Heat exchange system for producing substrate

The technology of a heat exchange system and a heat exchange device is applied in the field of the heat exchange system of the substrate manufacturing process, which can solve the problems of insufficient market demand, large power consumption of the electric heating wire, factory losses, etc., so as to reduce the production cost and increase the electric heating device. , The effect of device structure improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, Features and their functions are described in detail below. For convenience of description, in the following embodiments, the same elements are denoted by the same numbers.

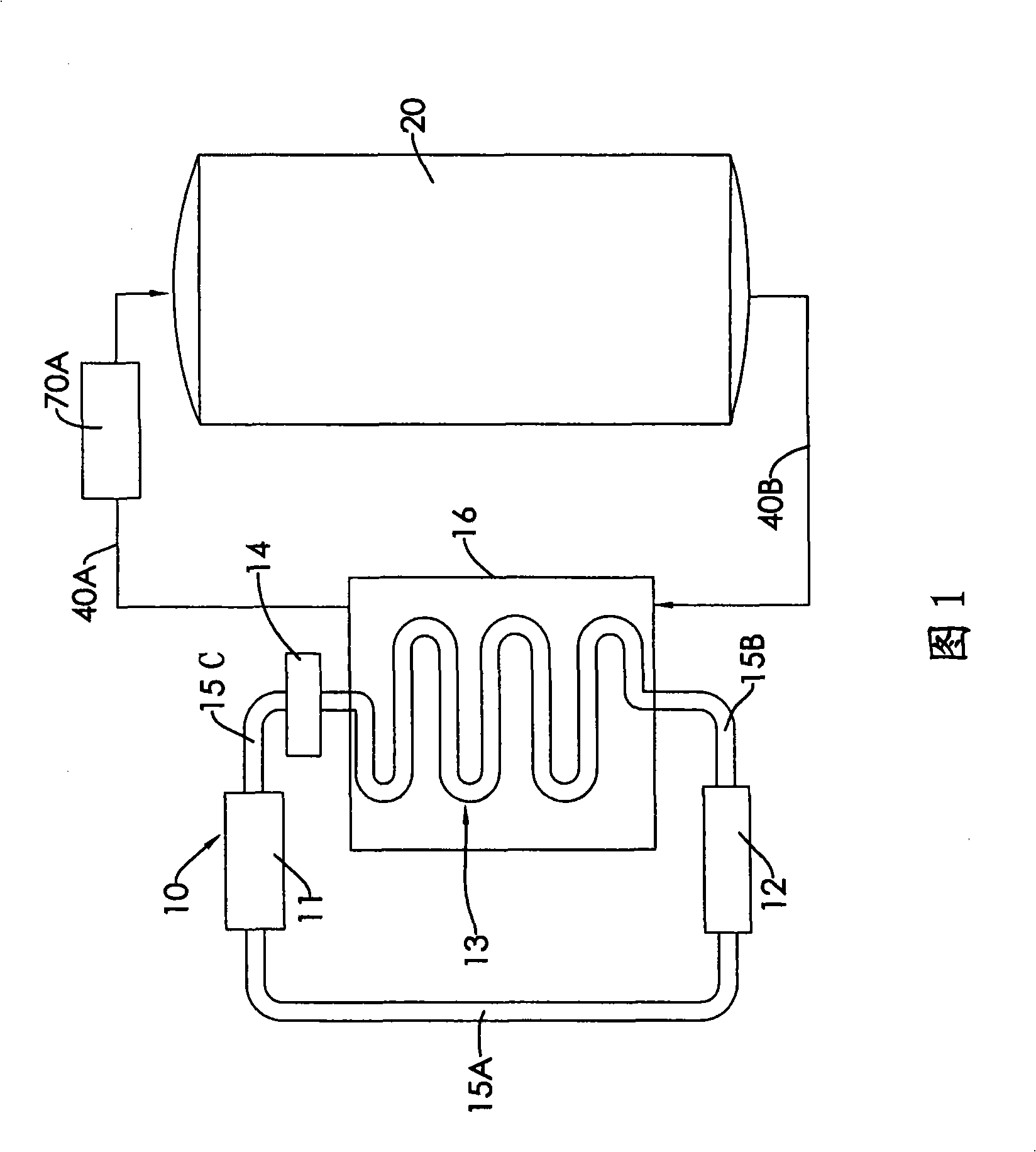

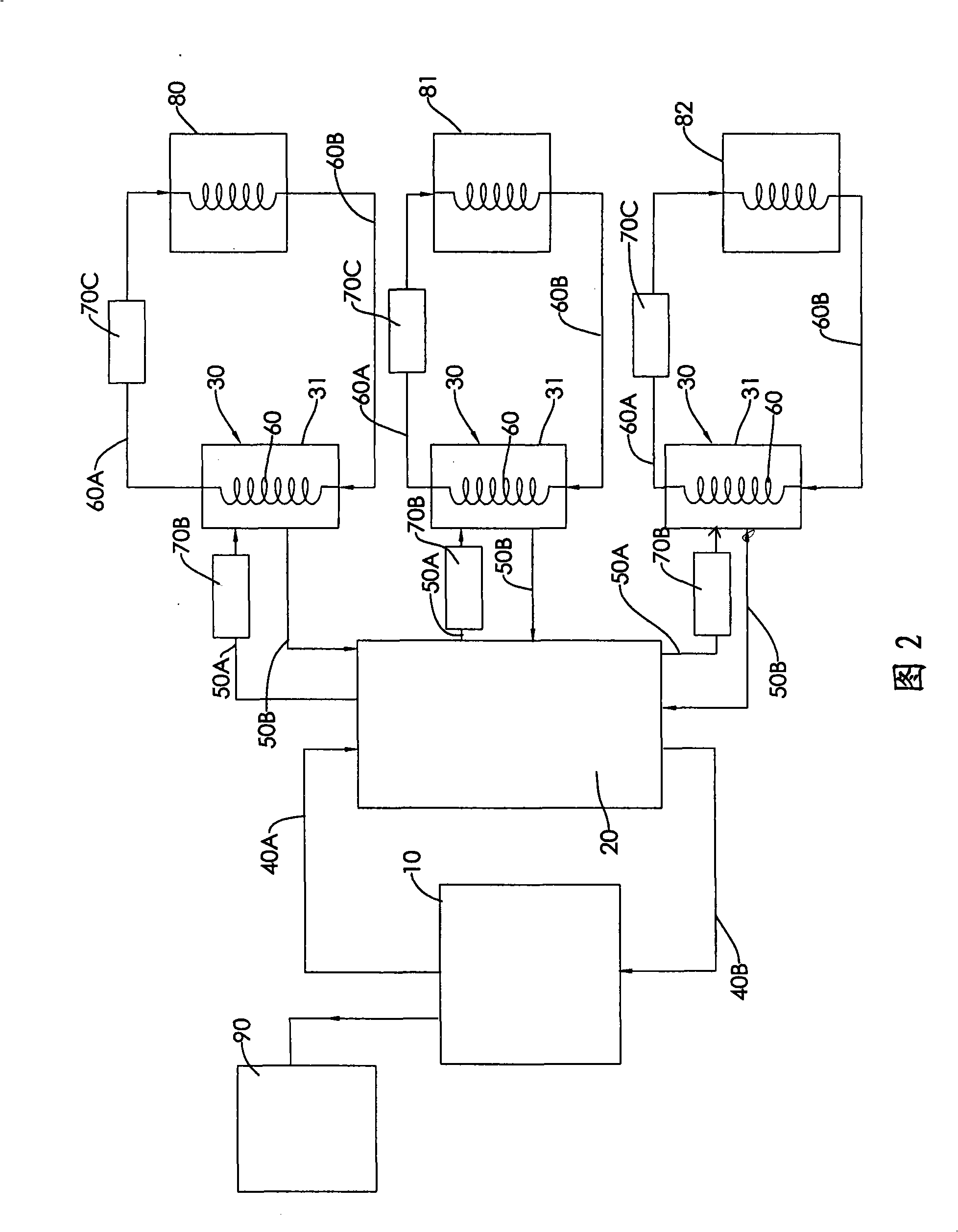

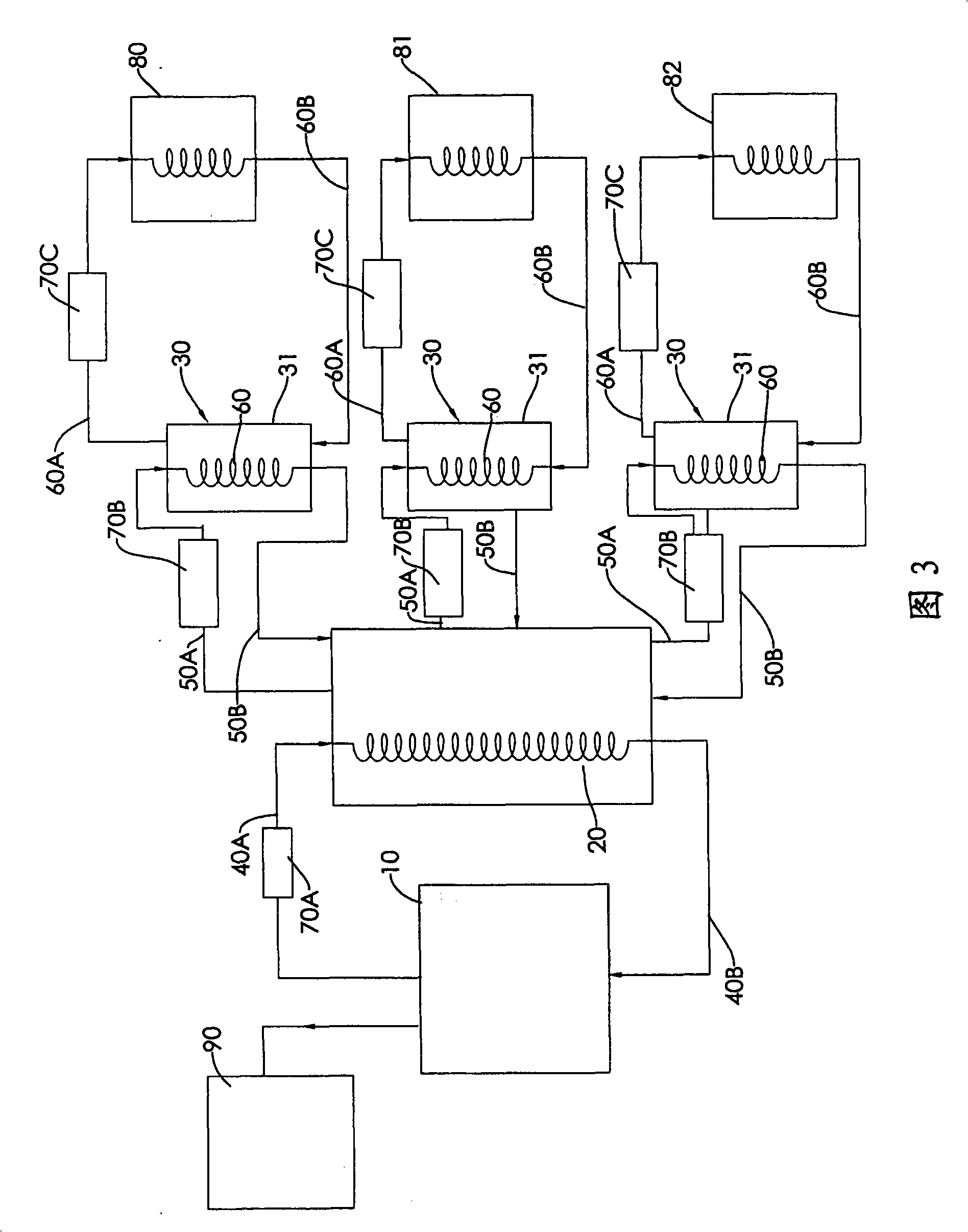

[0034] Please refer to figure 1 and figure 2 , is an embodiment of a heat exchange system of the present invention, consisting of a heat pump device 10, a heat collecting device 20, more than one heat exchange device 30, more than two connecting pipes 40A and 40B, and more than two distribution pipes 50A and 50B and more than one delivery pipe 60.

[0035] This heat pump device 10 is made up of an evaporator 11, a compressor 12, a condenser 13, an expansion valve 14 and a plurality of through pipes 15A, 15B, 15C, and the evaporator 11 is connected to the Between the expansion valve 14 and the compressor 12, and the conden...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com