Measuring method for thermostability of residual austenite in steel

A technology of retained austenite and measurement method, applied in the direction of material magnetic variables, etc., can solve the problems of low magnetic field strength, material can not reach the magnetic saturation state, large sampling size, etc., to achieve the effect of saving material and accurate quantitative calculation results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Pretreatment of steel

[0027] Select 1.02C-1.35Cr-0.33Mn-0.26Si high-carbon steel, cast, roll, and soften annealing. The softening annealing process is: heating at 1093K for 1h, slowly cooling to 963K at a rate of 10K / h, and then air cooling to room temperature. The quenching heating temperature is 1133K, and the holding time is 30min.

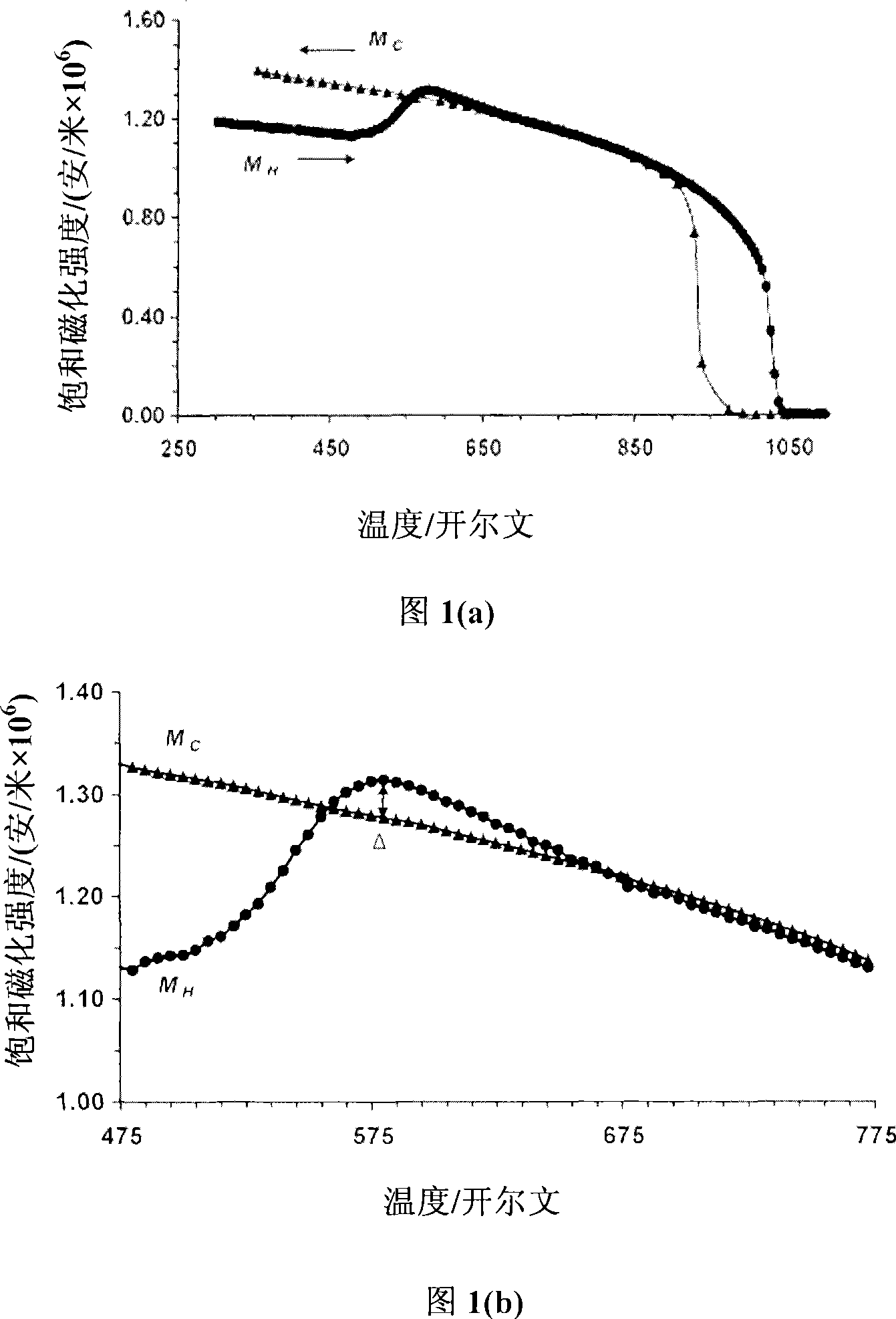

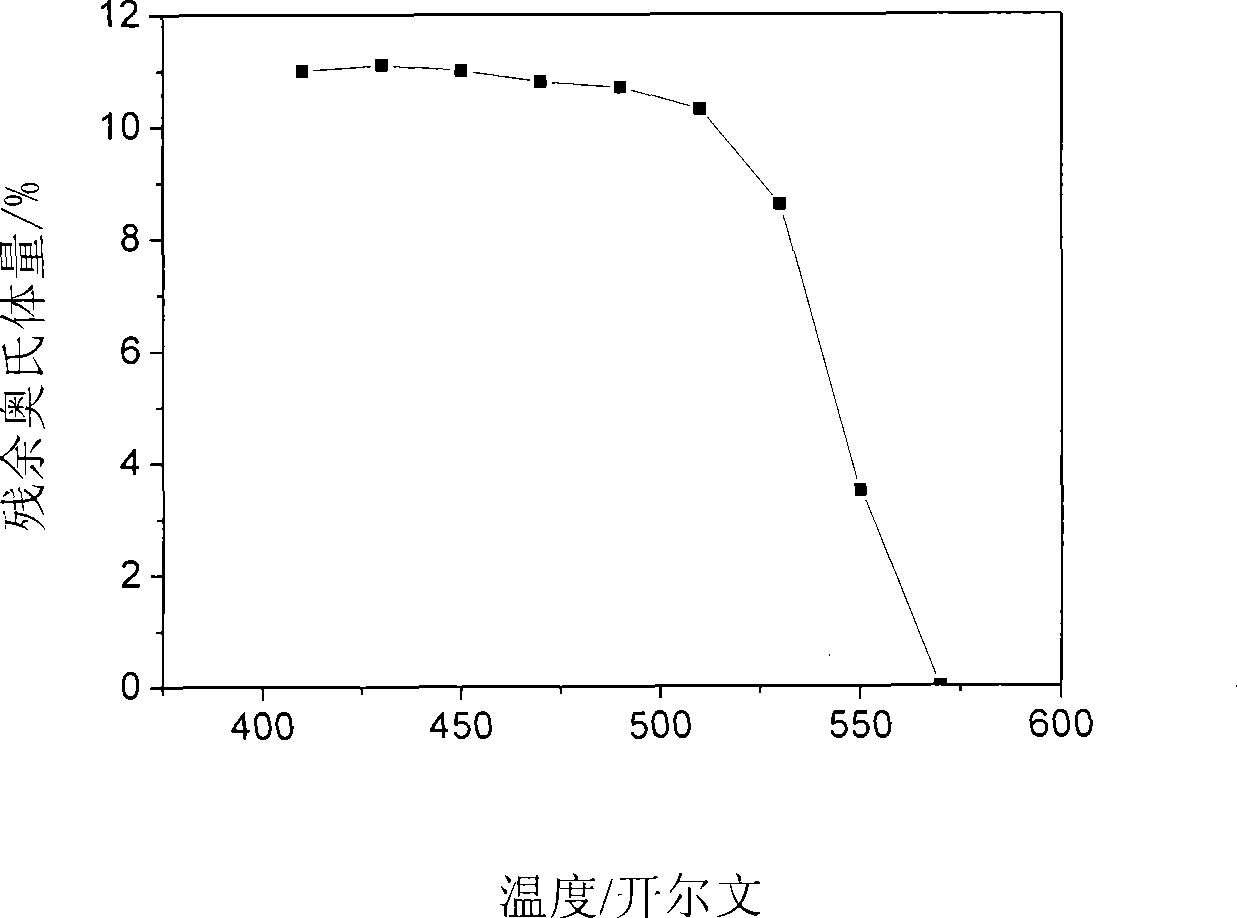

[0028] (2) Magnetic high temperature test

[0029] The quenched and heated sample is directly quenched to room temperature, and the quenched steel is cut into block samples with a diameter of 2 mm and a length of 2 mm by electric discharge method. Magnetic measurements were performed on a vibrating sample magnetometer. The vibrating sample magnetometer was calibrated with a nickel standard prior to testing. The temperature cycle range of high temperature magnetic measurement is 300K-1173K, and the applied magnetic field strength is 0.79×10 6 A / m. The heating rate for high temperature magnetic measurement is 3-5K / min, and the c...

Embodiment 2

[0033] (1) Pretreatment of steel

[0034] Select 1.02C-1.35Cr-0.33Mn-0.26Si high-carbon steel, cast, roll, and soften annealing. The softening annealing process is: heating at 1093K for 1h, slowly cooling to 963K at a rate of 10K / h, and then air cooling to room temperature. The quenching heating temperature is 1133K, and the holding time is 30min.

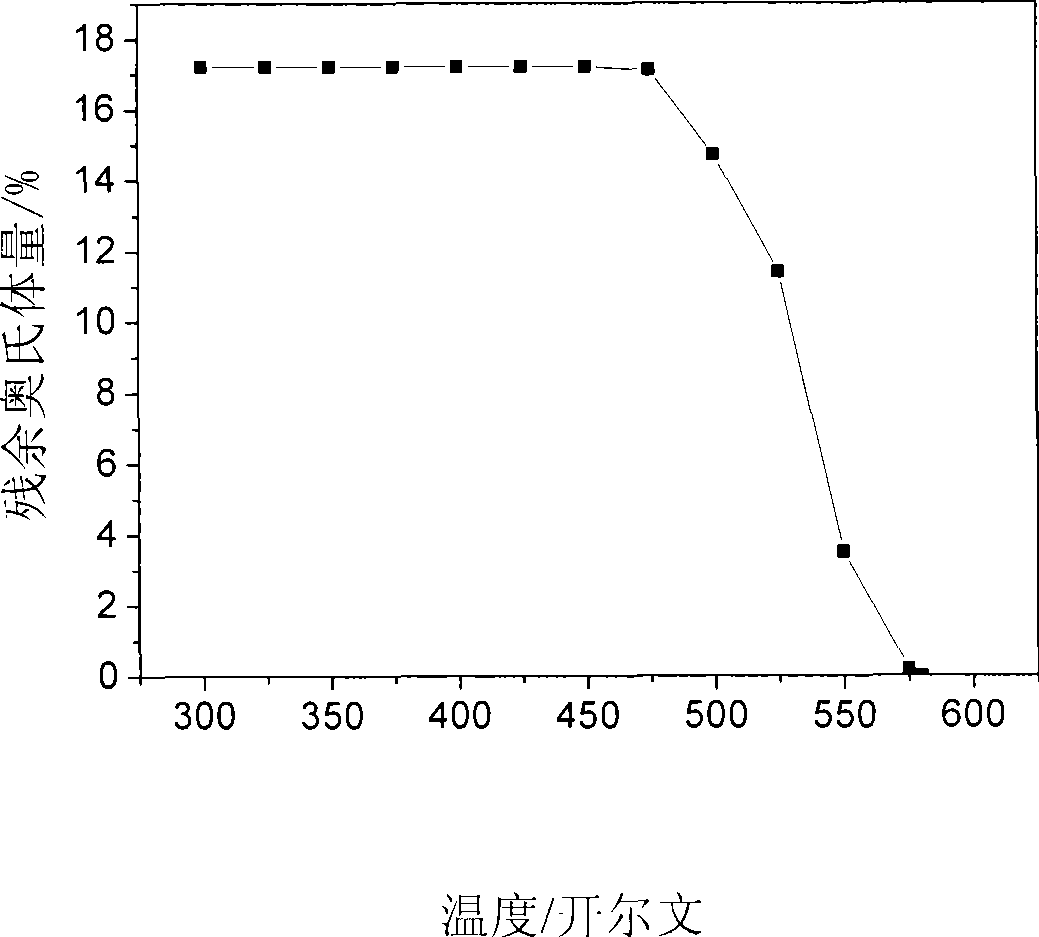

[0035] (2) Magnetic high temperature test

[0036] The quenched and heated sample was quenched to 503K and kept for 40 minutes, and the austempered steel was cut into block samples with a diameter of 2 mm and a length of 2 mm by electric discharge method. Magnetic measurements were performed on a vibrating sample magnetometer. The vibrating sample magnetometer was calibrated with a nickel standard prior to testing. The temperature cycle range of high temperature magnetic measurement is 300K-1173K, and the applied magnetic field strength is 0.79×10 6 A / m. The heating rate for high temperature magnetic measurement is 3-5K / min, a...

Embodiment 3

[0040] (1) Pretreatment of steel

[0041] Select 1.02C-1.35Cr-0.33Mn-0.26Si high-carbon steel, cast, roll, and soften annealing. The softening annealing process is: heating at 1093K for 1h, slowly cooling to 963K at a rate of 10K / h, and then air cooling to room temperature. The quenching heating temperature is 1133K, and the holding time is 30min.

[0042] (2) Magnetic low temperature test

[0043] The quenched and heated sample was quenched to 503K and kept for 40 minutes, and the austempered steel was cut into block samples with a diameter of 2 mm and a length of 2 mm by electric discharge method. Magnetic measurements were performed on a vibrating sample magnetometer. The vibrating sample magnetometer was calibrated with a nickel standard prior to testing. The temperature cycle range of low temperature magnetic measurement is 300K-10K, and the applied magnetic field strength is 0.79×10 6 A / m. The heating and cooling rates for low temperature magnetic measurements are bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com