Water purifier

A technology of water purifier and water storage tank, applied in the field of water treatment, can solve the problems of high cost, short service life, complex process, etc., achieve the effect of reducing cost and energy consumption, and inhibiting the growth of bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

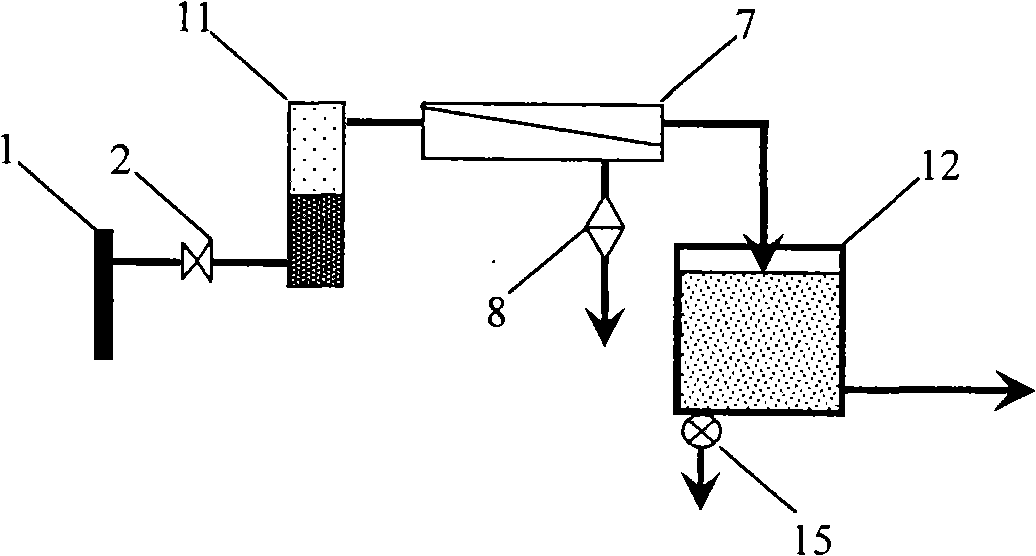

[0018] Water purifier of the present invention can adopt as figure 2 In the shown system, the inlet of non-woven fabric and granular activated carbon combined filter element 11 is connected to tap water 1 through valve 2, the outlet of non-woven fabric and granular activated carbon combined filter element 11 communicates with the inlet of nanofiltration membrane module 7, and the inlet of nanofiltration membrane module 7 The outlet water passes into the water storage bucket 12, and the water storage bucket 12 communicates with the drainage system 15 with a timing automatic drainage function. Municipal tap water passes through non-woven fabric and granular activated carbon pre-treatment combination filter element 11 and nanofiltration membrane 7 successively, and the purified water enters the water storage tank 12 for storage. When the purified water stored in the water storage tank 12 exceeds the time set by the automatic drainage system 15 , Unused clean water can be complet...

Embodiment 2

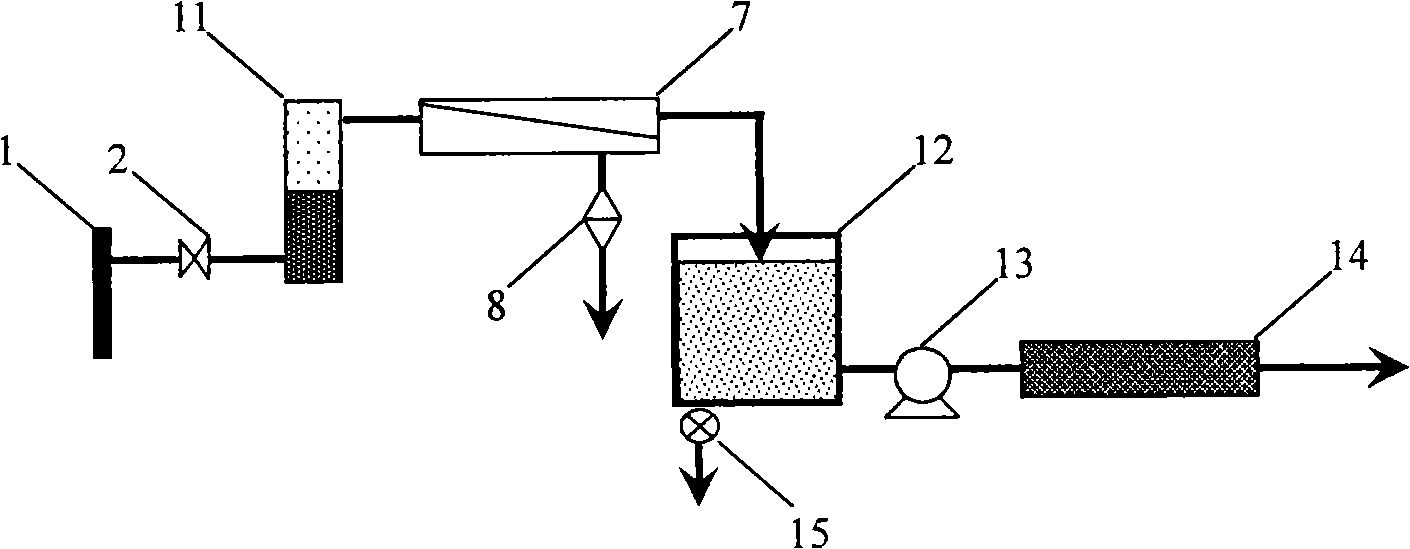

[0025] Water purifier of the present invention can adopt as image 3 In the shown system, the inlet of non-woven fabric and granular activated carbon combined filter element 11 is connected to tap water 1 through valve 2, the outlet of non-woven fabric and granular activated carbon combined filter element 11 communicates with the inlet of nanofiltration membrane module 7, and the inlet of nanofiltration membrane module 7 Outlet water passes into water storage bucket 12, and water storage bucket 12 communicates with drainage system 15 with timing automatic drainage function, and sterilization system 14 communicates with water storage bucket 12 through low-pressure outlet water pump 13. Wherein the sterilization system 14 adopts a KDF filter. The low-pressure water outlet pump 13 can keep the water outlet flow rate above 2L / min, and the KDF filter can use a stainless steel filter column with a diameter of 22mm and a length of 100mm, and the packing density is 1.5g / cm 3 to 2g / cm...

Embodiment 3

[0032] Water purifier of the present invention can adopt as image 3 In the shown system, the sterilizing system 14 adopts ultraviolet lamps, the tap water passes through the non-woven fabric and granular activated carbon pretreatment combination filter element 11, the nanofiltration membrane 7, and the purified water enters the water storage tank 12 for storage, and finally passes through the low-pressure water outlet pump 13 and passes through the ultraviolet light. Lamp to sterilize.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com