Drum-type vacuum freeze-drying machine

A vacuum freeze-drying and drum-type technology, which is applied in the direction of non-progressive dryers, dryers, and drying solid materials, can solve the problems of uneven heating of covered materials and low drying efficiency of materials, and achieve low drying costs, Fast drying and even drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Embodiments of the present invention will now be described with reference to the accompanying drawings.

[0016] A detailed structure of a drum type vacuum freeze dryer according to a preferred embodiment of the present invention will now be described in detail with reference to the accompanying drawings.

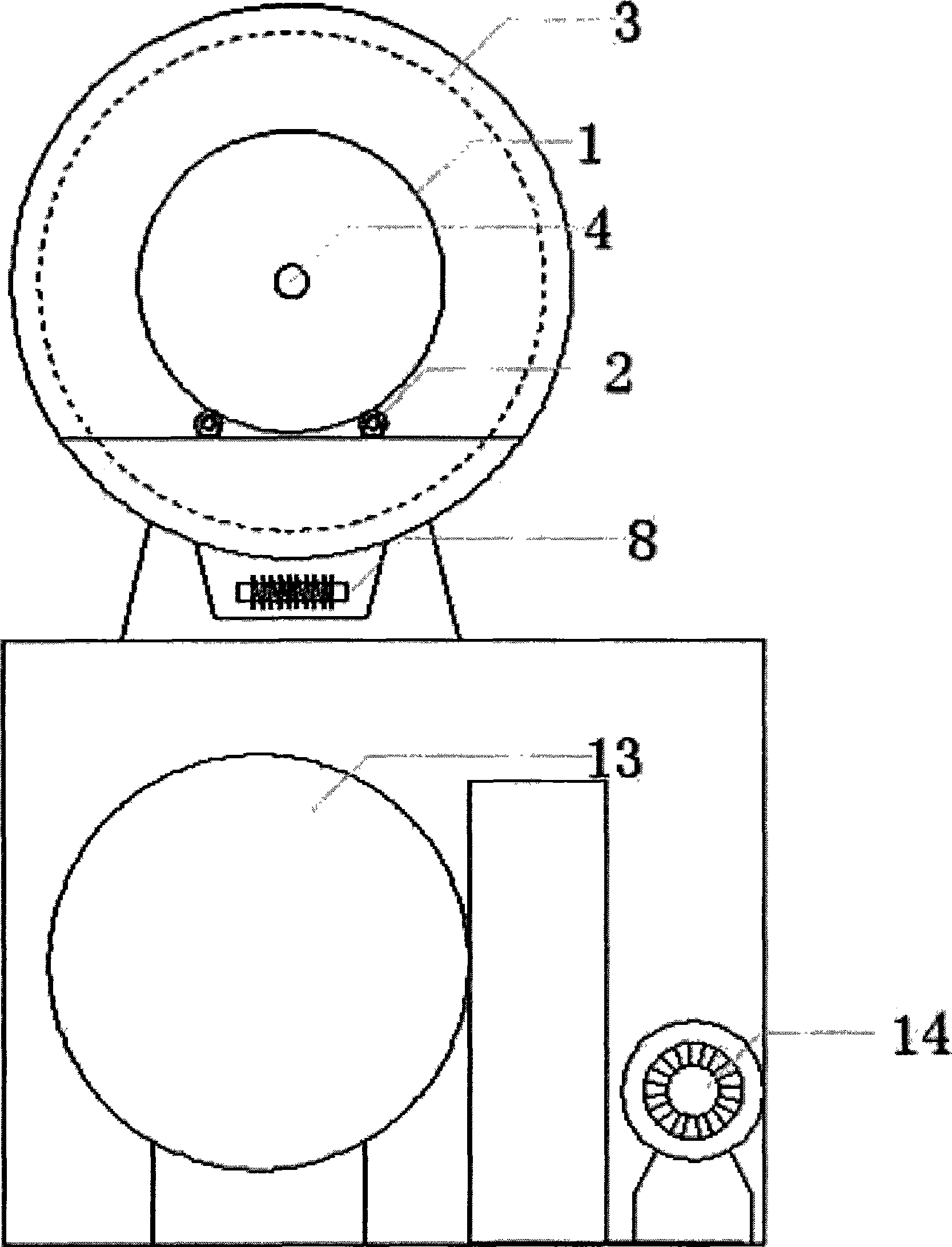

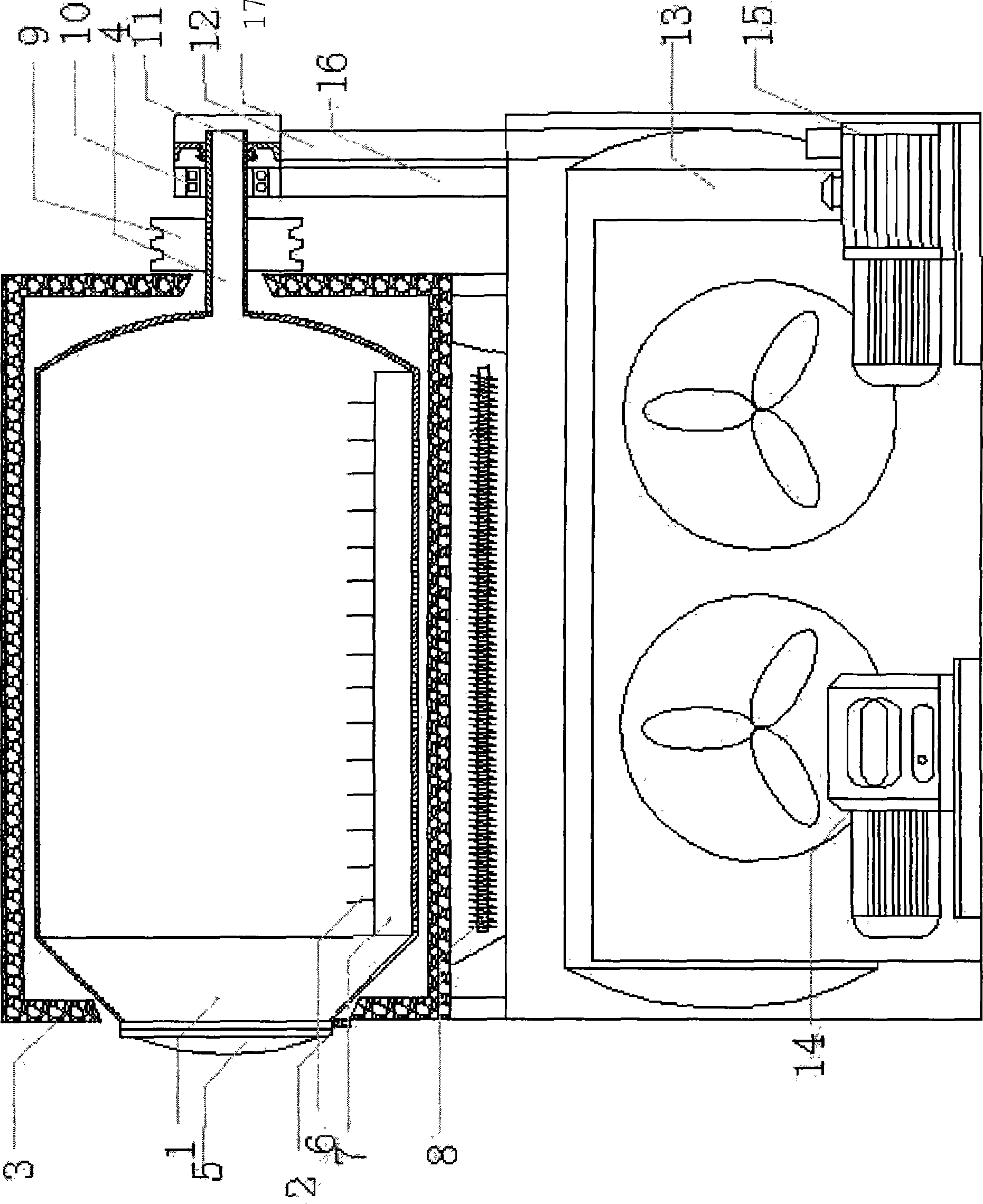

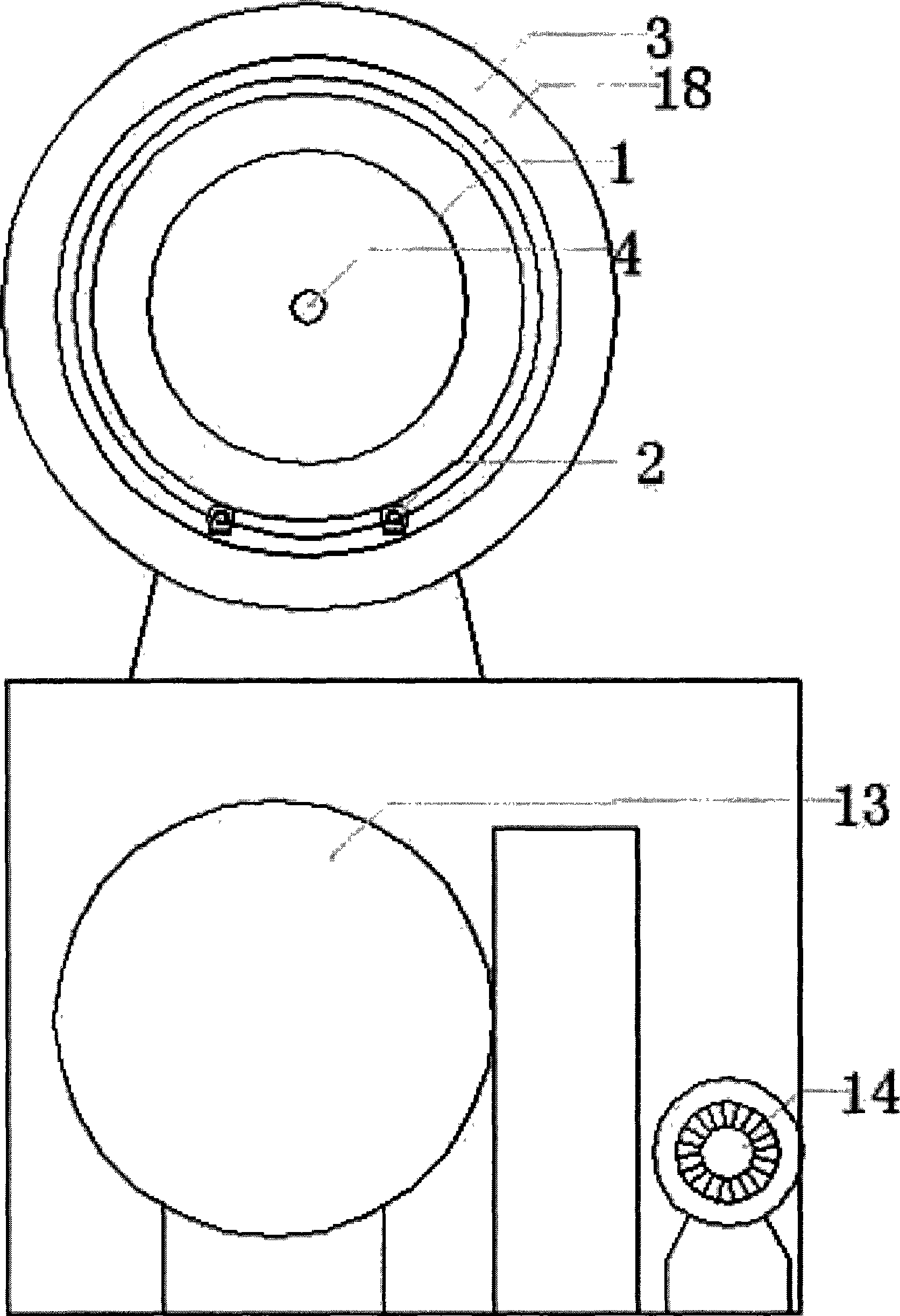

[0017] first reference figure 1 , figure 2 , which shows a drum-type vacuum freeze dryer according to a first preferred embodiment of the present invention. As shown in the figure, the drum-type vacuum freeze dryer according to this preferred embodiment has a rotatable circular drying cylinder 1, and the outer periphery of the drying cylinder 1 is wrapped with a thermal insulation layer 3 that is not in contact with the drying cylinder 1, so One end surface of the drying cylinder 1 is provided with a drying cylinder transmission shaft 4 for rotating the drying cylinder 1 , and a sealing door 5 is provided on the other end surface. In addition, one end of the dryi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com