Gasification furnace and charge-in system

A technology of feeding system and gasifier, which is applied in the direction of granular/powder fuel gasification, joint combustion mitigation, etc. Operating time, preventing instability and temperature changes, and increasing safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] While the invention will be fully described with reference to the accompanying drawings, which contain preferred embodiments of the invention, it is understood before proceeding that those skilled in the art may modify the invention described herein while obtaining the efficacy of the invention. Therefore, it should be understood that the following description is a broad disclosure for those skilled in the art, and its content is not intended to limit the present invention.

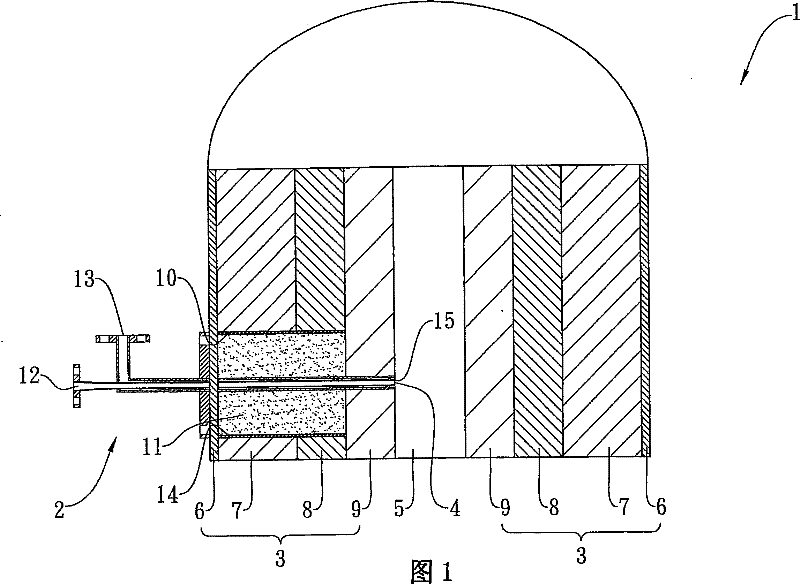

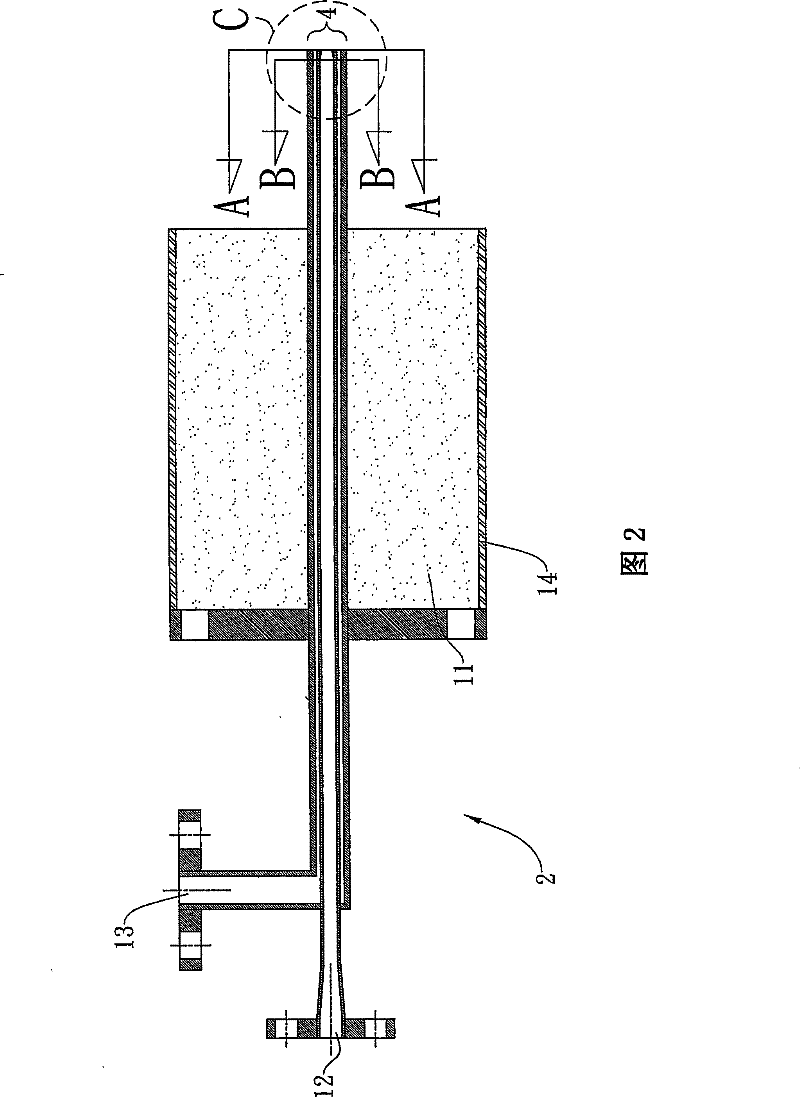

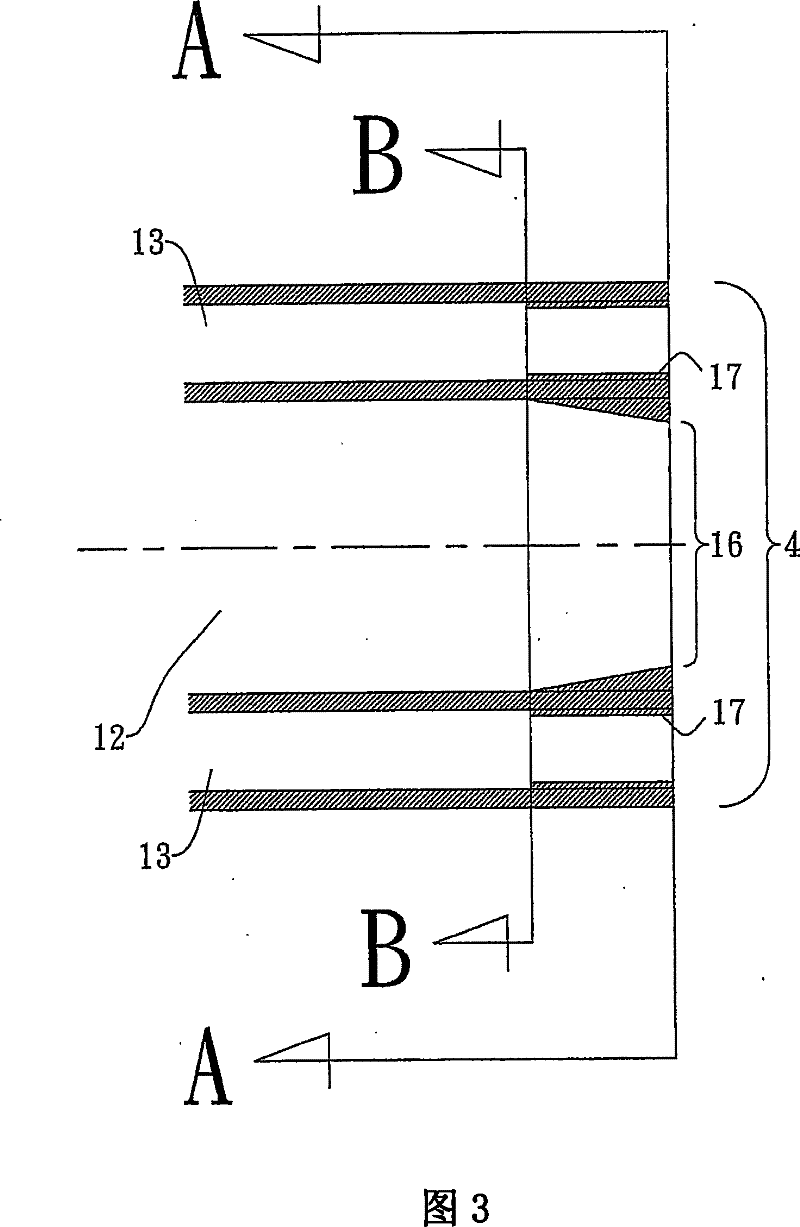

[0057] see figure 1 , shows a cross-sectional view of the first embodiment of the high-temperature gasification furnace 1 of the present invention. In this embodiment, the high-temperature gasification furnace 1 of the present invention comprises a feed burner 2 and a gasification furnace body 3, the discharge port 4 of the feed burner 2 communicates with a gasification core reaction zone 5, and the feed burner 2 The feed port (not shown) of the material burner 2 is connected to the outside of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com