Control method for multiple tail tube pulsating combustor and apparatus

A technology of pulsating combustion and control devices, which is applied in the direction of controlling combustion, lighting and heating equipment, etc. It can solve the problems that the acoustic characteristics affect the operating characteristics of the burner, and does not consider the influence of the pressure of the decoupling chamber, so as to achieve convenient adjustment and control and stable work , high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

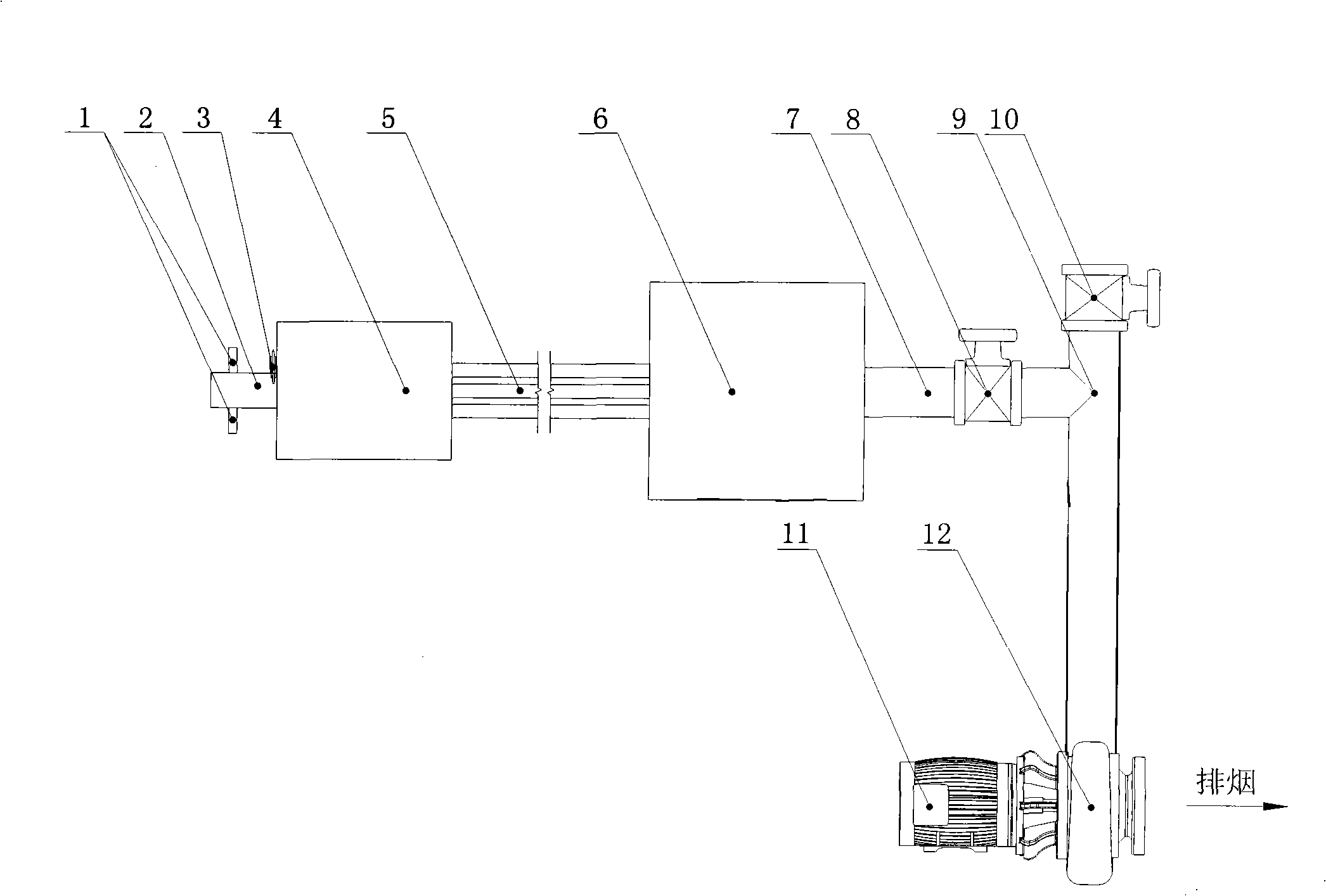

[0022] Such as figure 1 As shown, the above-mentioned multi-tail pipe pulsation burner and its control device are composed of an air supply device 1, a mixing chamber 2, an ignition device 3, a combustion chamber 4, a tail pipe 5, a decoupling chamber 6, a connecting pipe 7, and an exhaust valve 8 , Exhaust pipe 9, atmosphere valve 10, motor 11, induced draft fan 12 form. The above-mentioned tailpipe 4 adopts a multi-tailpipe structure, and the quantity and size are not limited.

[0023] Such as figure 1 As shown, the working process of the pulse burner is: gas and air enter the mixing chamber 2 through the gas supply device 1, and at the tail of the mixing chamber 2 (the side leading to the combustion chamber 4), the ignition device 3 ignites the mixed gas. Combustion raises the pressure in the combustion chamber 4 with heat release. When the pressure in the combustion chamber 4 rises to be greater than the pressure in the mixing chamber 2, the gas in the mixing chamber 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com