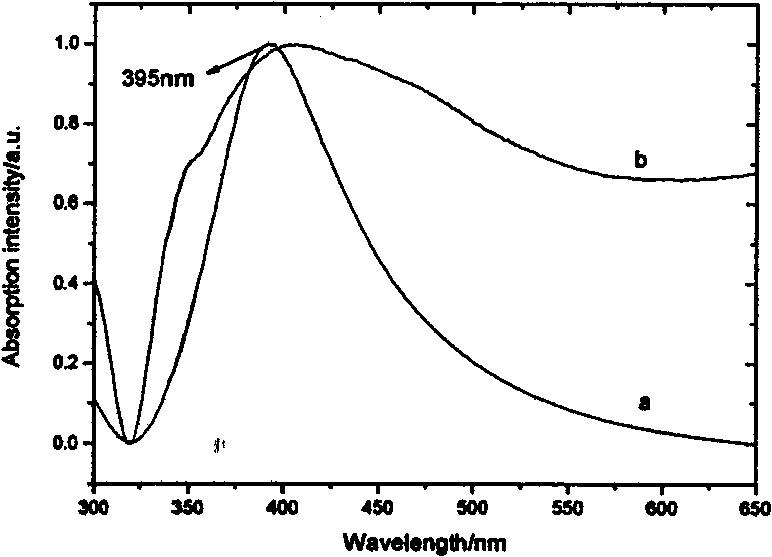

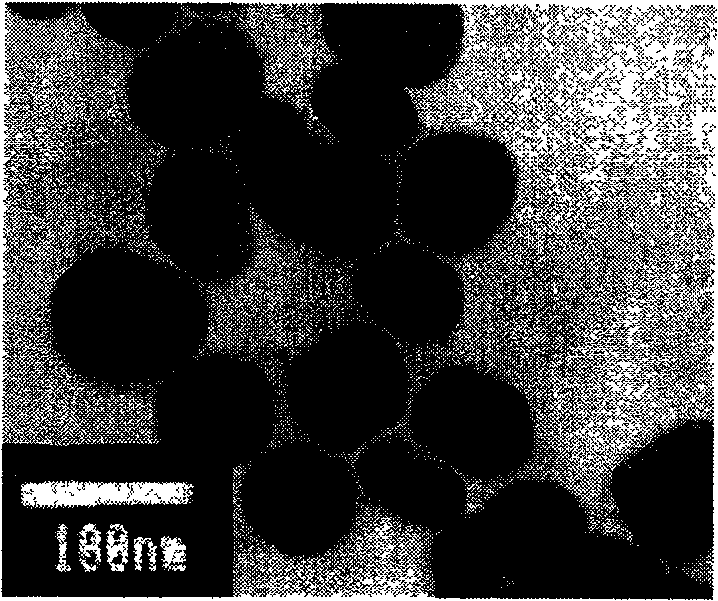

[0024] The present invention utilizes silver colloid as a raw material, first carefully cleans the glass slide as a solid carrier, then self-assembles a monolayer of poly(diallyldimethylammonium chloride), PDDA on the surface of the glass slide, and then passes Add NaCl to the silver colloid to moderately pre-aggregate raw silver nanoparticles, and finally immerse the glass slide assembled with PDDA in the above-mentioned pre-aggregated silver colloid solution, and finally self-assemble on the surface of the glass slide to form a single layer of dense silver particles, once A single-layer silver nanoparticle film with high SERS activity was successfully prepared.

[0025] The preparation method of the silver colloid solution adopts the method for preparing silver colloid by reducing silver nitrate with sodium citrate described by Lee and Meisel in J.Phys.Chem.1982,86,3391-3395.

[0026] The slides are economical and easy to obtain.

[0027] The aggregating agent NaCl has good...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com