Automatic unloading line for recrement

An automatic unloading and gangue technology, which is applied in the direction of loading/unloading, transporting passenger cars, railway car body parts, etc., can solve the problems of continuous extension of difficult gangue stacking sites, multiple supporting equipment for infrastructure construction work, and large working area, so as to reduce labor costs Operation and dispatching links, improving transshipment efficiency, and equipped with reasonable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

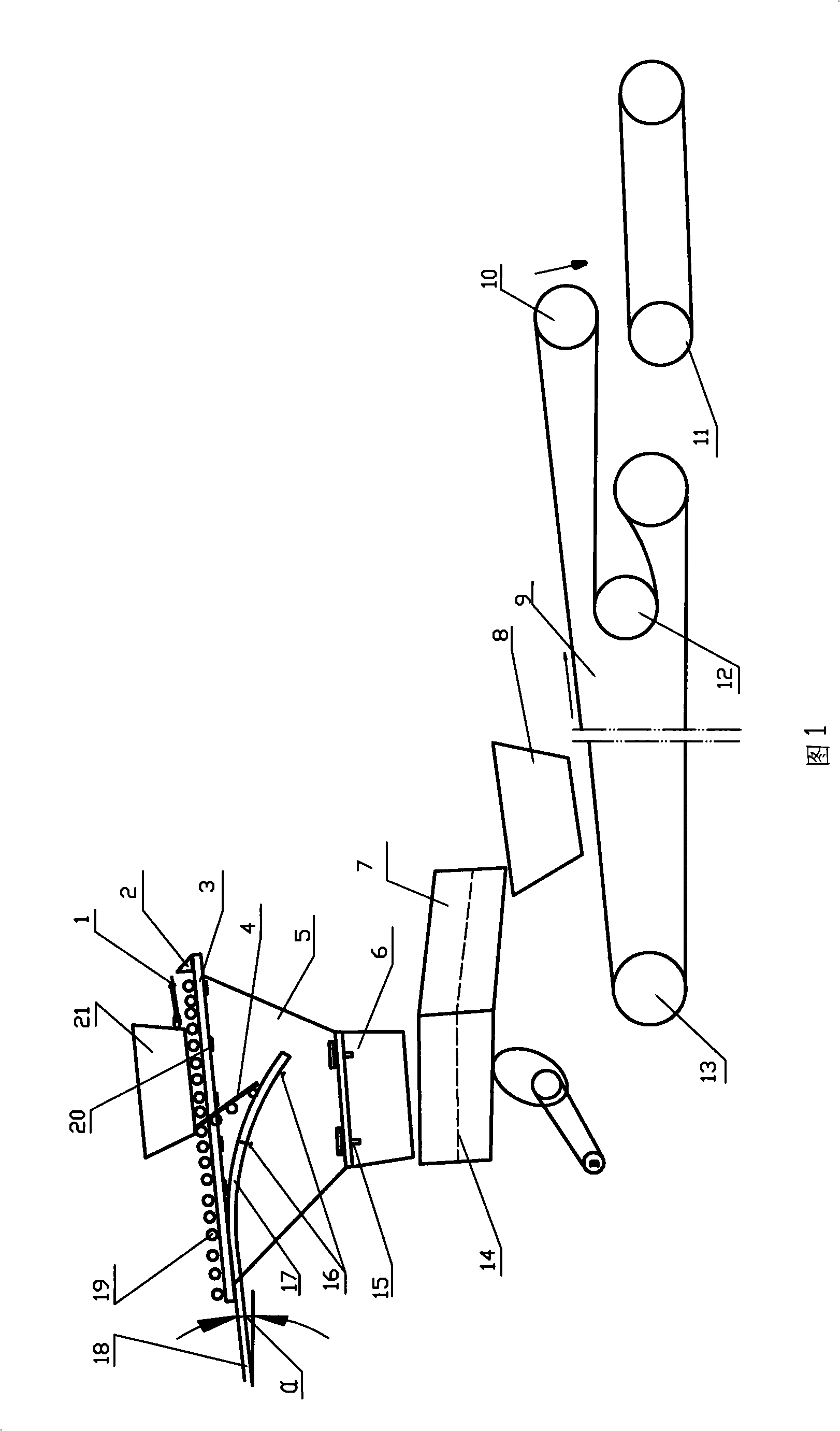

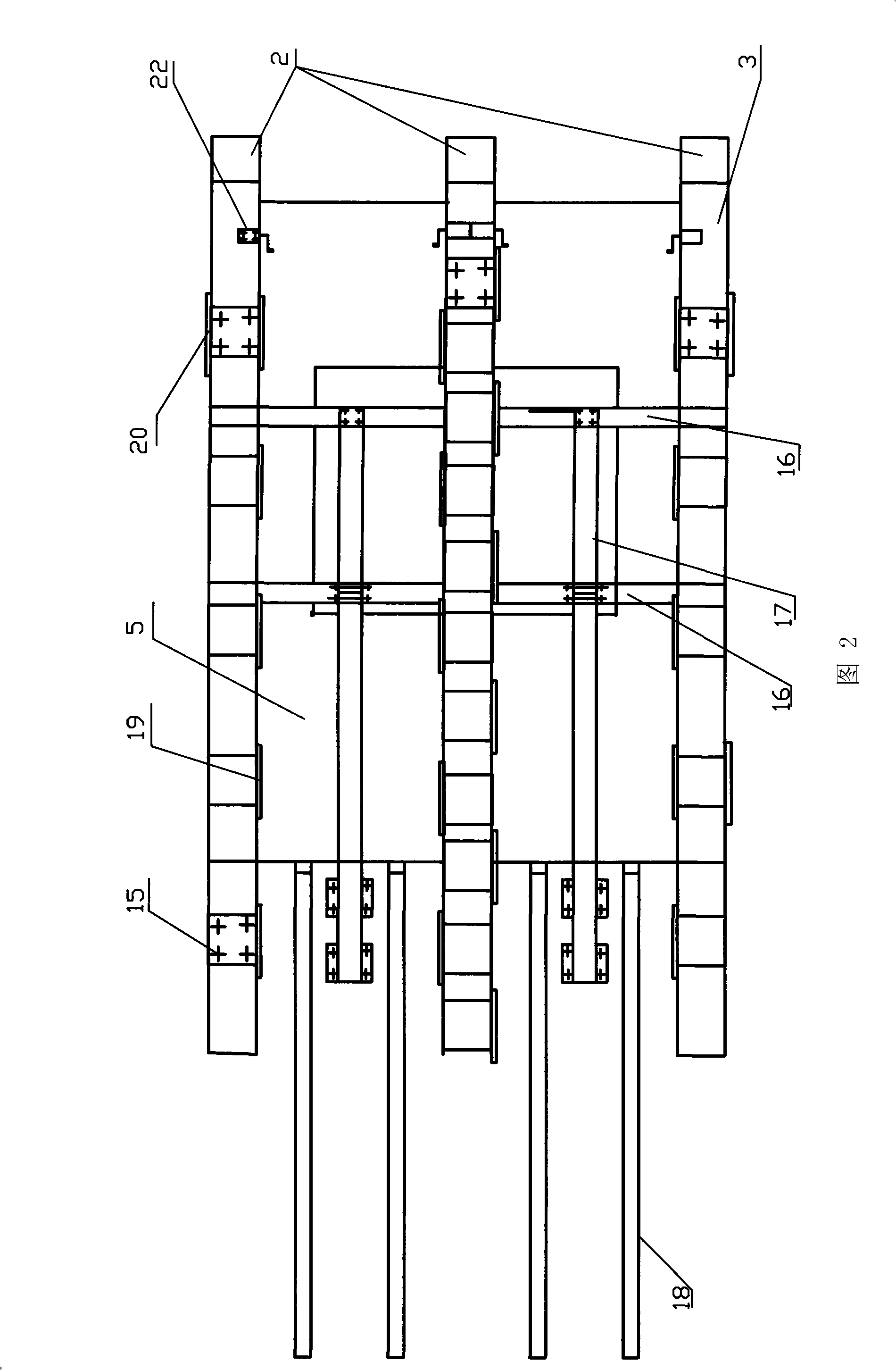

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0030] The first embodiment is an automatic gangue unloading line for an average daily discharge of 1,000 tons of gangue, where the gangue output distribution point is 1 km away from the gangue centralized stacking point, see figure 1 with 2 .

[0031] This example gangue automatic unloading line track 18 parts, laying retracking. The bottom unloading mine car that runs on track weighs about 2500Kg, and the compartment 21 payload that adds weight increases 7000Kg. The beginning of the track is set at the gangue collection and distribution point, and the end of the track is higher than the beginning. Combined with the site terrain along the line, a downhill slope angle of about 9-21 degrees is maintained from the end to the beginning. Far from the terminal, there are 2×185kw double-drum hoists, the front ends of the two bottom-loading mine ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com