Light source structure for improving light conversion efficiency by fluorescent powder

A technology of light conversion and phosphor powder, which is applied to optical elements, light sources, fluorescence and other directions used to change the spectral characteristics of emitted light, and can solve problems such as unfavorable light output purity, limiting light conversion efficiency of light source, and influence of phosphor excitation efficiency. , to achieve the effect of improving light conversion efficiency, low cost, and meeting the requirements of light purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below, the present invention is further described in conjunction with the preferred embodiments shown in the accompanying drawings.

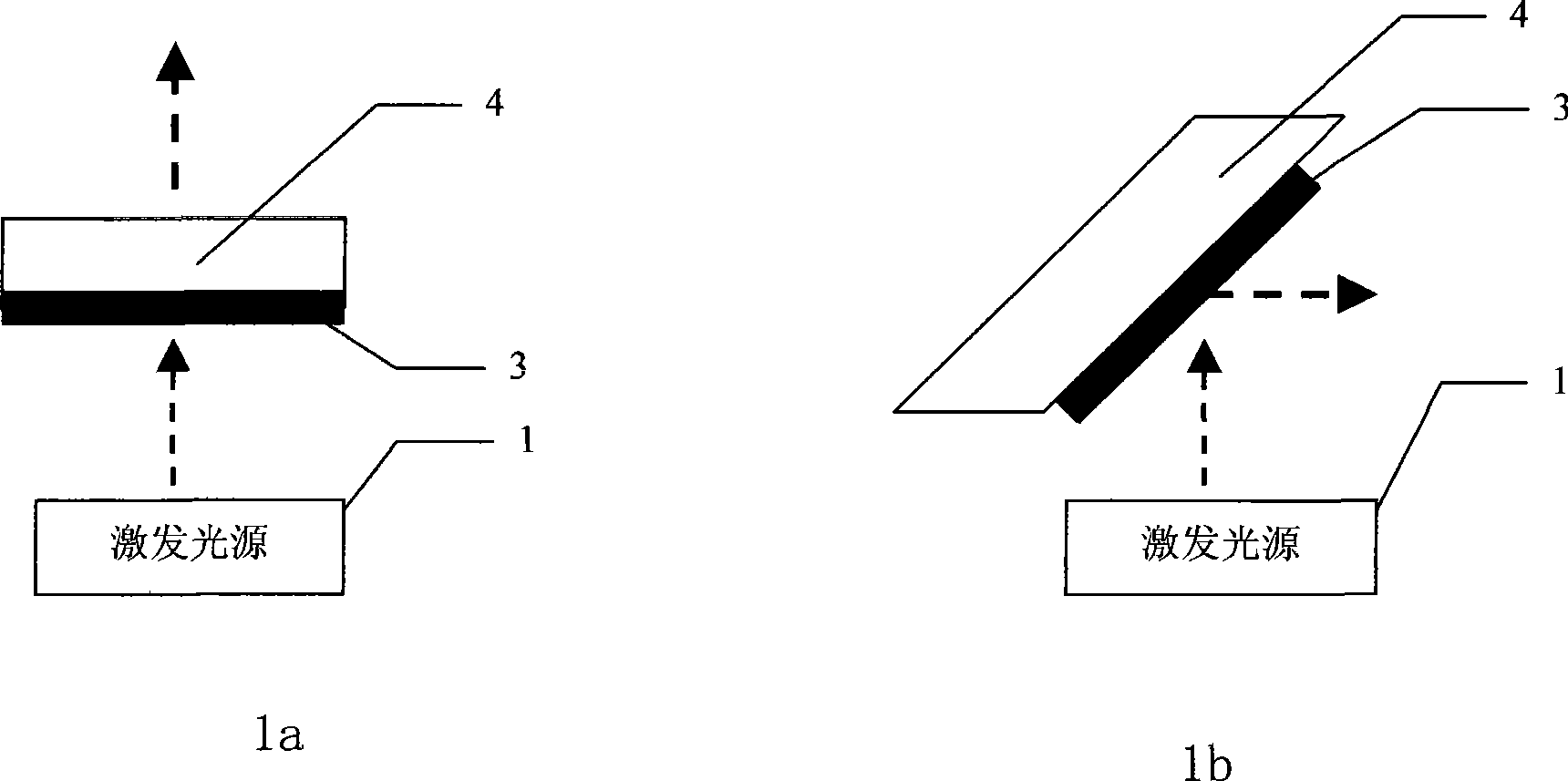

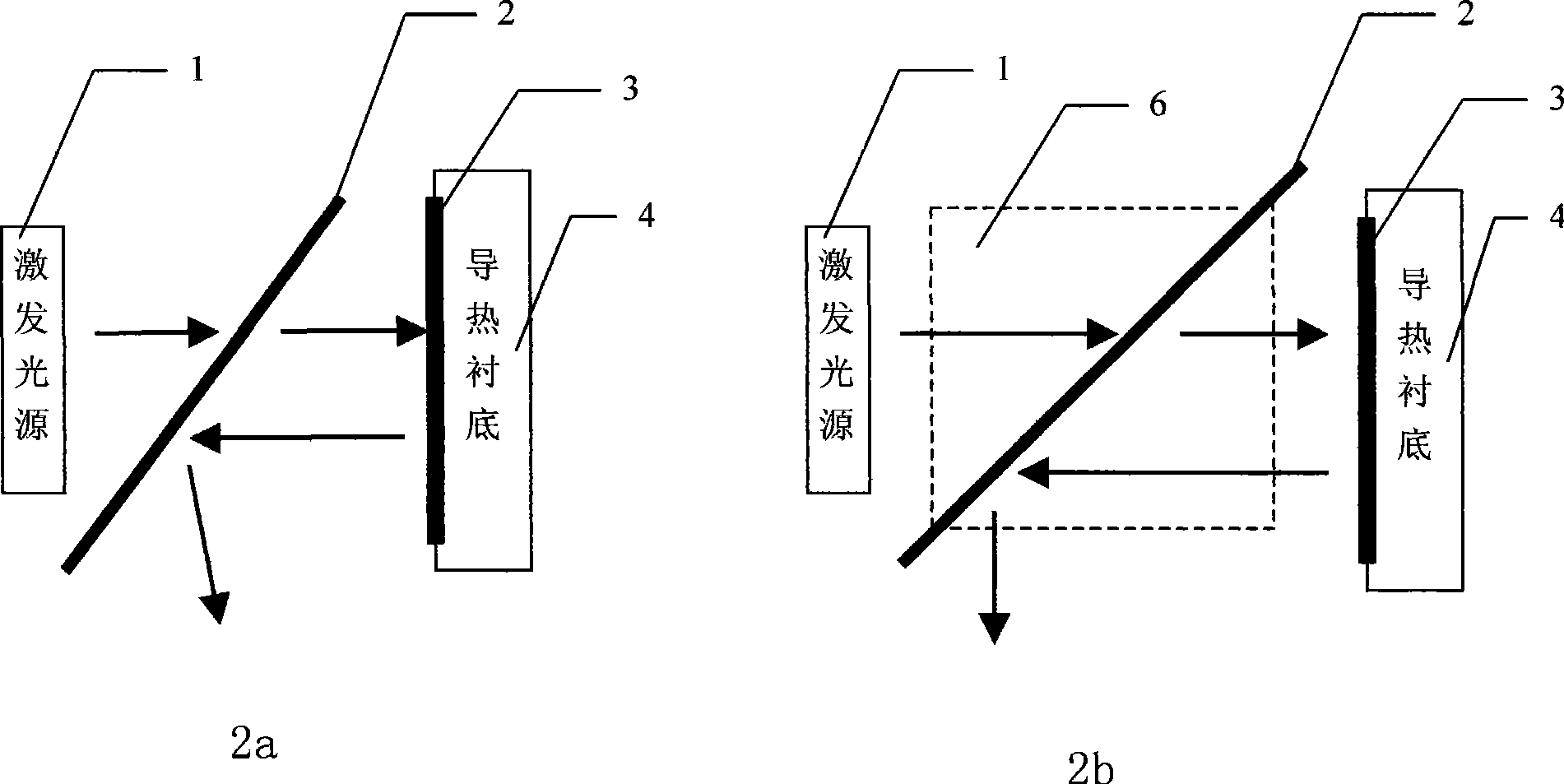

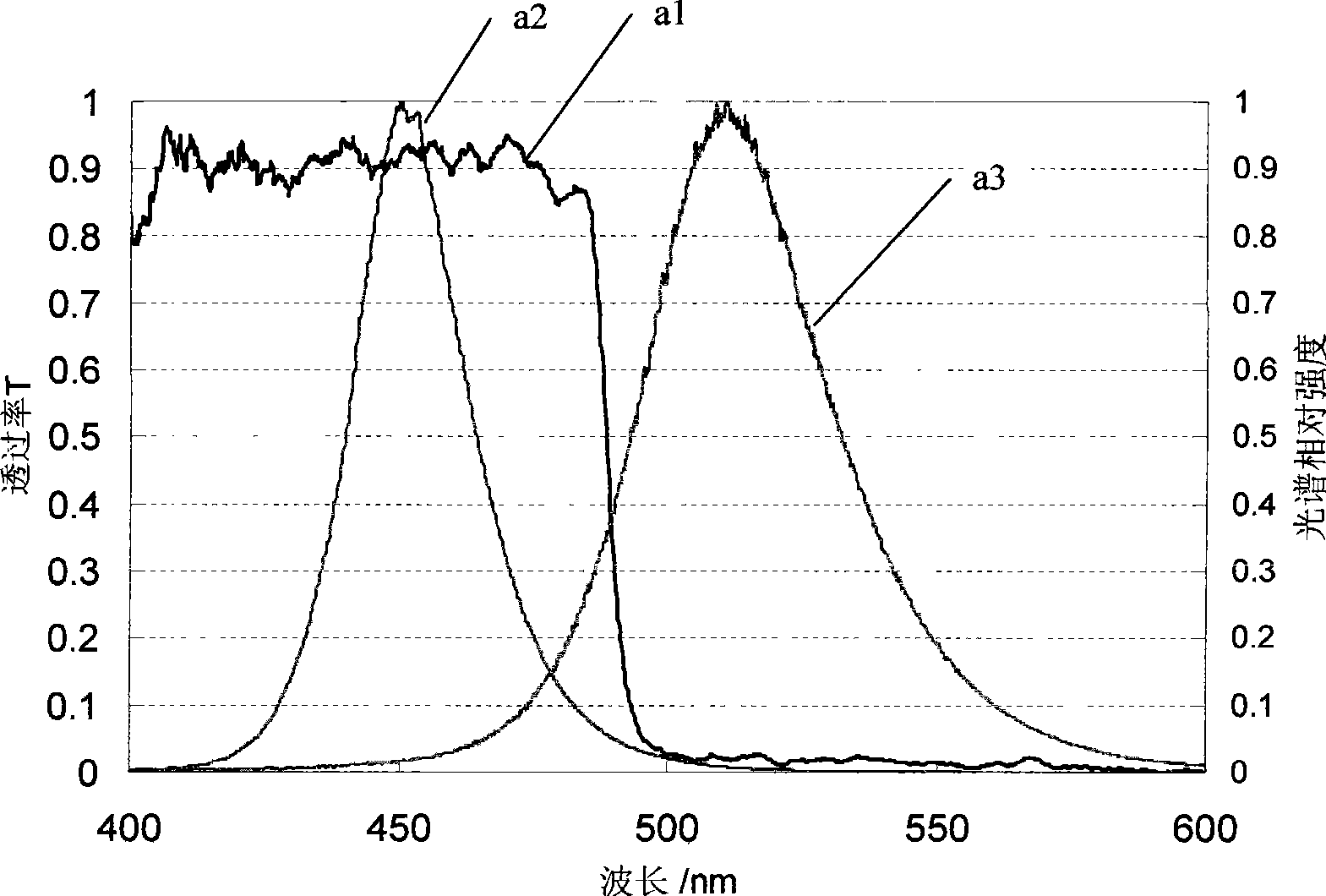

[0032] The light source of the present invention includes at least an exciting light source 1, an excited material 3, and a thermally conductive substrate 4; the excited material 3 is closely attached to the thermally conductive substrate 4, so that the accumulated heat is conducted and diffused in time. In order to make the light output directional conduction and have higher purity, the light source of the present invention also includes a spectroscopic filter 2, so that the excitation light source 1 faces the spectroscopic filter 2, so that the excitation light is obliquely directed towards the spectroscopic filter 2 , and at the same time, the excited material 3 is arranged to be roughly facing the excitation light guided by the spectral filter 2 (that is to say, the plane formed by the excited material 3 is approximately perpendicular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com