Near alpha medium strength titanium alloy

A titanium alloy and alloy technology, which is applied in the field of near-α type medium-strength titanium alloys, can solve the problem that the process performance of Ti-6Al-4V titanium alloy cannot meet the requirements for use, achieve good welding performance and process performance, improve process performance, Good welding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

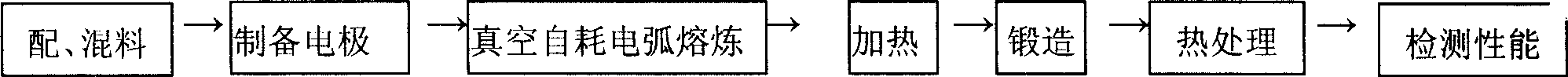

Method used

Image

Examples

Embodiment 1

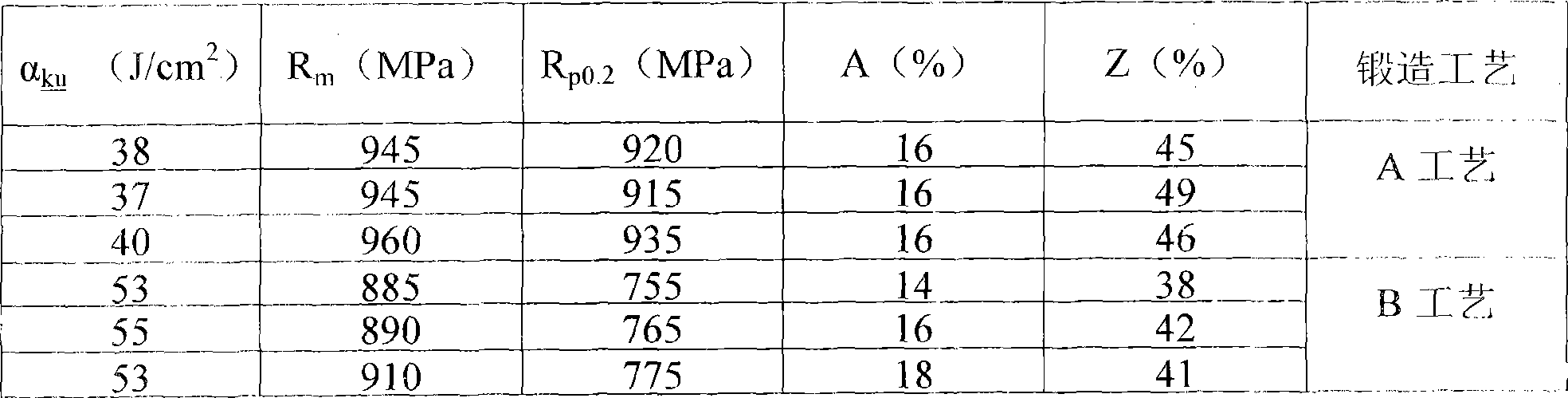

[0017] The ingredients are grouped according to weight percentage, Al: 5.5%, Mo: 1.5%, the balance is Ti and unavoidable impurities, and a Φ115mm / 20kg ingot is smelted, and the measured β transformation point is 1010-1020°C. The ingot is forged into a Φ20mm sample bar by using the above-mentioned A and B processes on the air hammer. After the sample bar is heat-treated at 870°C for 1 hour, the tensile sample is prepared according to the standard (GB / T228). According to the standard (GB / T229), impact samples were prepared and their properties were tested. The test results are shown in Table 1.

[0018] Table 1 Room temperature tensile and impact properties of Example 1

[0019]

Embodiment 2

[0021] The ingredients are formulated by weight percentage, Al: 6.0%, Mo: 2.0%, and the balance is Ti and unavoidable impurities. Melting a Φ115mm / 20kg ingot, the measured β transformation point is 1020~1030℃. The ingot is forged into a Φ20mm sample bar by the above-mentioned A and B processes on the air hammer. After the sample bar is kept at 870°C for 1 hour and air-cooled and heat-treated, the tensile sample is prepared according to the standard (GB / T228) and the standard (GB / T229) to prepare impact samples and test their performance. The test results are shown in Table 2.

[0022] The ingredients are formulated by weight percentage, Al: 6.0%, Mo: 2.0%, and the balance is Ti and unavoidable impurities.

[0023] Melting steps: batching, mixing, and pressing into consumable electrodes according to the above weight percentages, and performing two smelting in a vacuum consumable electric arc furnace, wherein the crucible specification for the first smelting is Φ80mm, the melt...

Embodiment 3

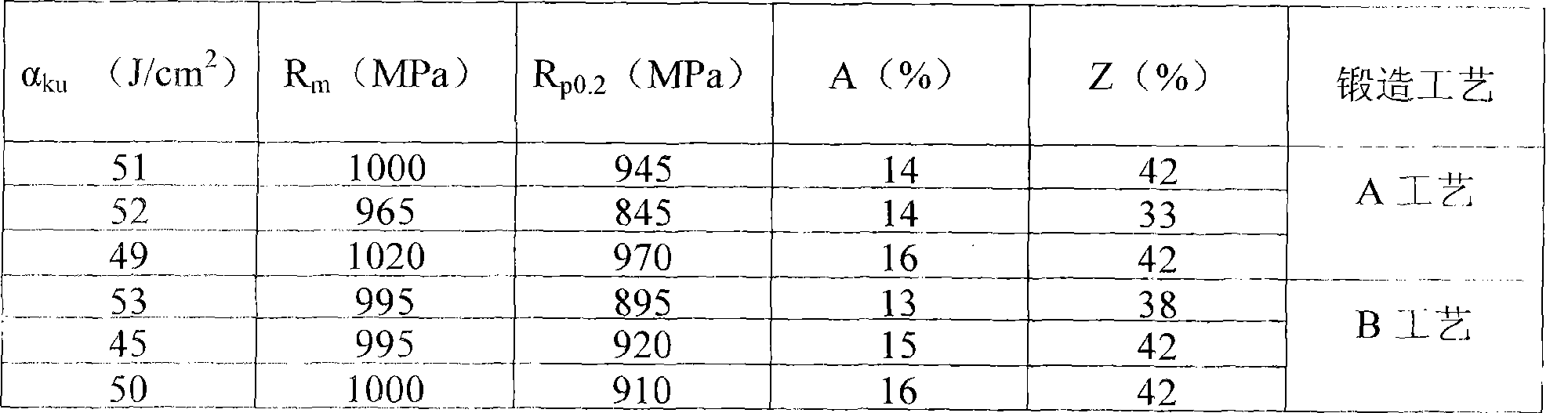

[0027] According to weight percentage, Al: 6.5%, Mo: 2.5%, the balance is Ti and unavoidable impurities, melting a Φ115mm / 20kg ingot, the measured β transformation point is 1020~1030℃. The ingot is forged into a Φ20mm sample bar by the above-mentioned A and B processes on the air hammer. After the sample bar is kept at 870°C for 1 hour and air-cooled and heat-treated, the tensile sample is prepared according to the standard (GB / T228) and the standard (GB / T229) to prepare impact samples and test their performance. The test results are shown in Table 3.

[0028] Table 3 Example 3 Room Temperature Tensile and Impact Properties

[0029]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com