Washing agent composition

A composition, detergent technology, applied in the direction of non-ionic surface active compounds, etc., to achieve the effect of foam strength, high foam hardness, and excellent foamability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

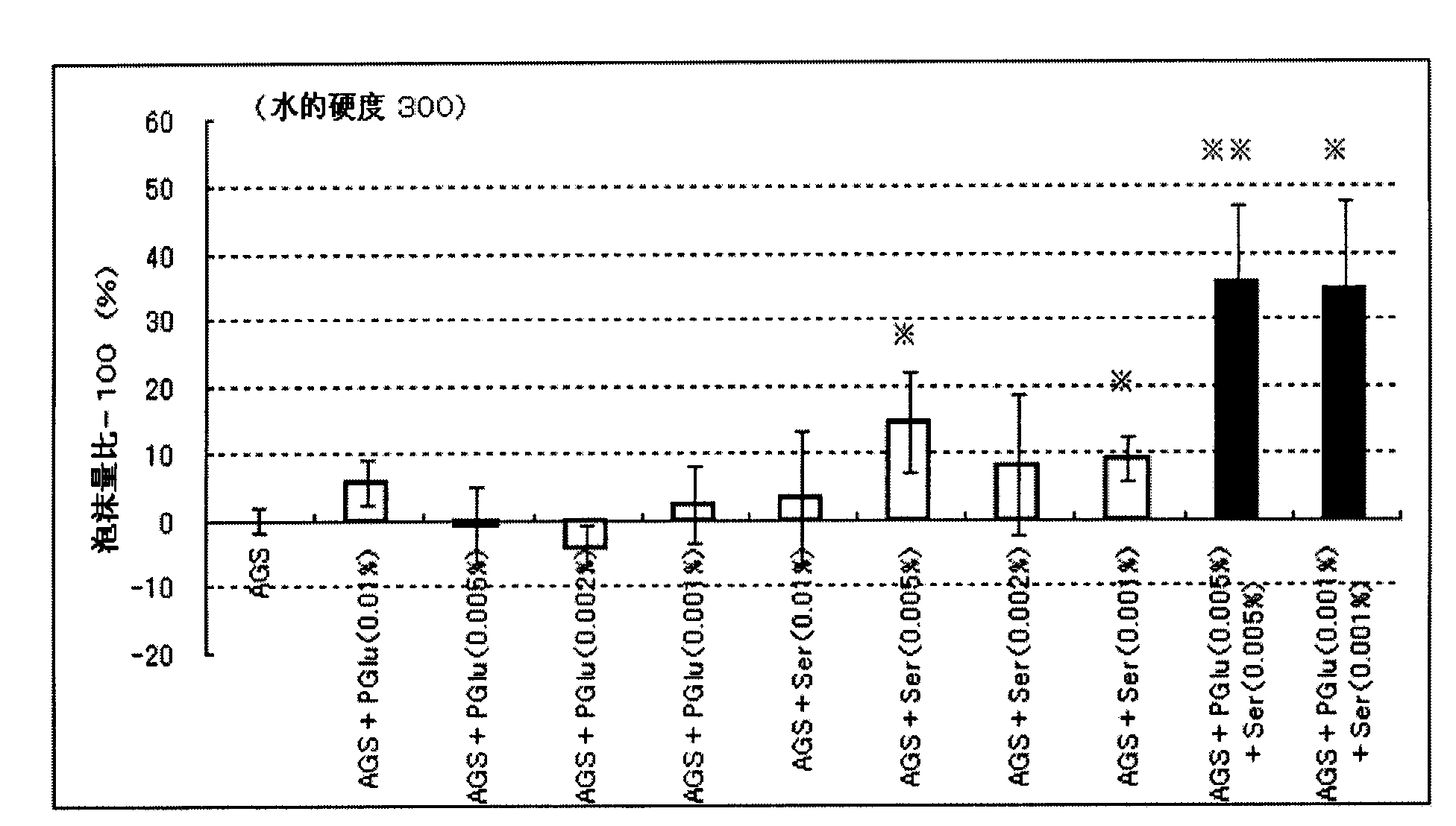

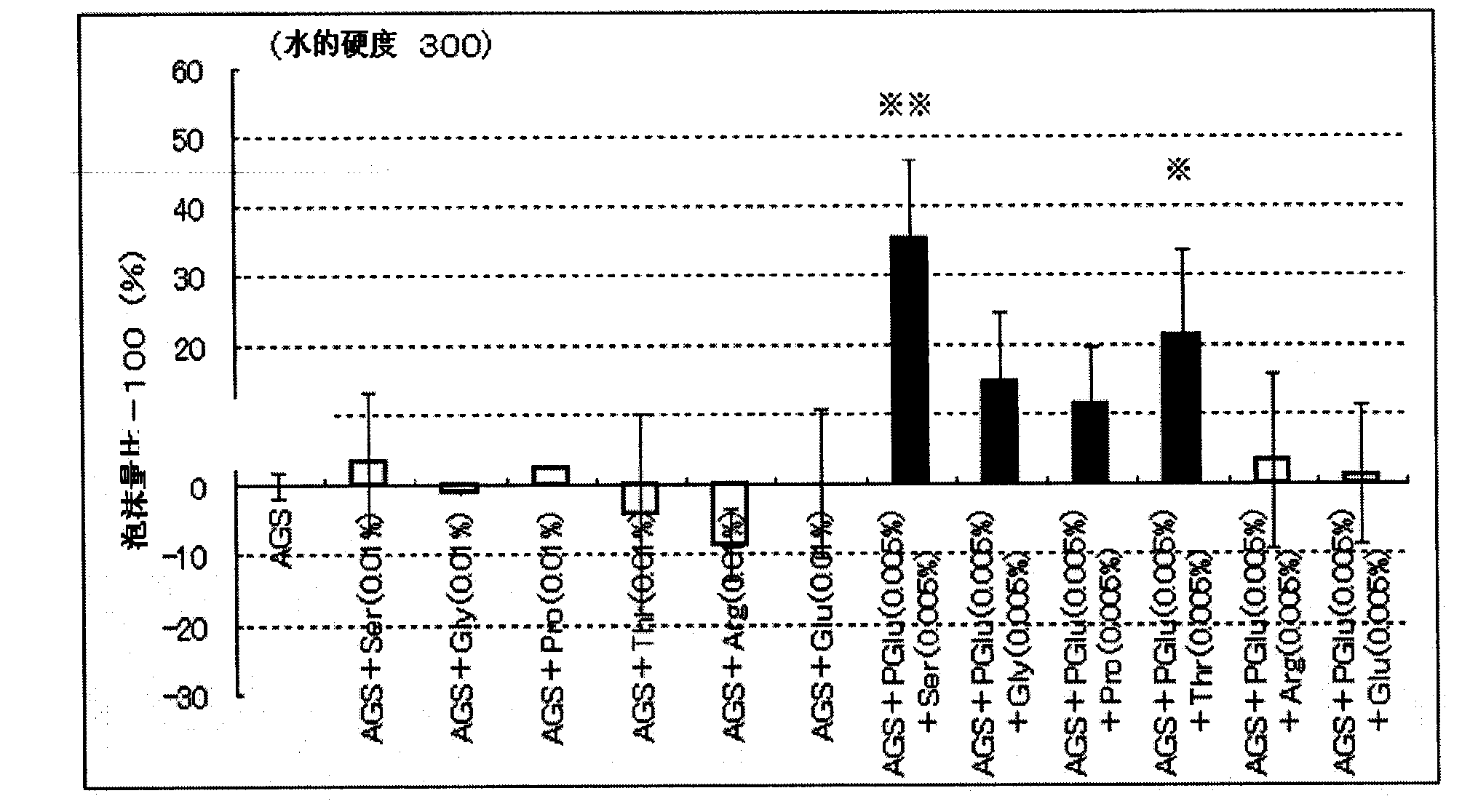

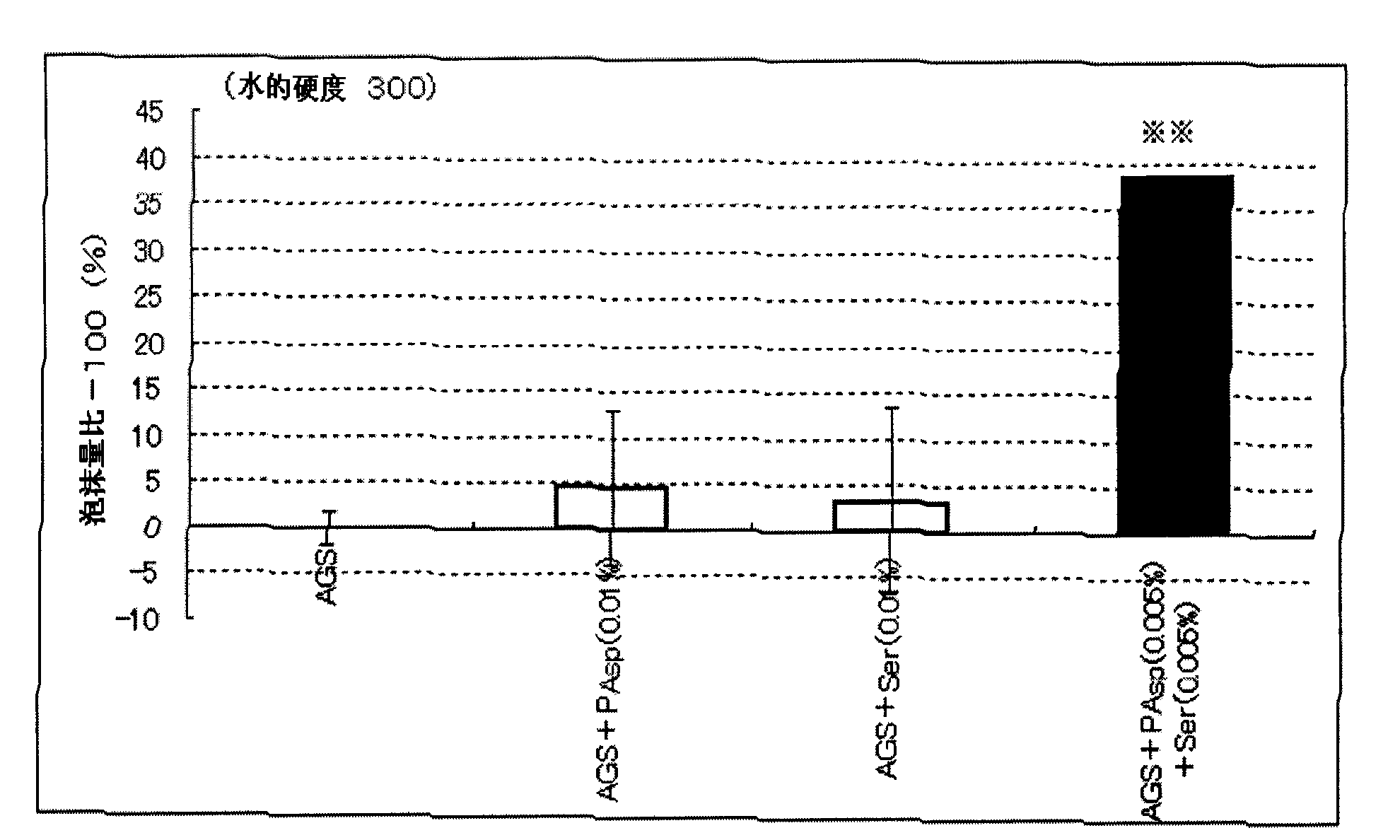

Embodiment 10

[0113] Compared with the foam hardness of Comparative Example 27, the foam hardness of Example 10 was increased by 34%, and sufficient foaming properties were achieved.

[0114] [Electron Microscope Observation of Foam]

[0115] Using the composition of Table 8, the cleansing powders of Comparative Example 28 and Example 11 were prepared.

[0116] Add water to the cleansing powder to foam by hand, put the foam mass on a stainless steel plate, and air dry for 1 day.

[0117] The air-dried foam is like Figure 8 Shown. Take out the middle part of the foam and observe it with a scanning electron microscope.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com