Inlet manifold assembly

An intake manifold and assembly technology, applied in the field of auto parts, can solve the problems of large installation and layout space, large fuel leakage, and difficulty in distinguishing the external hoses of the fuel rail, so as to improve utilization rate, reduce leakage, and arrange neat effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

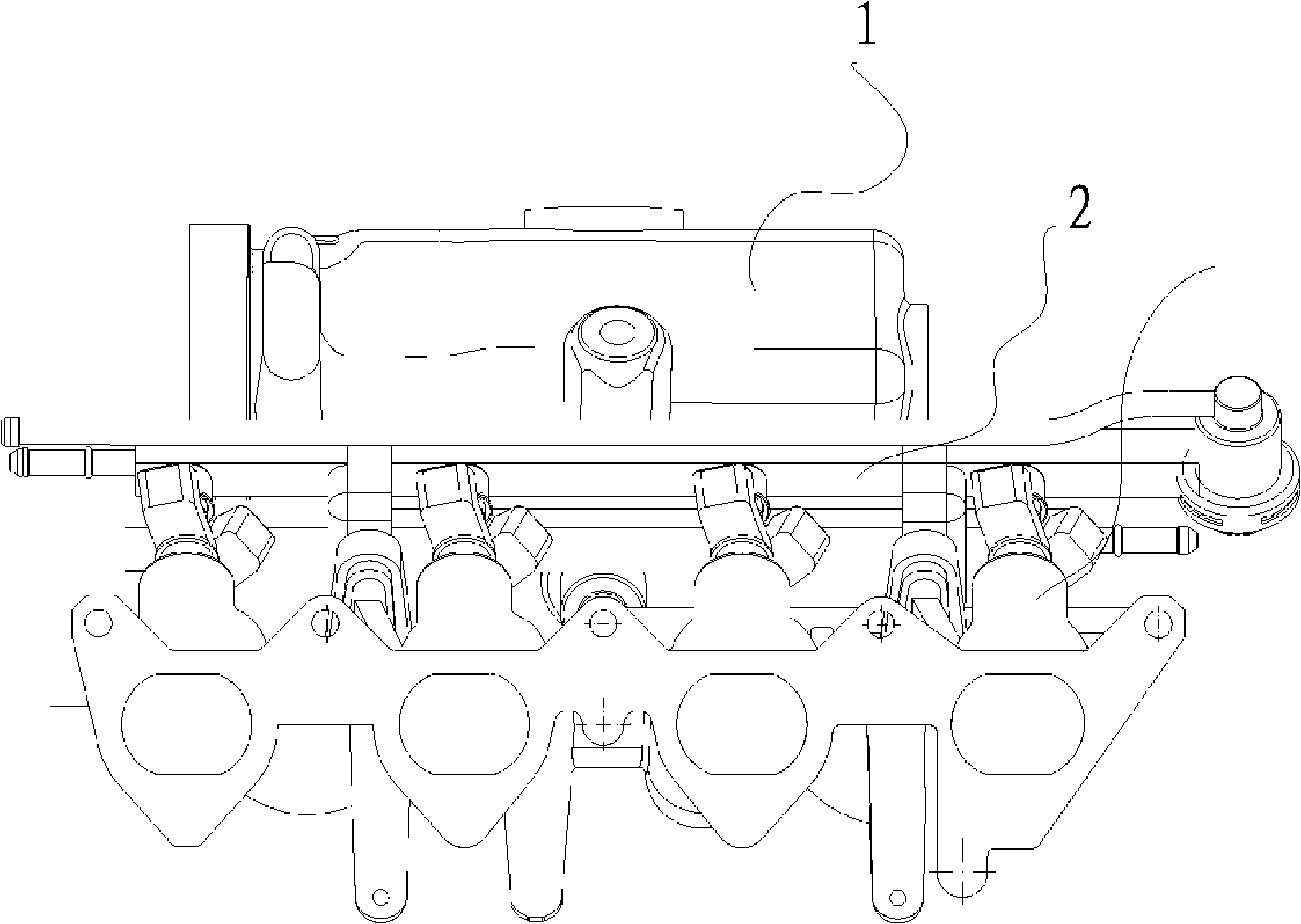

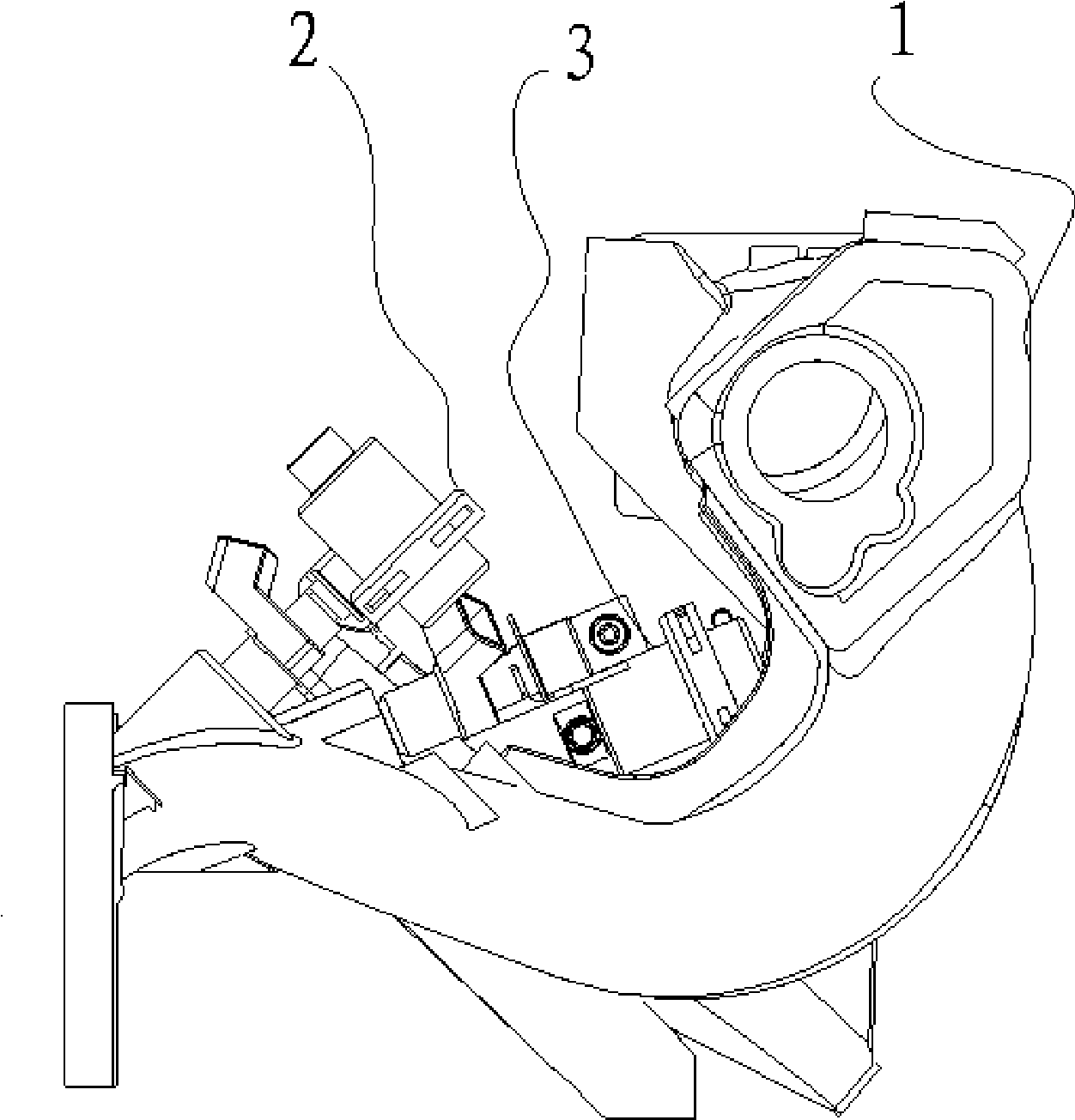

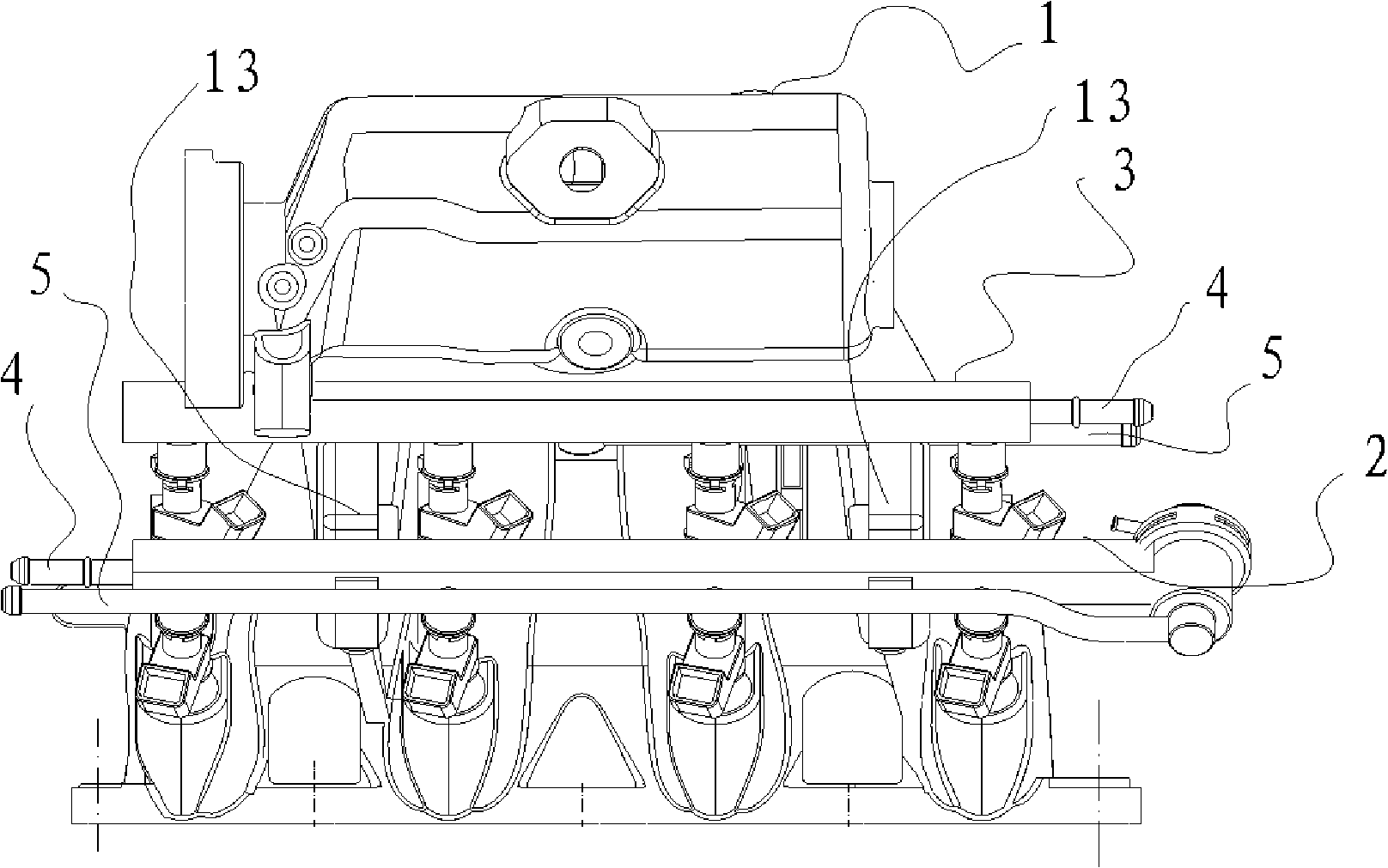

[0029] like figure 1 and 2As shown in and 3, an intake manifold assembly includes an intake manifold 1 and an oil rail assembly installed on the intake manifold 1. The intake manifold 1 is installed with two sets of oil rail assemblies arranged in front and rear. The ports of the oil inlet pipe 4 and the oil return pipe 5 on the same set of oil rail assemblies are located on the same side as the connecting ends of the external hoses. The connection ends of one set of oil rail assembly 2 and the connection ends of the second set of oil rail assembly 3 in the rear row are respectively located on both sides of the intake manifold 1 . The first set of fuel rail assembly 2 is a methanol fuel rail assembly, the second set of fuel rail assembly 3 is a gasoline fuel rail assembly, methanol is the main fuel, and gasoline is used as a start-up and backup fuel. The ports of the oil inlet pipe 4 and the oil return pipe 5 of the first oil rail assembly 2 are located on the left side of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com