Manufacturing method for titanium hydride powders

A titanium hydride, powder technology, applied in chemical instruments and methods, transition element hydrides, inorganic chemistry, etc., to reduce energy costs, improve productivity, and reduce manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

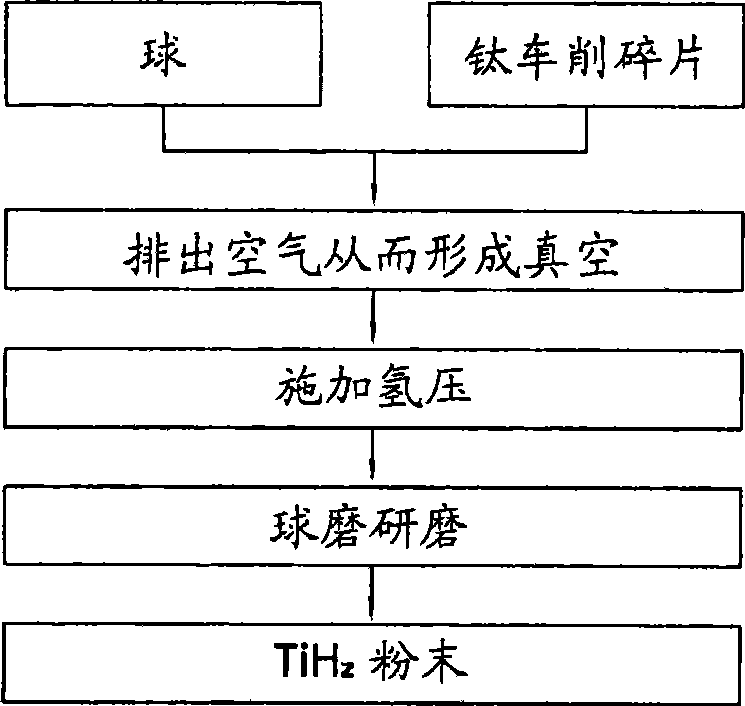

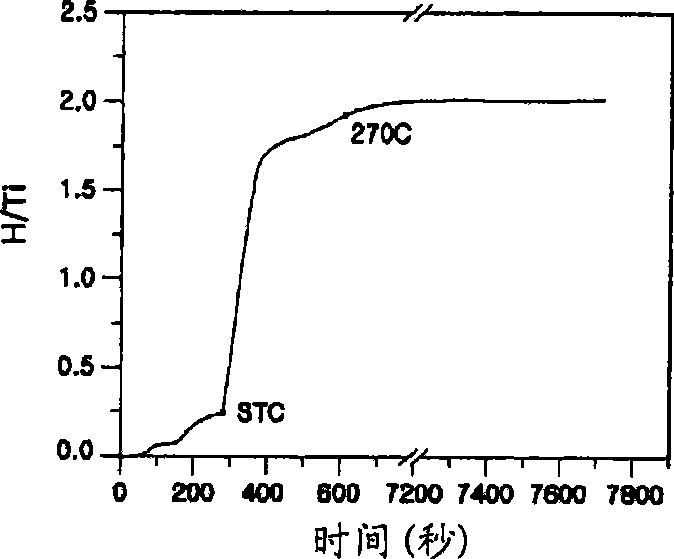

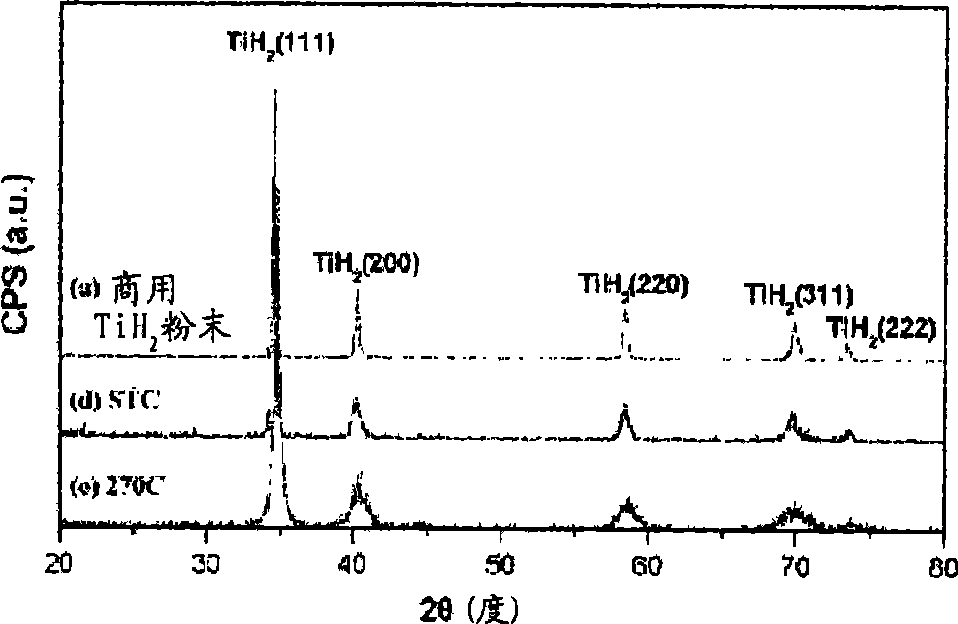

[0026] figure 1 is a schematic diagram illustrating a method of manufacturing titanium hydride powder according to an embodiment of the present invention. figure 2 is to show that when TiH is produced by the method according to the embodiment of the present invention 2 A graph of the relationship between milling time and the amount of hydrogen absorbed when powdered. image 3 is to show that TiH produced by the method according to the embodiment of the present invention 2 A graph of the X-ray diffraction analysis results of the powder. Figure 4 is to show that TiH produced by the method according to the embodiment of the present invention 2 Graph of DTA analysis results of the powder.

[0027] Such as figure 1 As shown in , the method of manufacturing titanium hydride according to an embodiment of the present invention includes filling titanium turning chips and balls into a container, exhausting air from the container to form a vacuum in the container, applying hydroge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com