Method for processing straight-shaped vertical tube of motorcycle

A processing method and motorcycle technology, applied to bicycle accessories, steering mechanisms, transportation and packaging, etc., to achieve the effects of reduced production costs, simple equipment, and small investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

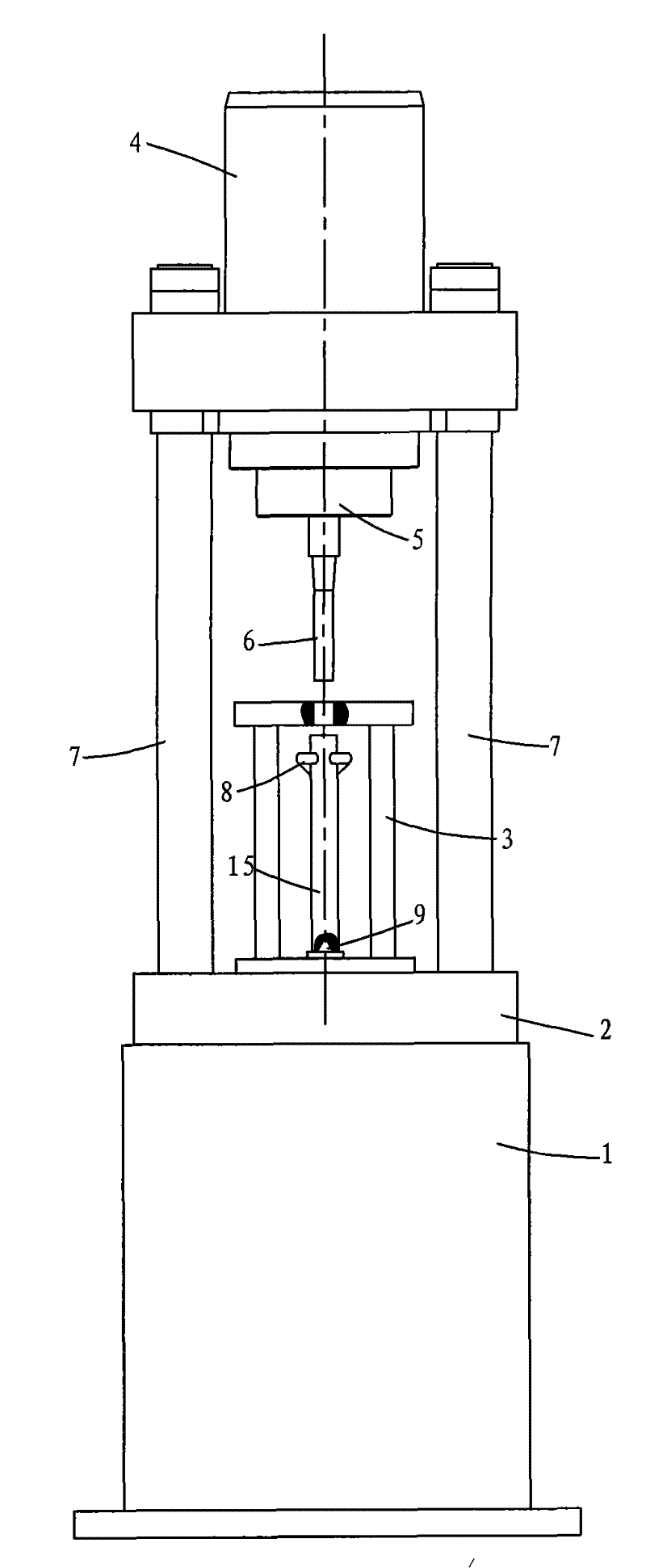

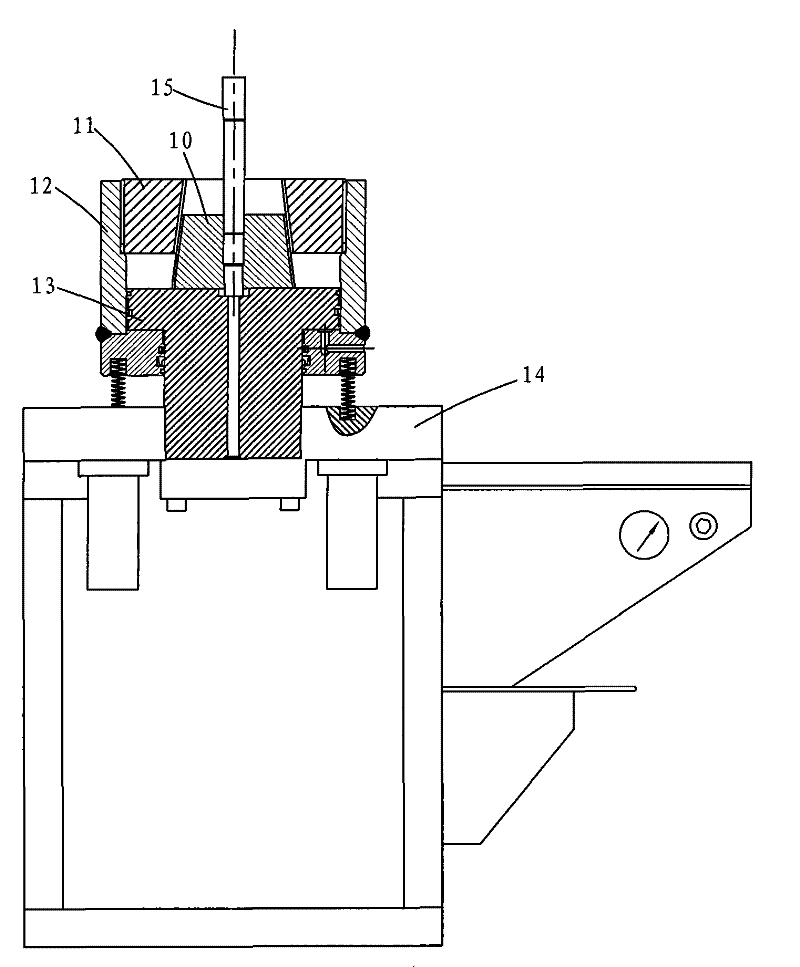

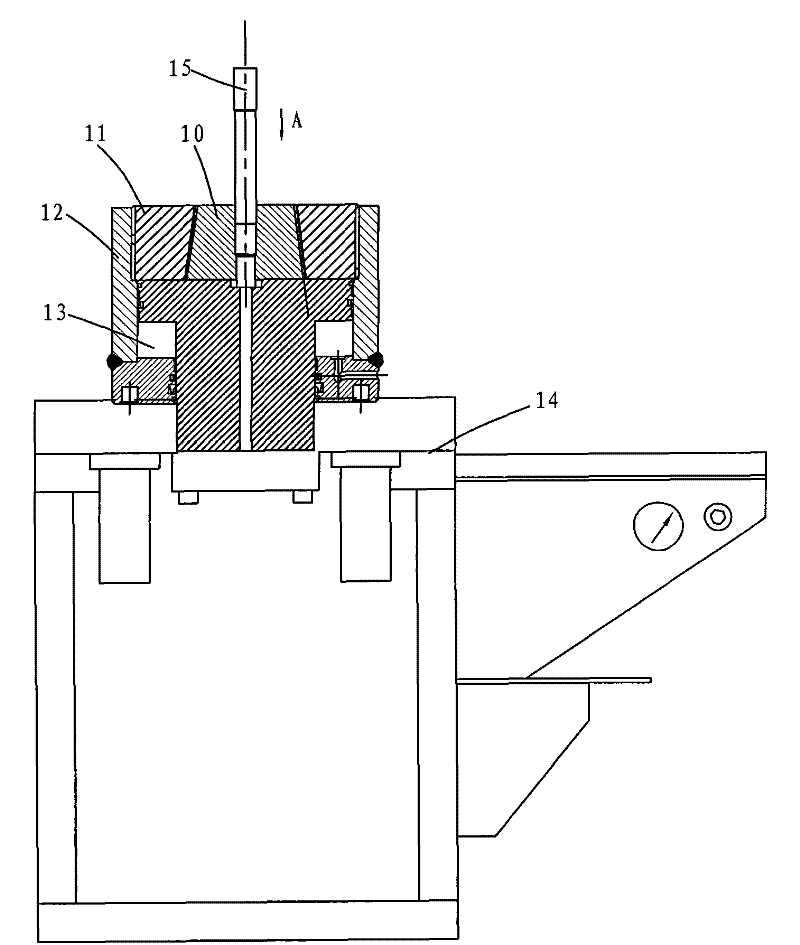

[0016] B, the outer diameter of the bottom of the seamless steel pipe is compressed, and the seamless steel pipe 15 after step A processing is sent into the crimping machine for processing, (referring to figure 2 , image 3 , Figure 4 ) The crimping machine is composed of a crimping module 10, a crimping mold core 11, a crimping oil cylinder 12, a crimping machine piston 13 and a crimping body 14. The crimping oil cylinder 12 is fixed on the crimping body 14 by a fixed support column. The crimping machine piston 13 is housed in the crimping oil cylinder 12. Eight crimping modules 10 are placed in the center of the crimping machine piston 13. The crimping modules 10 are distributed in a circle. Each crimping module 10 is long at the bottom and short at the top, forming a truncated cone. The inner sides of the eight crimping modules 10 are circled, and there is a gap for workpieces to be inserted in the center. The crimping mold core 11 is directly opposite to the top of the...

Embodiment 2

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com