Method for quenching end socket ribbet position of assembled camshaft

A camshaft and assembled technology, applied in the direction of quenching agent, furnace type, furnace, etc., can solve the problems of difficult positioning of parts, uniform distribution of hardened layer, short process time, etc., and achieve shortened heat conduction time, short process time and excellent structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

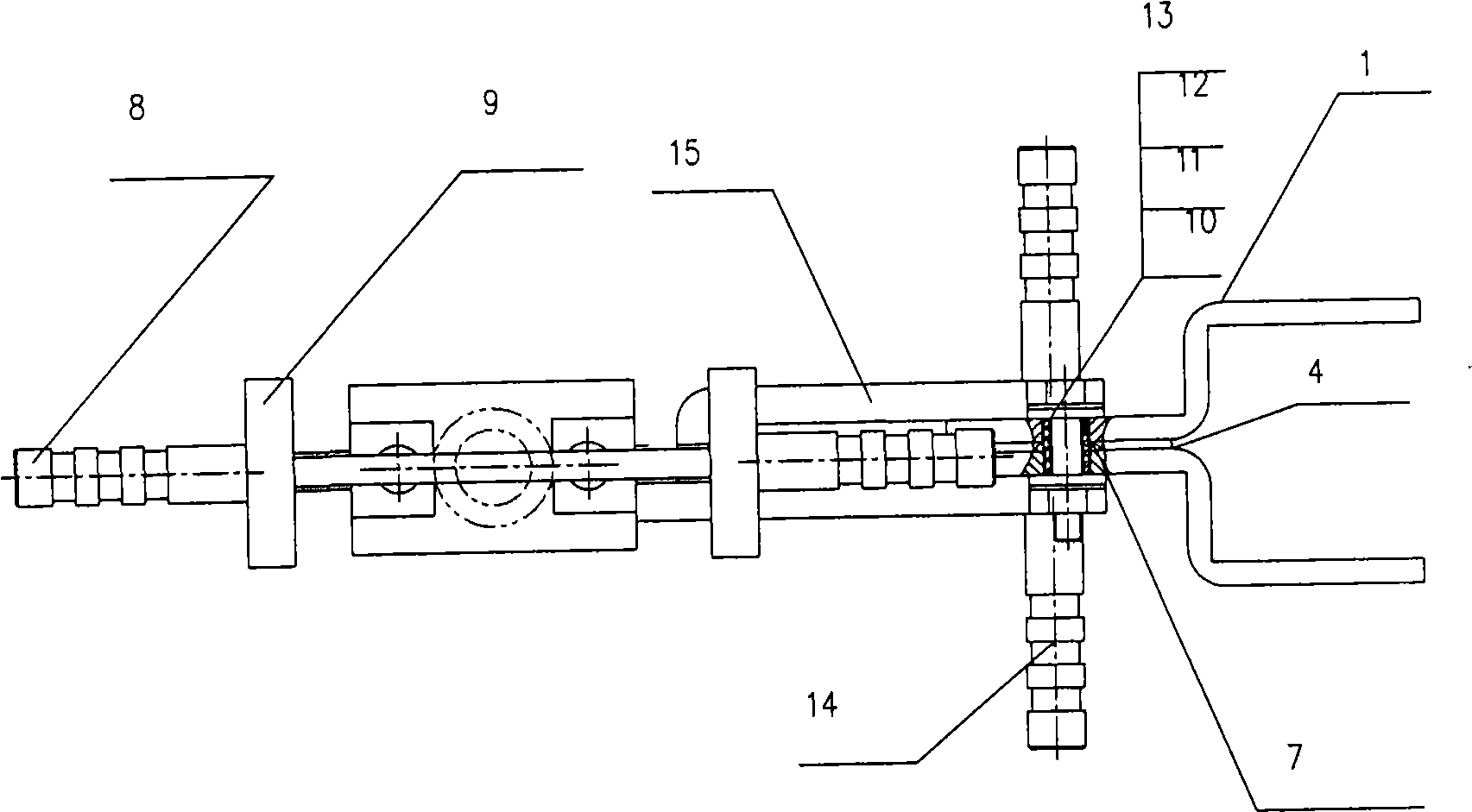

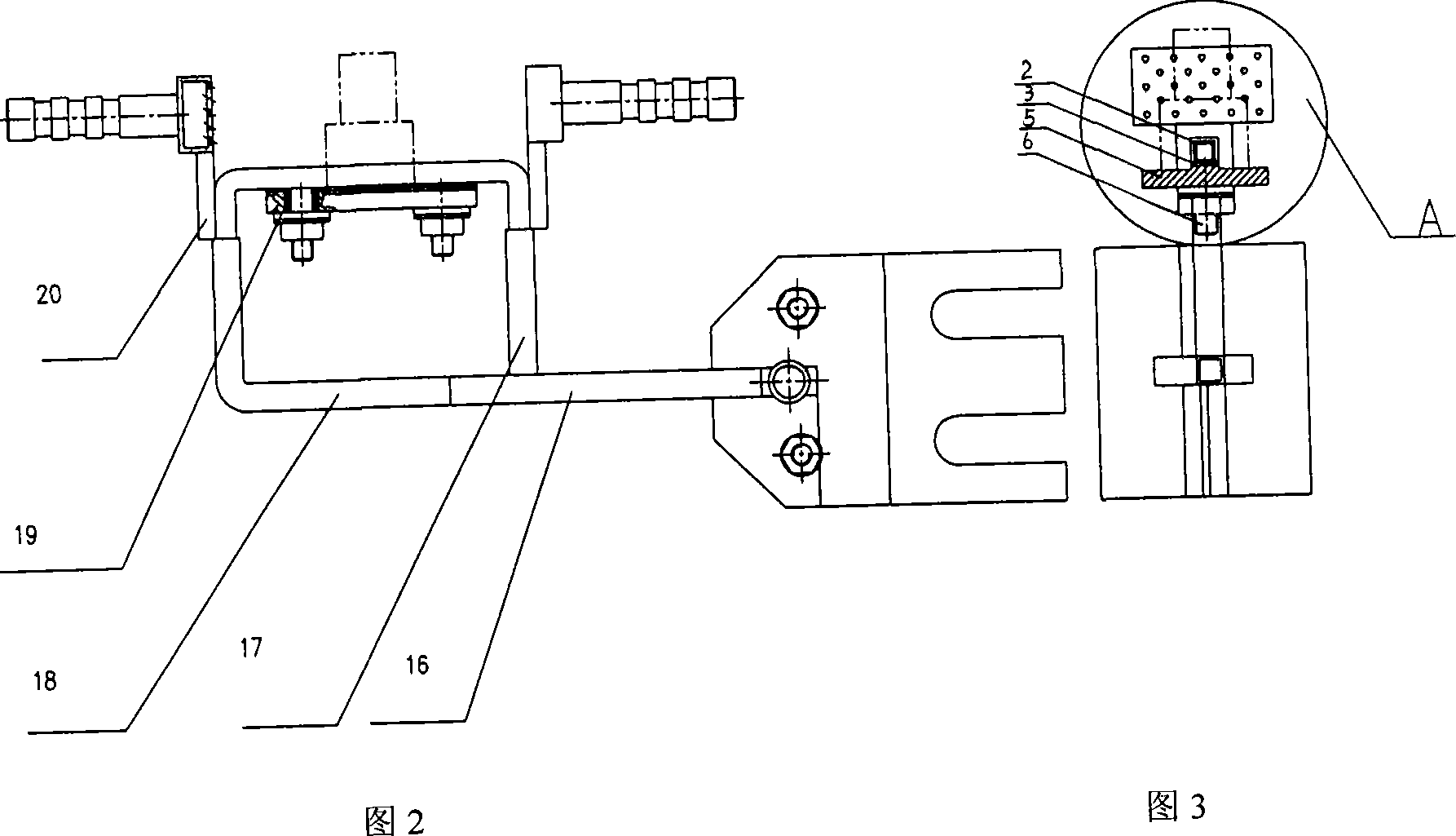

[0011] The present invention will be further described below in conjunction with the accompanying drawings: as shown in the figure, the method for quenching the notch of the end of the assembled camshaft is characterized in that: its specific process steps are as follows: (A) quenching the contact plate 1 of the quenching inductor The quenching transformer of the machine tool is fastened together; under the condition that the cooling water and quenching water channel are guaranteed to be unobstructed, place the notch of the part downward on the positioning plate 5, which is on a 6mm thick red copper plate with magnetic shielding effect A boss with a width of 7.9mm and a height of 1mm is processed as a positioning platform, so that the notch of the part sits on the boss to limit the up and down position of the part. In order to limit the position of the part along the effective wire 2, it will be used for positioning Plate 5 and effective wire 2 are insulated and heat-resistant ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap