Dipping and showering alternate type hank dyeing method

A dyeing method and alternating technology, applied in the field of textile printing and dyeing and hank dyeing, to achieve the effects of energy saving, water saving, sewage and carbon dioxide emissions, improving quality, and reducing sewage and carbon dioxide emissions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

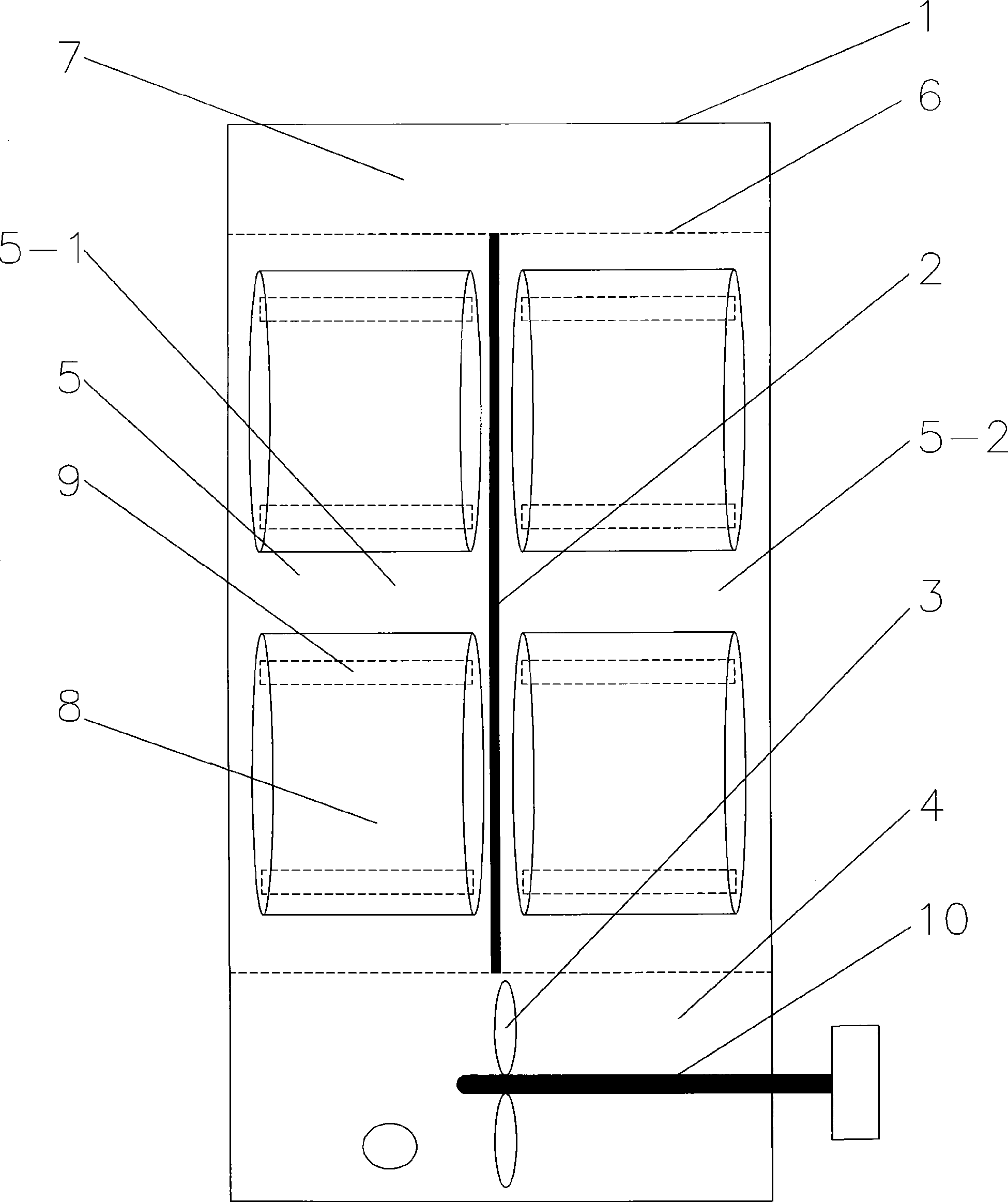

[0010] Such as figure 1 As shown, the soaking and alternating skein dyeing method described in this embodiment is to put a part of the skeins into the dye solution for dip dyeing, and the other part of the skeins to carry out leaching dyeing by pouring the dye solution. The leaching and Dip dyeing is carried out alternately. Said drip dyeing is a dyeing method in which the dye solution is poured on the skein yarn at intervals, and the dye solution flows down the skein yarn under the action of gravity. This dipping and alternating skein dyeing method uses a dye solution with a dyeing bath ratio of 1:14. The dye is a level-dyeing weak acid dye. The dyeing start temperature is 45°C, and the temperature is raised to 95°C at a rate of 1°C per minute. Finally, keep the temperature for 60 minutes, and the interval between forward and reverse conversion of the water pump is two minutes, so as to ensure that the dye liquor that plays the role of exhaust dyeing is alternately flowing i...

Embodiment 2

[0017] Such as figure 1 As shown, the immersion dyeing cabinet described in this embodiment is mainly composed of a cabinet body 1, a dye solution chamber 7 is provided on the upper part of the cabinet body 1 through an orifice plate 6, and a dye solution pool 4 is provided on the lower part of the cabinet body 1. A water pump 3 is provided in the dye liquor pool 4, and the water pump 3 is an axial flow pump, which is connected with a power unit through a transmission shaft 10 to provide power for the internal dye liquor circulation. The middle space of cabinet body 1 is divided into the cabinet interior space 5 of both sides by dividing plate 2, is provided with yarn bar 9 in cabinet interior space 5. When in use, the skein 8 is fixed on the yarn rod 9, and the rotation direction of the axial flow pump is intermittently and alternately reversed, so that the skein can be soaked and alternately dyed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com