Magnetic induction measurement method and apparatus

A magnetic induction intensity and measuring device technology, which is applied in the direction of the magnitude/direction of the magnetic field, and the use of magneto-optical equipment for magnetic field measurement, etc., can solve problems such as difficult drawing, high price, and complex optical signal detection system

- Summary

- Abstract

- Description

- Claims

- Application Information

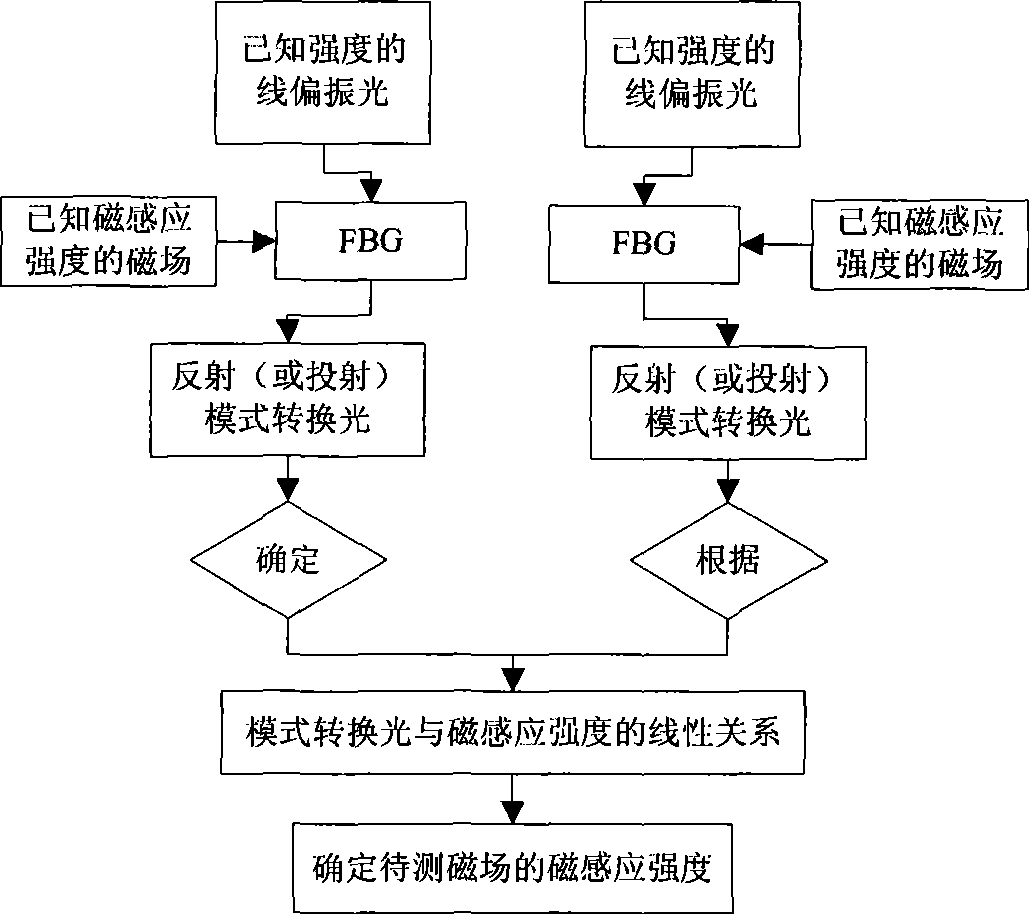

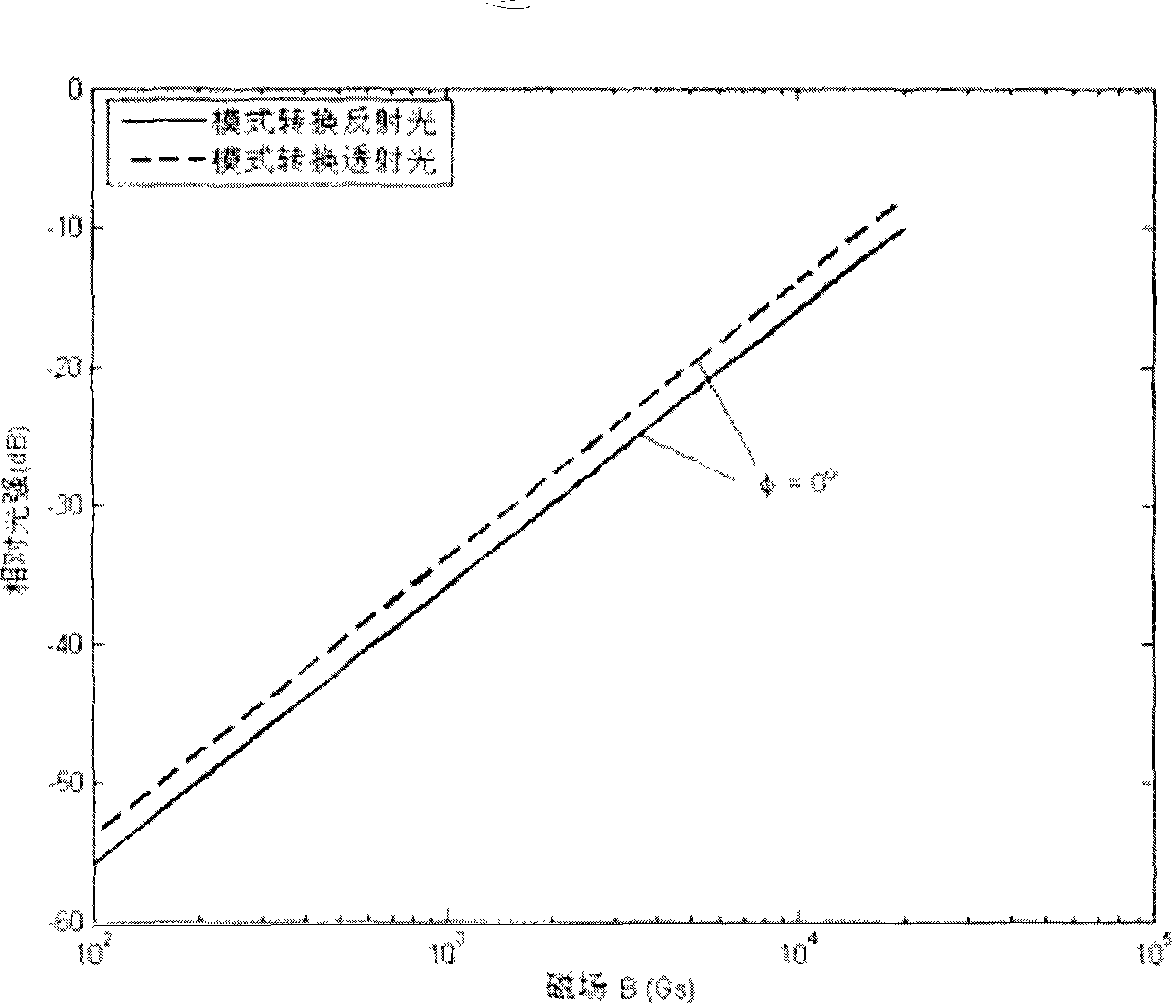

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

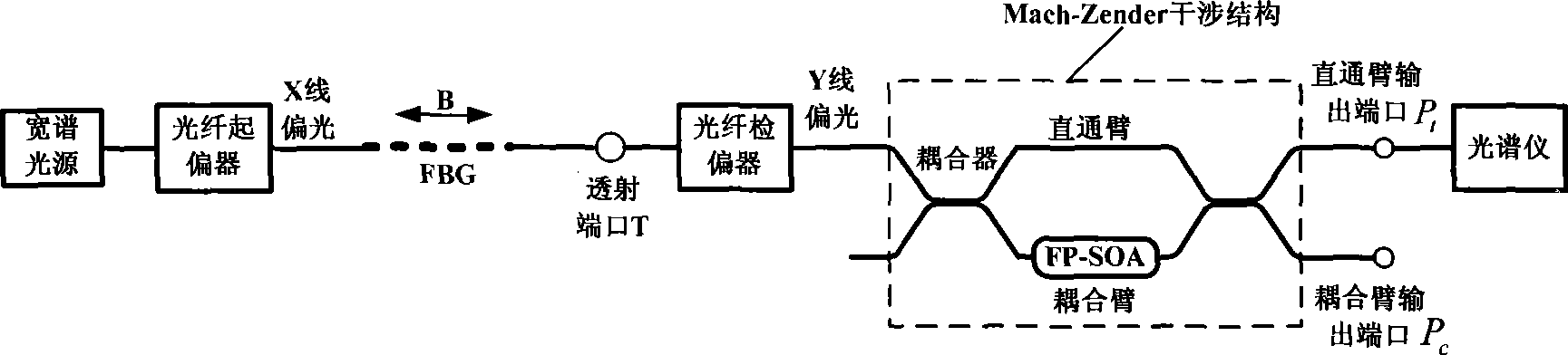

[0018] According to a method for measuring magnetic induction provided by the present invention, a transmission type magnetic induction measuring device, such as image 3 As shown, it includes broadband light source, fiber polarizer, fiber grating (FBG), fiber analyzer, tunable Farpert semiconductor optical amplifier (FP-SOA) and spectrometer. The output light of the broadband light source is incident on the FBG after being polarized by the optical fiber polarizer, and the transmitted light of the FBG under the action of an external magnetic field is analyzed by the optical fiber analyzer perpendicular to the polarization direction of the optical fiber polarizer and converted into mode-converted transmitted light; the mode-converted transmitted light is amplified by an adjustable FP-SOA and then input to a spectrometer.

[0019] In the above technical solution, only one adjustable FP-SOA is used between the polarizer and the spectrometer. In the actual measurement process, in...

specific Embodiment approach 2

[0020] According to a method for measuring magnetic induction provided by the present invention, a reflective magnetic induction measuring device, such as Figure 4 As shown, it includes broadband light source, fiber polarizer, optical circulator, fiber Bragg grating (FBG), fiber analyzer, tunable Faber Semiconductor Optical Amplifier (FP-SOA) and spectrometer. The output light of the broadband light source is polarized by the optical fiber polarizer and is incident into the FBG through the optical circulator. The vertical optical fiber analyzer converts the reflected light into mode conversion after analyzing the polarization; the mode converted reflected light is amplified by the adjustable FP-SOA and then input to the spectrometer.

[0021] In the above technical solution, only one adjustable FP-SOA is used between the polarizer and the spectrometer. In the actual measurement process, in order to increase the optical amplification effect of the FP-SOA so that the spectrome...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com