Semiconductor production line model building, optimizing and scheduling method based on petri net and immune arithmetic

An immune algorithm and optimal scheduling technology, applied in genetic models, calculations, control/regulation systems, etc., can solve problems such as non-timed processing, different setting times, impractical production lines, etc., to improve reusability and reduce complexity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

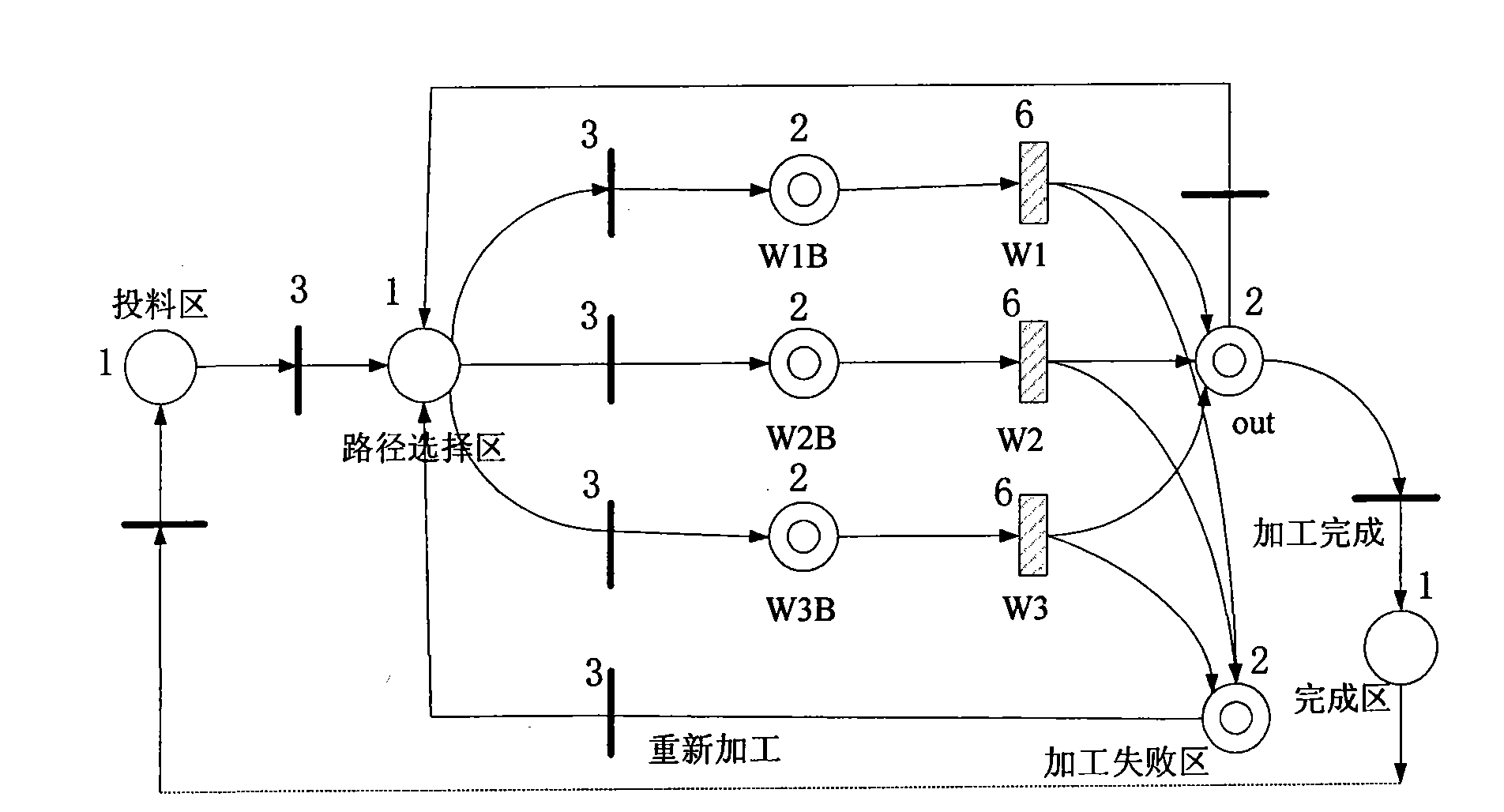

[0061] Such as image 3 As shown, according to the actual situation of the semiconductor production line, the workpiece directly enters the path selection area after passing through the "feeding area". After matching, after finding the corresponding equipment group, the workpiece is moved into the buffer of the next equipment group. After the workpiece completes a process, it is judged whether the processing is completed. If it is not completed, it will enter the path selection area again. If the processing is completed, it will enter the completion area. After the workpiece enters the completion area, the processing will stop, and there is no need to choose to go to other equipment groups. . Workpieces that fail to be processed enter the processing failure area and wait for reprocessing.

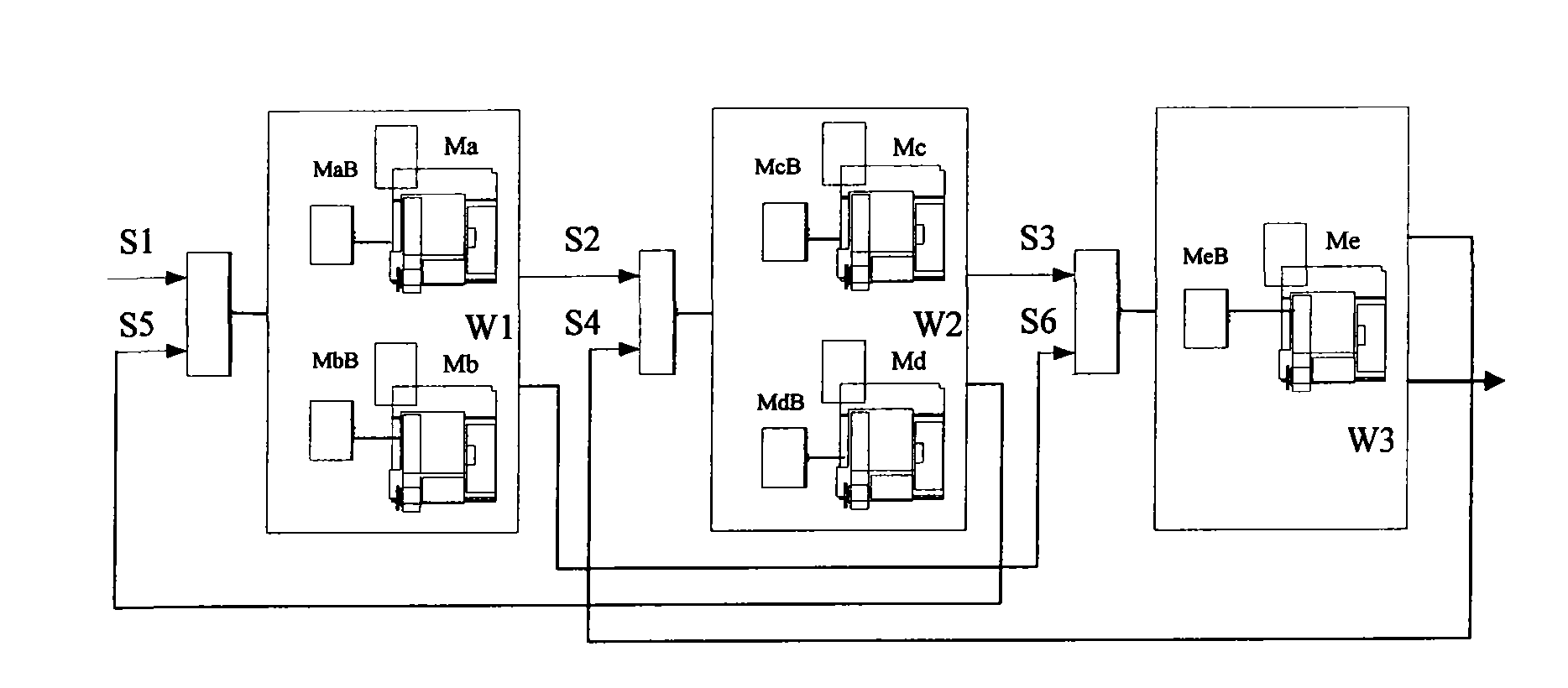

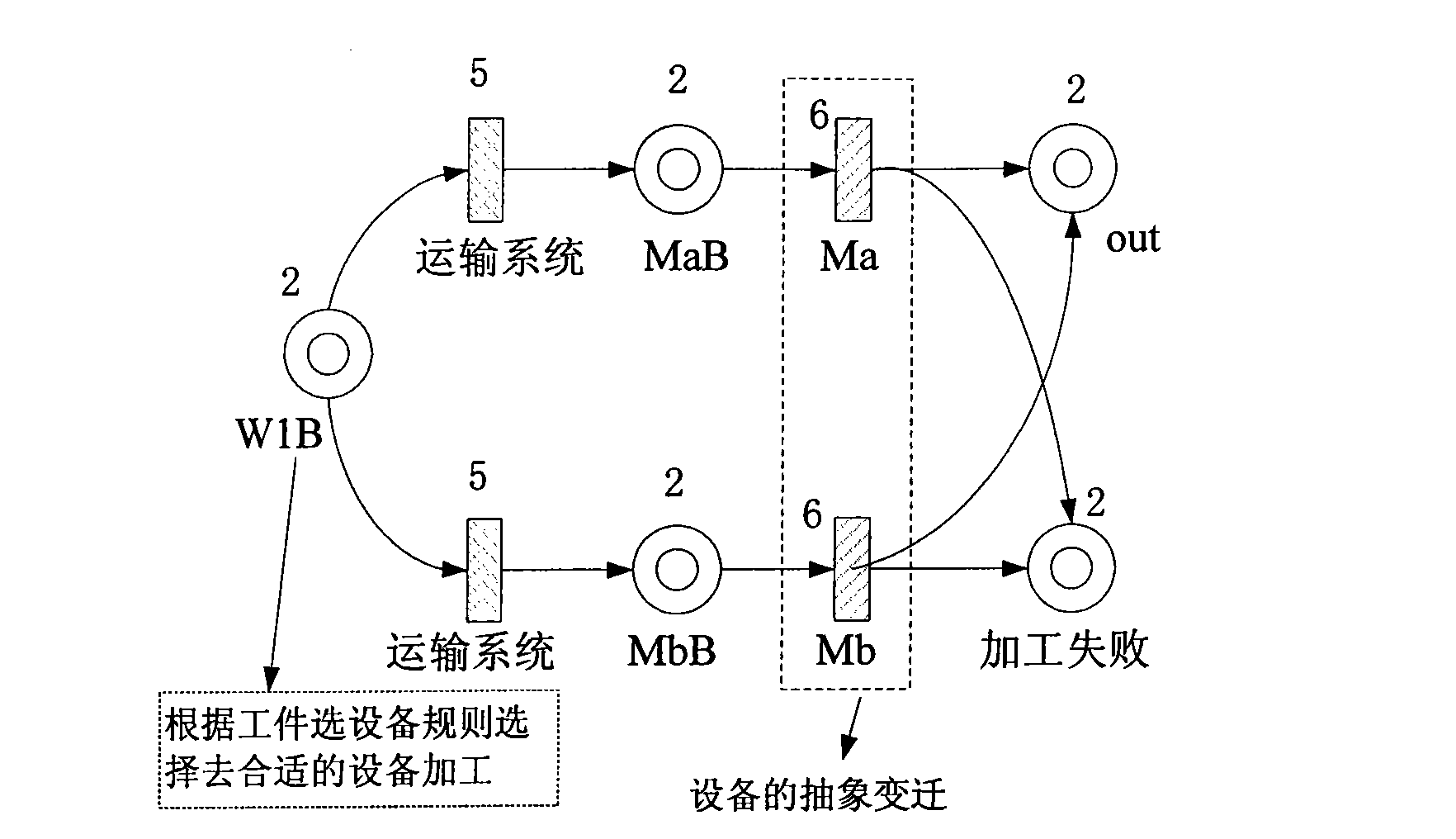

[0062] Such as Figure 4 As shown, the modeling of the equipment group takes the equipment group W1 as an example. W1 has two equipment Ma and Mb. After the workpiece enters the buffer z...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com