Process for producing methyl hydride oxidized bacteria agent

A technology for methane-oxidizing bacteria and bacterial agent is applied in the field of mixed culture of methane-oxidizing bacteria. , Easy to store and transport, Simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

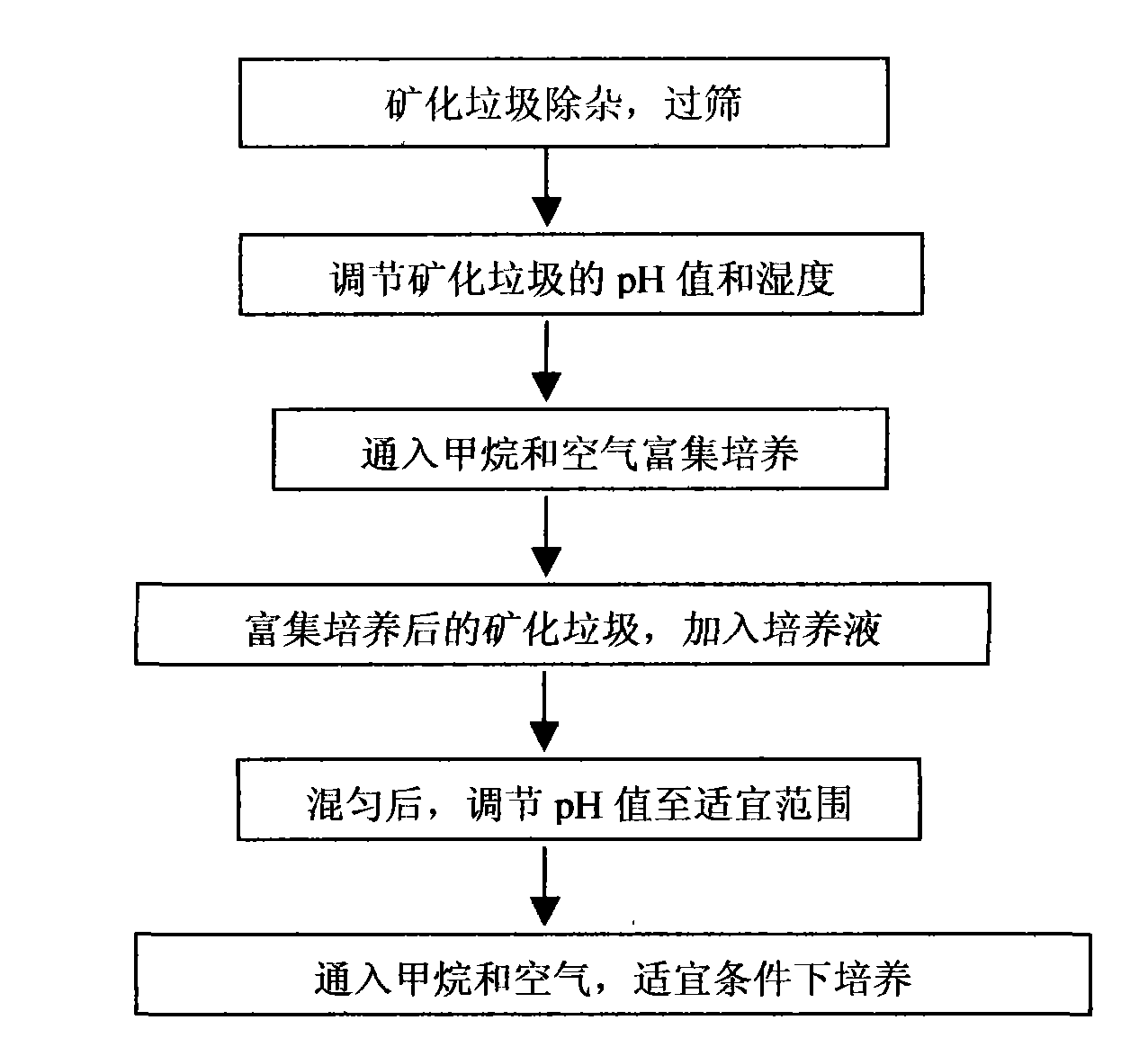

[0020] Mineralized waste was collected from Shanghai Laogang Domestic Waste Landfill. One mineralized waste was extracted from different landfill units No. 1 to No. 5 as a sample, a total of 5 samples. After sieving the mineralized waste of 5 samples to remove impurities, the pH value was adjusted to 7, and the water content was about 25%. Then put into the serum bottle and pass CH 4 and air (the volume ratio of methane and oxygen is methane: oxygen = 1:1 ~ 1:1.5), at about 30°C, carry out the enrichment culture of methanotrophic bacteria until the methane oxidation rate in the serum bottle is detected to exceed 10%. The mineralized waste with good enrichment and cultivation effect of methanotrophic bacteria was obtained, as shown in Table 1.

[0021] Table 1 Enrichment and cultivation effects of mineralized waste in different landfill units

[0022] Landfill unit initial methane volume (mL) methane volume after enrichment (mL) methane oxidation rate (%)

[0023] Unit 1 97....

Embodiment 2

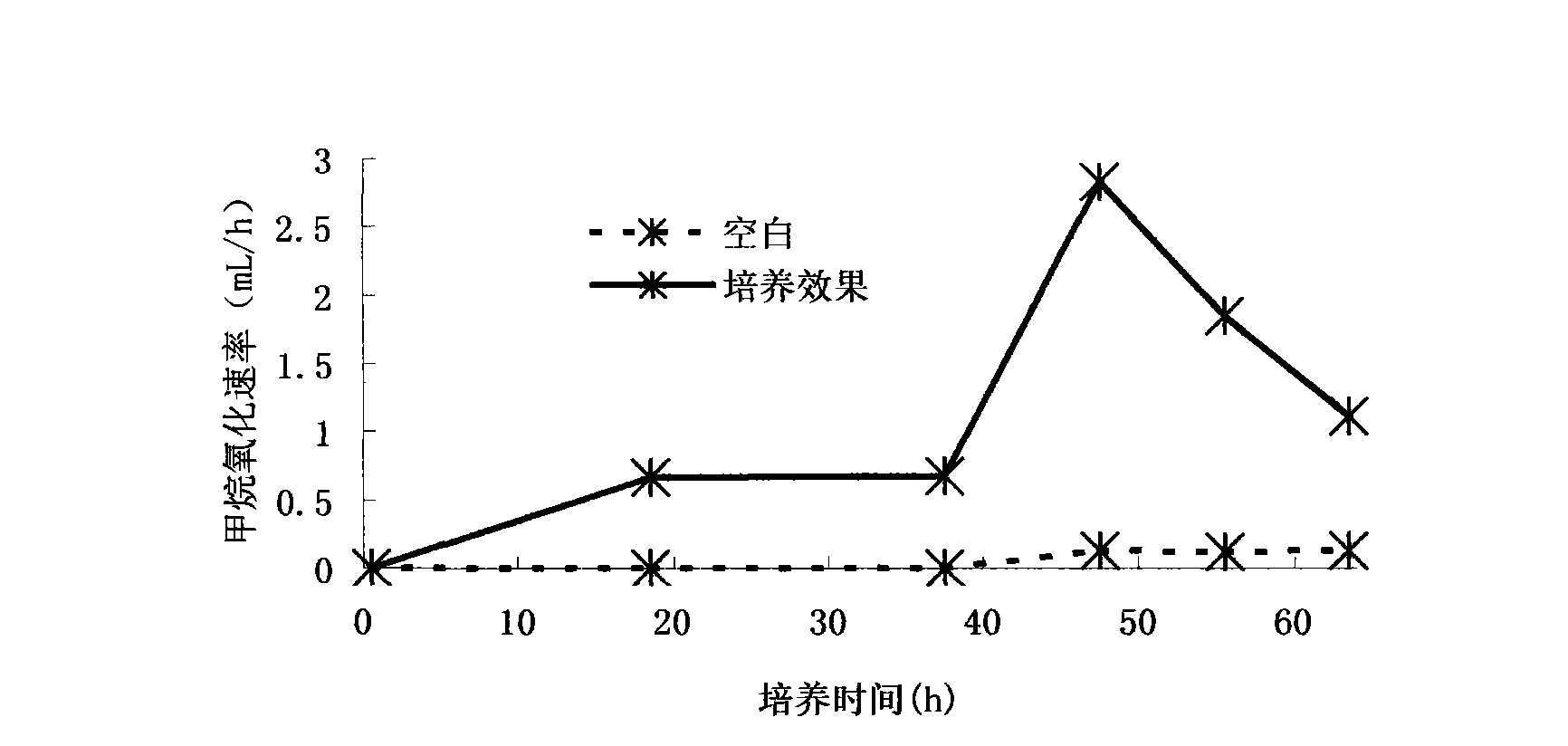

[0032] Take 0.5 g of mineralized waste from No. 1 landfill unit with the best enrichment effect in Example 1 and put it into a serum bottle, add 100 mL of improved NMS culture solution, mix, and shake on a shaker at 115-140 r / min to adjust the pH is 9, then pass into CH 4 and air (the volume ratio of methane and oxygen is methane: oxygen = 1: 1; the feed rate of the mixed gas is 130-150mL / d·100mL culture solution), and the temperature is 25-34°C for shaking bed cultivation. Regularly analyze the methane content in the serum bottle, analyze the methane oxidation amount and the change of the methane oxidation rate, if the methane oxidation rate exceeds 1.5mL / h, the methanotroph bacteria agent is prepared.

[0033] pass image 3 From the test results shown, it can be seen that the initiation of methanotroph culture is faster. Two days after the maximum methane oxidation rate appeared: the highest methane oxidation rate was 2.87mL / h, which appeared at 56h of culture.

Embodiment 3

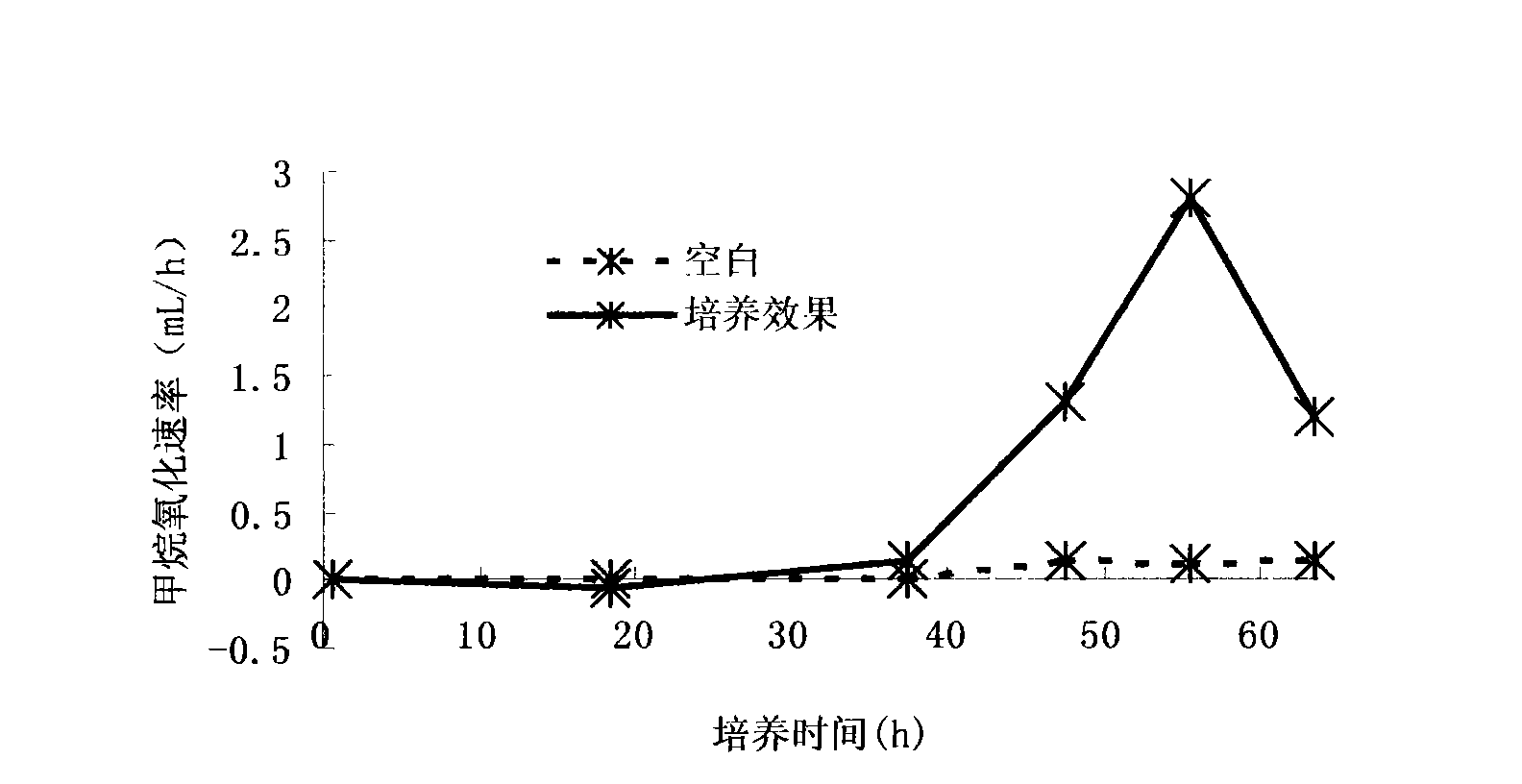

[0035] The mineralized waste from No. 1 landfill unit with the best enrichment effect was put into a serum bottle, and the improved NMS culture solution was added. The ratio of mineralized waste to culture solution was 1g:100mL. The mixed solution was shaken on a shaker to adjust the pH value, and then passed through CH 4 and air (the volume ratio of methane and oxygen is methane: oxygen = 1: 1.2; the feed rate of the mixed gas is 170-180mL / d·100mL culture solution), the temperature is 25-34°C, and the shaker is under the condition of 115-140r / min. bed culture. Regularly analyze the methane content in the serum bottle, analyze the methane oxidation amount and the change of the methane oxidation rate, if the methane oxidation rate exceeds 1.5mL / h, the methanotroph bacteria agent is prepared.

[0036] pass Figure 4 From the test results shown, it can be seen that the initiation of methanotroph culture is faster. The maximum methane oxidation rate appeared for about two days:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com