Process for producing sumach extract by using aspergillus fermentation and sumach extract produced by using the process

A technology for extracts and fermented products, which is applied in the field of preparation methods and sumac extracts prepared by this method, and can solve problems such as harsh heat treatment procedures, harmful organic solvents, and residual human bodies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

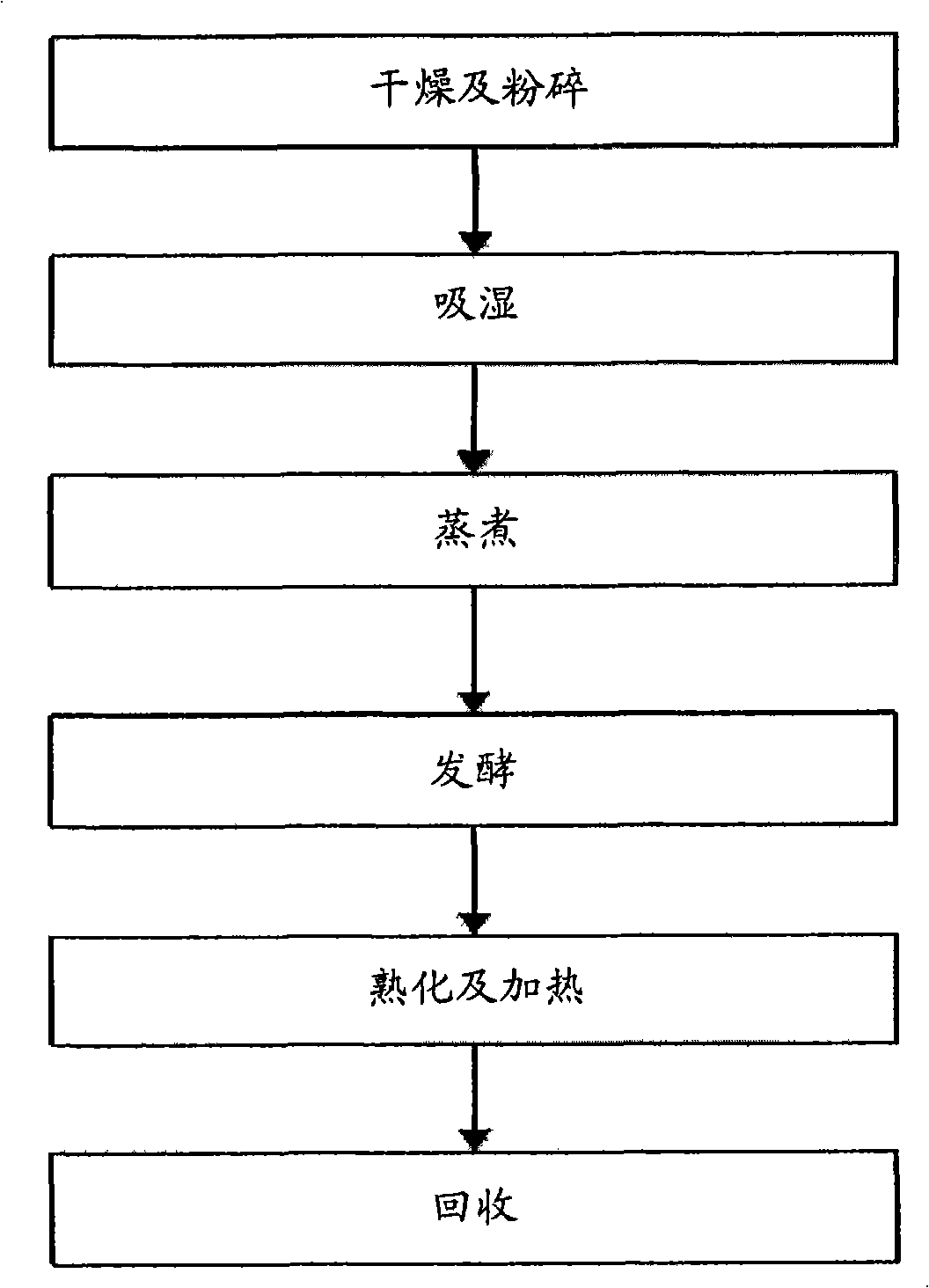

Method used

Image

Examples

Embodiment 1

[0054] Preparation of Sumac Extract Fermented by Aspergillus oryzae

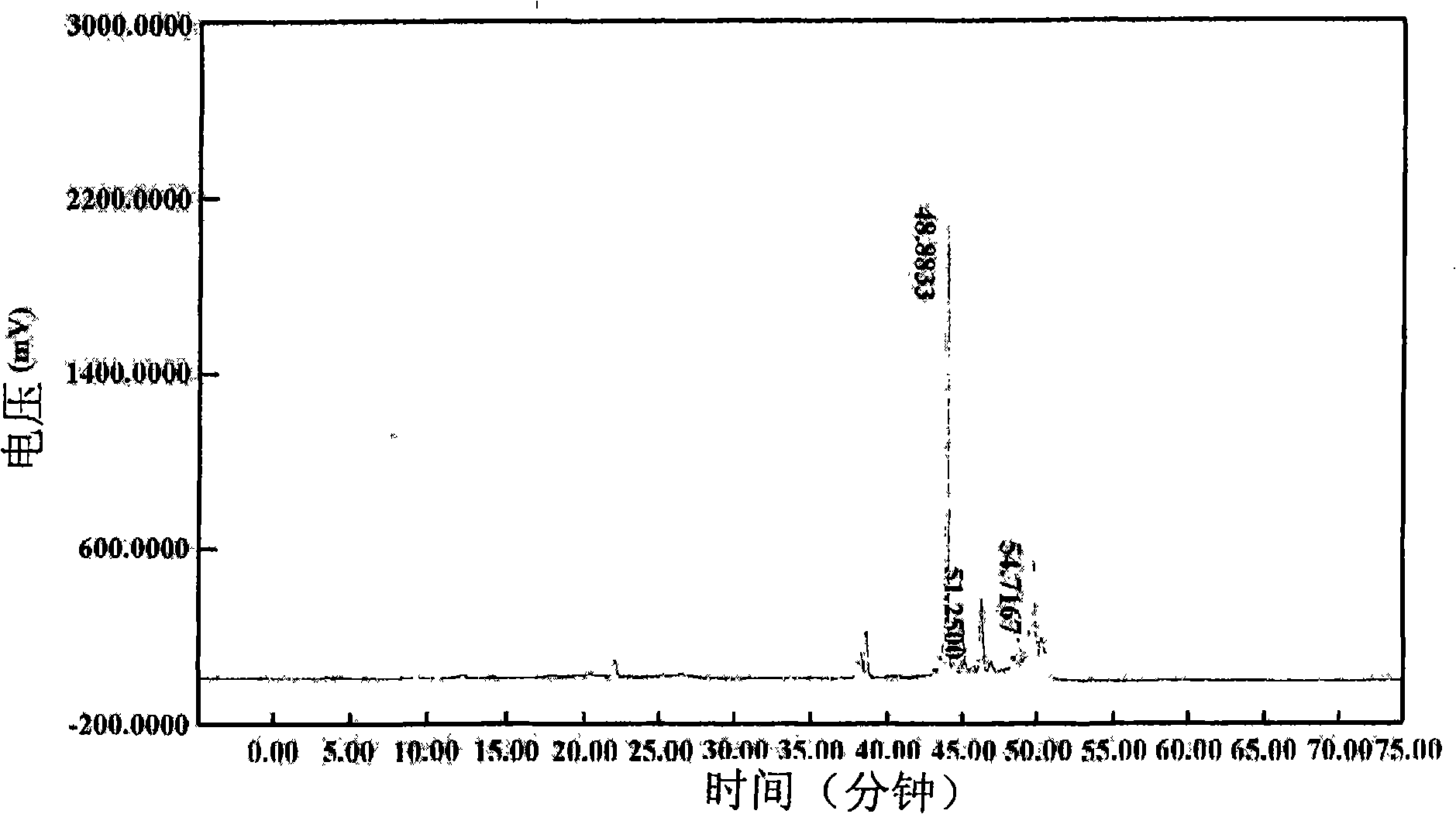

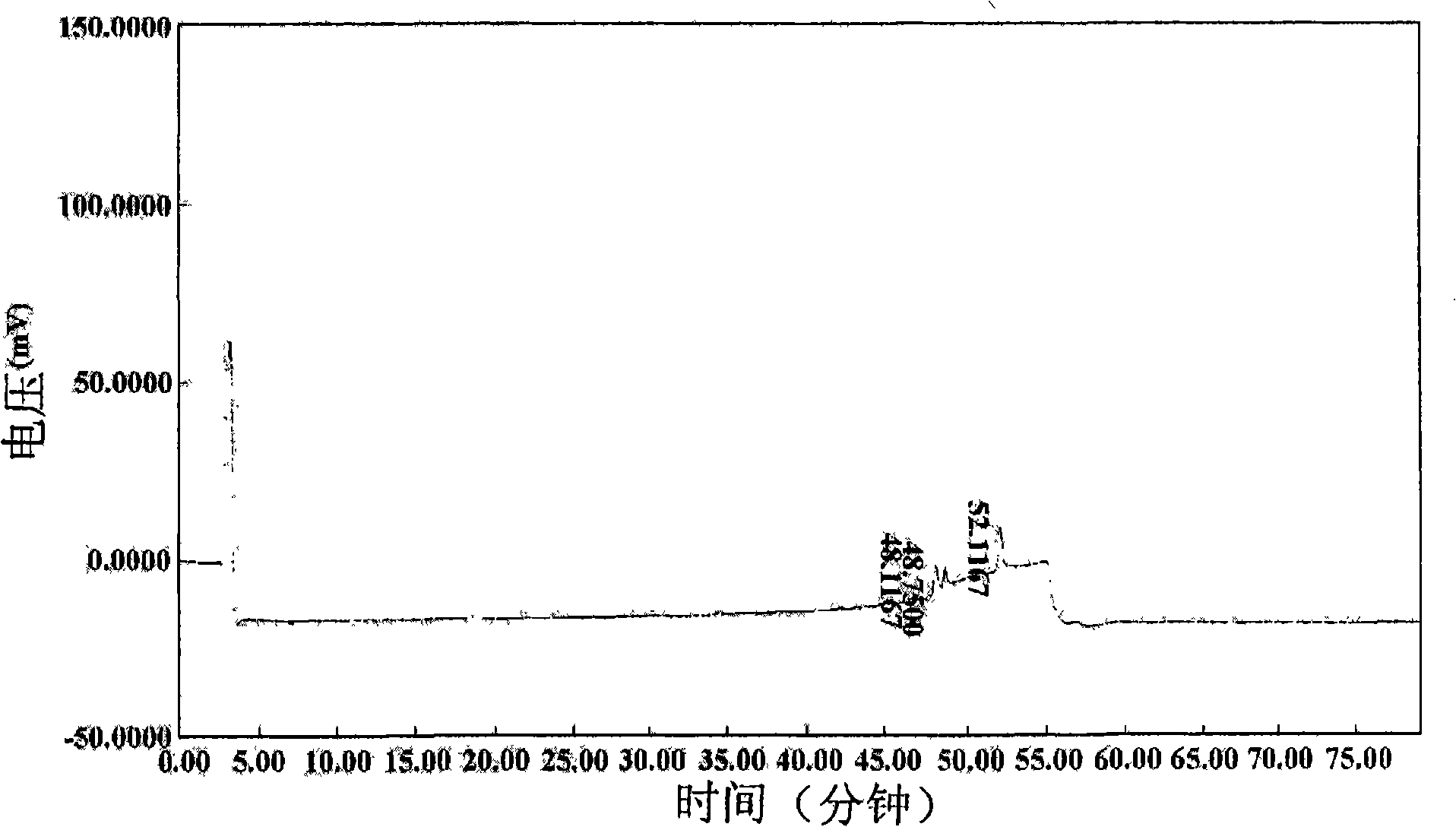

[0055] After drying the branches and stems of the lacquer tree in the shade, they were pulverized using a rod mill, and the pulverized objects of a certain size were screened out with an 8mesh sieve. Add 350g of water to 1kg of the above pulverized product to make it evenly absorbed, press it, let it stand for 1 hour, steam it in a steamer for 40 minutes, and simmer for 20 minutes. These were taken out and cooled to 35° C., and 1.5 g of Aspergillus oryzae was inoculated here, then packed in a container with a thickness of 2 cm, and fermented at 30° C. for 35 hours using an incubator. 2 L of water was added to the fermented product, aged at 55°C for 2 hours, boiled for 1 hour, and squeezed to prepare 1.5 L of sumac extract. As a result of studying the prepared sumac extract, it was found that Equivalent to 2.49% of the raw material for evaporative drying. Compared with the comparative example 1 extracted by...

Embodiment 2~4

[0057] Utilization of other Aspergillus species for the preparation of sumac extracts according to the invention

[0058] As the aspergillus in the fermentation step, except that Aspergillus oryzae is replaced by Aspergillus basilica, Aspergillus usami and aspergillus shirousamii, the sumac extracts of Examples 2 to 4 are prepared in the same way as in Example 1, and the sumac extracts prepared are extracted As a result of the analysis of the material, it was found that 2.25%, 2.32%, and 2.45% of the evaporated dry material relative to the raw material were respectively obtained. Compared with the usual extraction method (Comparative Example 1), the components were increased by 131%, 135%, and 142% or more (refer to Table 1).

Embodiment 5

[0060] Adding starch to prepare sumac extract according to the invention

[0061] When 350 g of water was added to 1 kg of the above-mentioned pulverized product, 10 g of white flour (wheat flour) was added. Other than that, the sumac extract was prepared in the same manner as in the above-mentioned Example 1, and the prepared sumac extract was processed. As a result of the analysis, it was found that 4.22% of the evaporated dry matter was obtained relative to the raw material, and compared with the usual method (Comparative Example 1), it was found that an excellent result of 245% or more was obtained (see Table 1).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com