Polyester melt viscosity control system and control method thereof

A technology of viscosity control and polyester melt, applied in control/adjustment system, viscosity control, non-electric variable control, etc., can solve problems such as waste, deviation between measured value and actual value, affecting product quality, etc., to improve viscosity control Level, simple structure, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

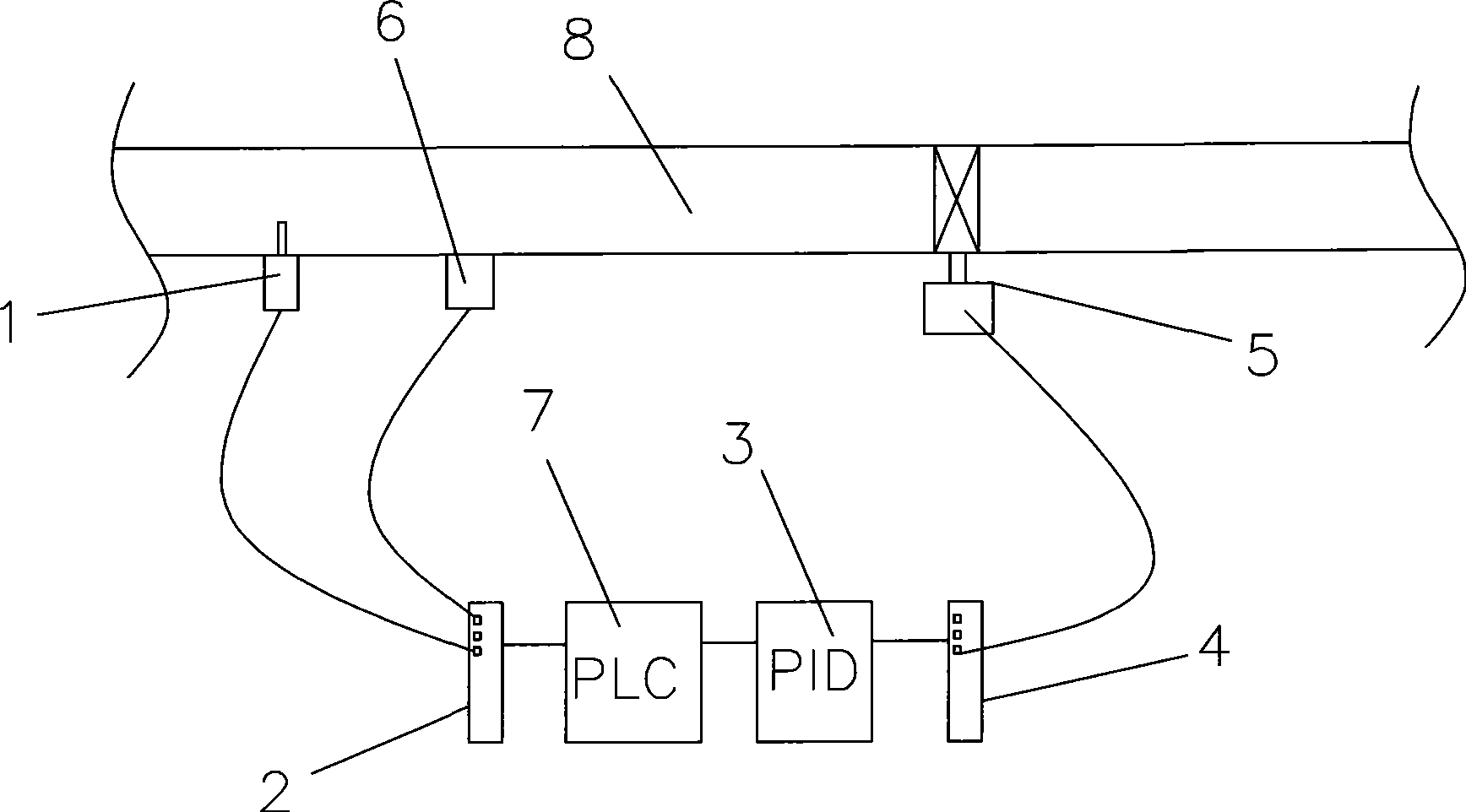

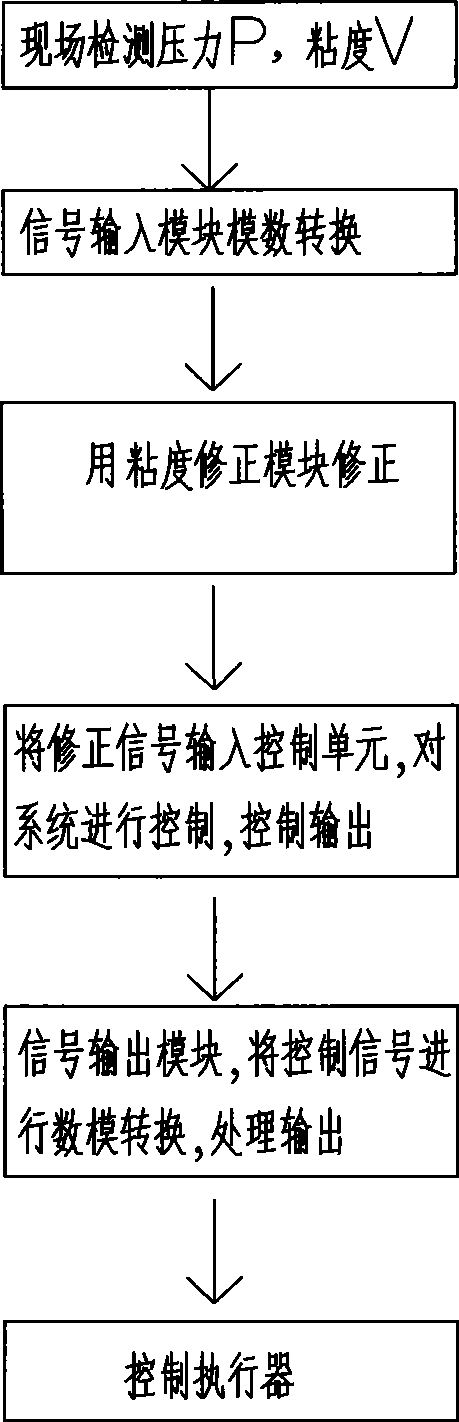

[0014] Such as figure 1 As shown, the polyester melt viscosity control system described in the present invention mainly includes an oscillating viscometer 1, a signal input unit 2, a control unit 3, a signal output unit 4 and an actuator 5, and the actuator 5 is arranged on the polyester On the pipeline 8, the oscillating viscometer 1 is connected to the signal input unit 2, and the signal output unit 4 is connected to the actuator 5. The polyester pipeline 8 is provided with a pressure detector 6, a pressure detector 6 and an oscillating viscometer. Viscometer 1 is connected with viscosity correction unit 7 through signal connection, and described viscosity correction unit 7 is the PLC of a Siemens S7300, and there is algorithm program written with ladder diagram in the memory of PLC, and this algorithm program is used to realize function The signal input unit 2 is a Siemens analog input unit SM331, the control unit 3 is a PID regulator, the signal output unit 4 is an analog...

Embodiment 2

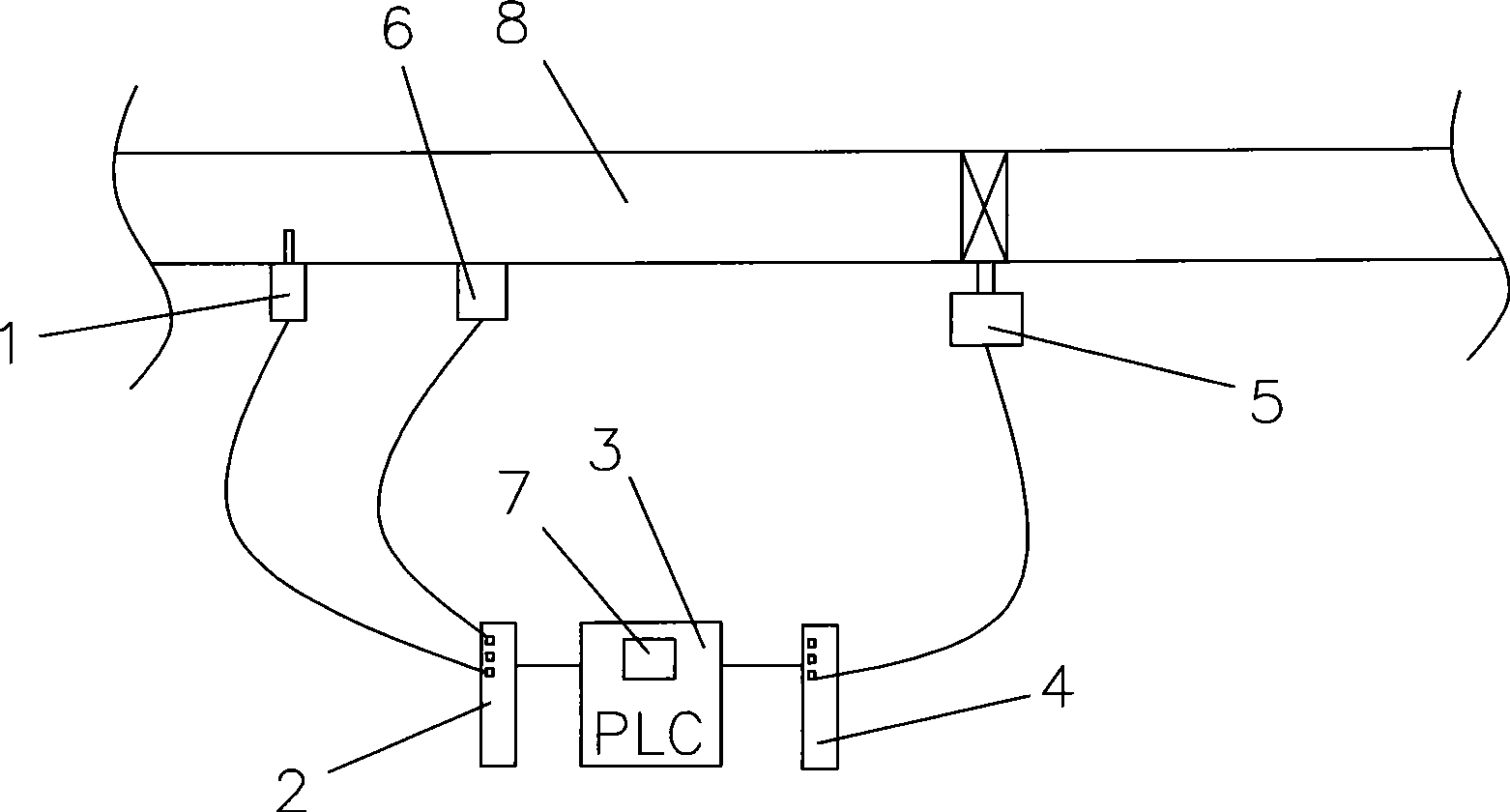

[0018] Such as image 3 As shown, the polyester melt viscosity control system described in the present invention mainly includes an oscillating viscometer 1, a signal input unit 2, a control unit 3, a signal output unit 4 and an actuator 5, and the signal input unit 2 It is the Siemens analog input unit SM331, the control unit 3 is Siemens S7300PLC, the signal output unit 4 is the Siemens analog output unit SM332, the actuator 5 is the regulating valve, the oscillating viscometer 1 and the regulating valve are arranged on the polyester pipeline 8, The oscillating viscometer 1 is electrically connected to the PLC through the SM331, the analog signal detected on site is input to the PLC through the analog-to-digital conversion of the SM331, and the PLC is electrically connected to the regulating valve through the SM332, and the polyester pipeline 8 is provided with a pressure detector 6, The pressure detector 6 and the oscillating viscometer 1 are connected with a viscosity corr...

Embodiment 3

[0021] Such as Figure 4 As shown, the polyester melt viscosity control system described in the present invention integrates the signal input unit 2, control unit 3, and signal output unit 4 of embodiment 2 into a DCS system, and the viscosity correction unit 7 formula Put it directly in the DCS controller, where the K value of 0.375 is solidified in the program, P 0 It is detected by the pressure detector 6 in the initial state, P is detected by the pressure detector 6 during the production process, and V 检测粘度 Measured by an oscillating viscometer 1.

[0022] Add the viscosity correction unit 7 formula in the viscosity control program of the DCS controller The oscillating viscometer 1 sends the polyester viscosity detection signal to the DCS computer control system. The DCS computer control system first filters the viscosity detection signal and the pressure signal, and then corrects it by the viscosity correction unit 7 program to eliminate the pressure on the viscosity....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com