Method for detecting rotate speed of flooding point of mixing kettle

A detection method and technology of stirring speed, which are applied in fluid velocity measurement, velocity/acceleration/impact measurement, measurement device and other directions, can solve the problems of inappropriate opaque stirring device, limited application range, low sensitivity, etc. The effect of a wide range of applications and low measurement conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

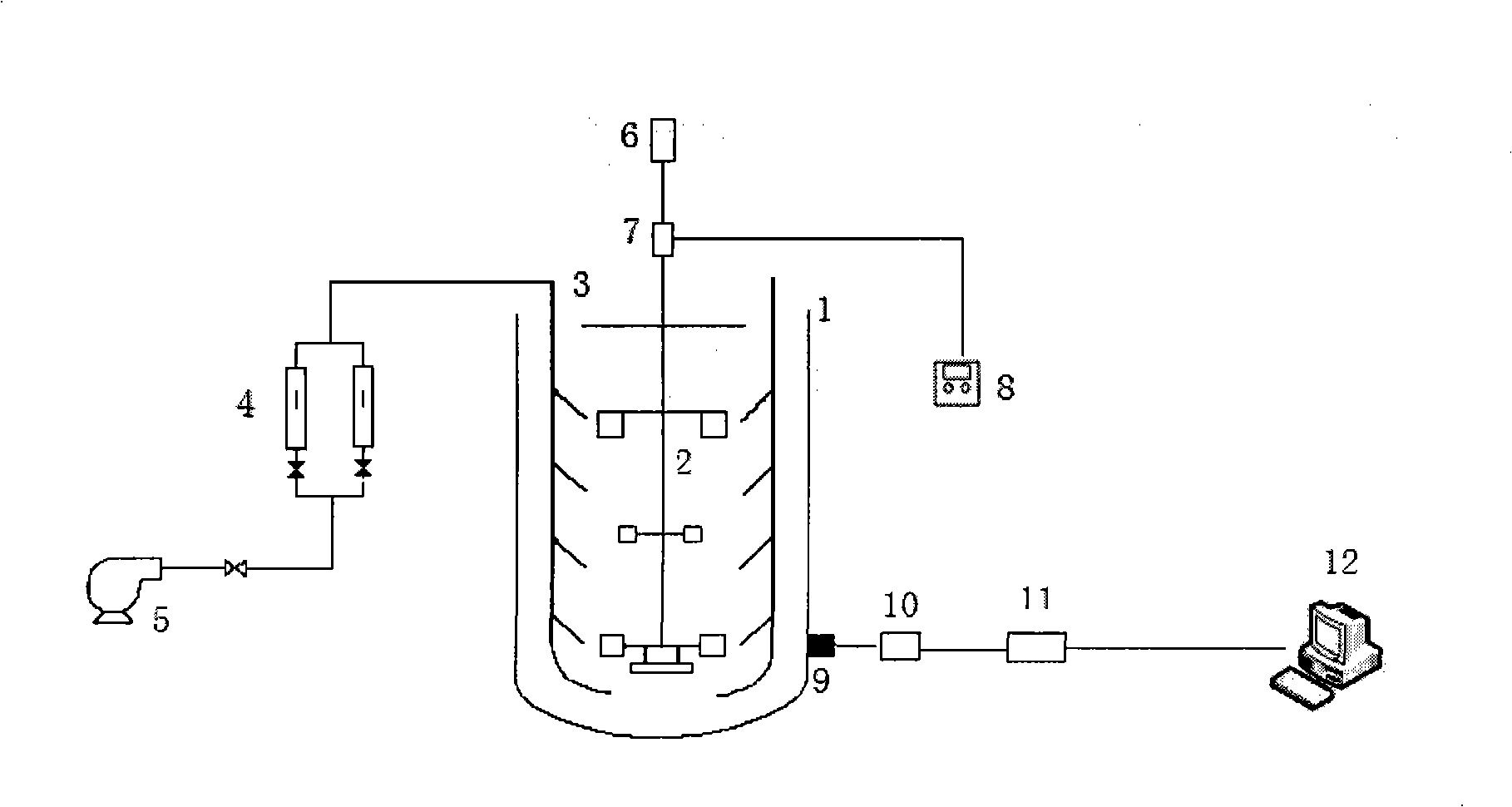

[0030] Gas-liquid mixed system, experimental equipment such as image 3 As shown, measure the rotational speed of the pan point.

[0031] The inner diameter of the stirred tank is 980mm, the material is plexiglass, and the experimental medium is air and water. The impeller is a three-layer six-blade disc turbine with a diameter of 350mm and 600L of water. The test speed is 0.83~3.33r·s -1 , ventilation volume is 0.011~0.028m 3 ·s -1 , The hydrophone probe is set on the outer wall of the stirred tank close to the bottom 1 / 4 of the static liquid level, and the sampling frequency of the vibration signal is 20kHz.

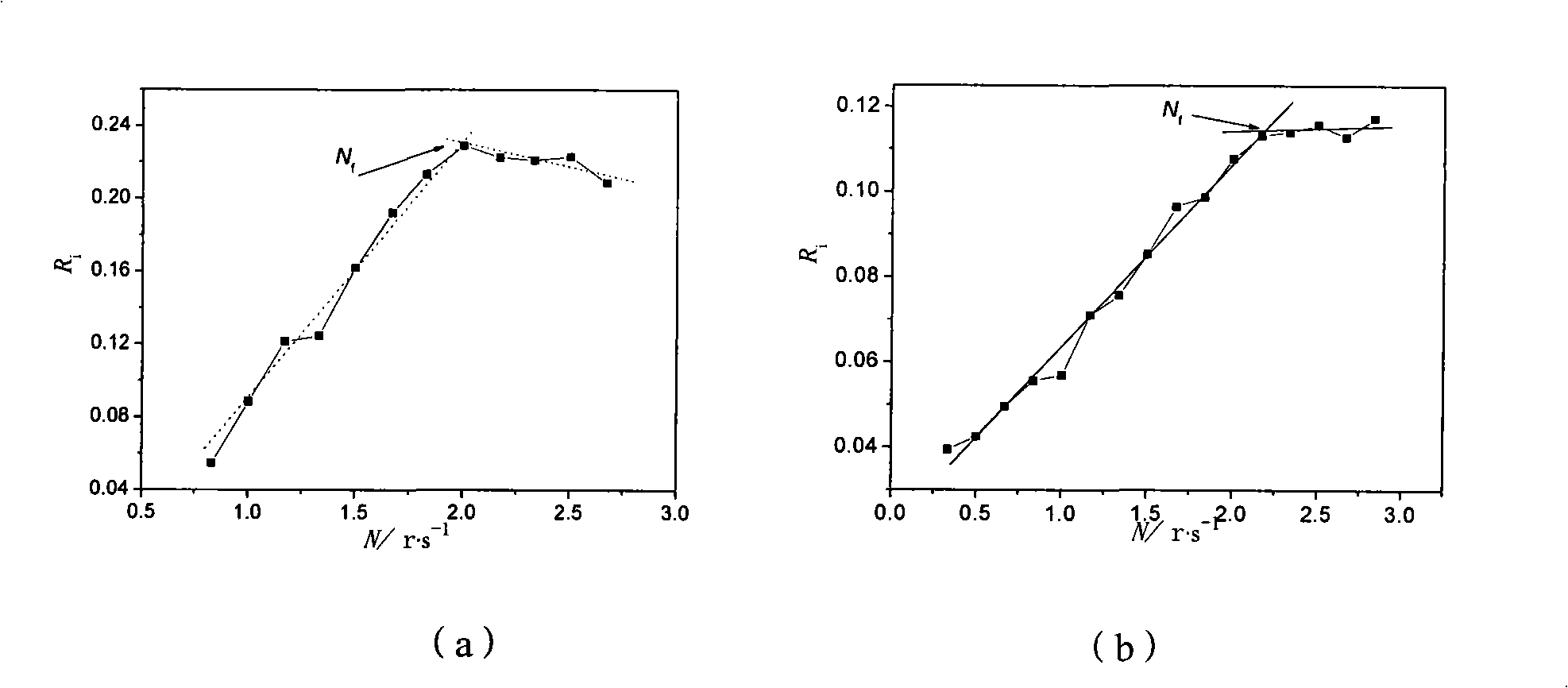

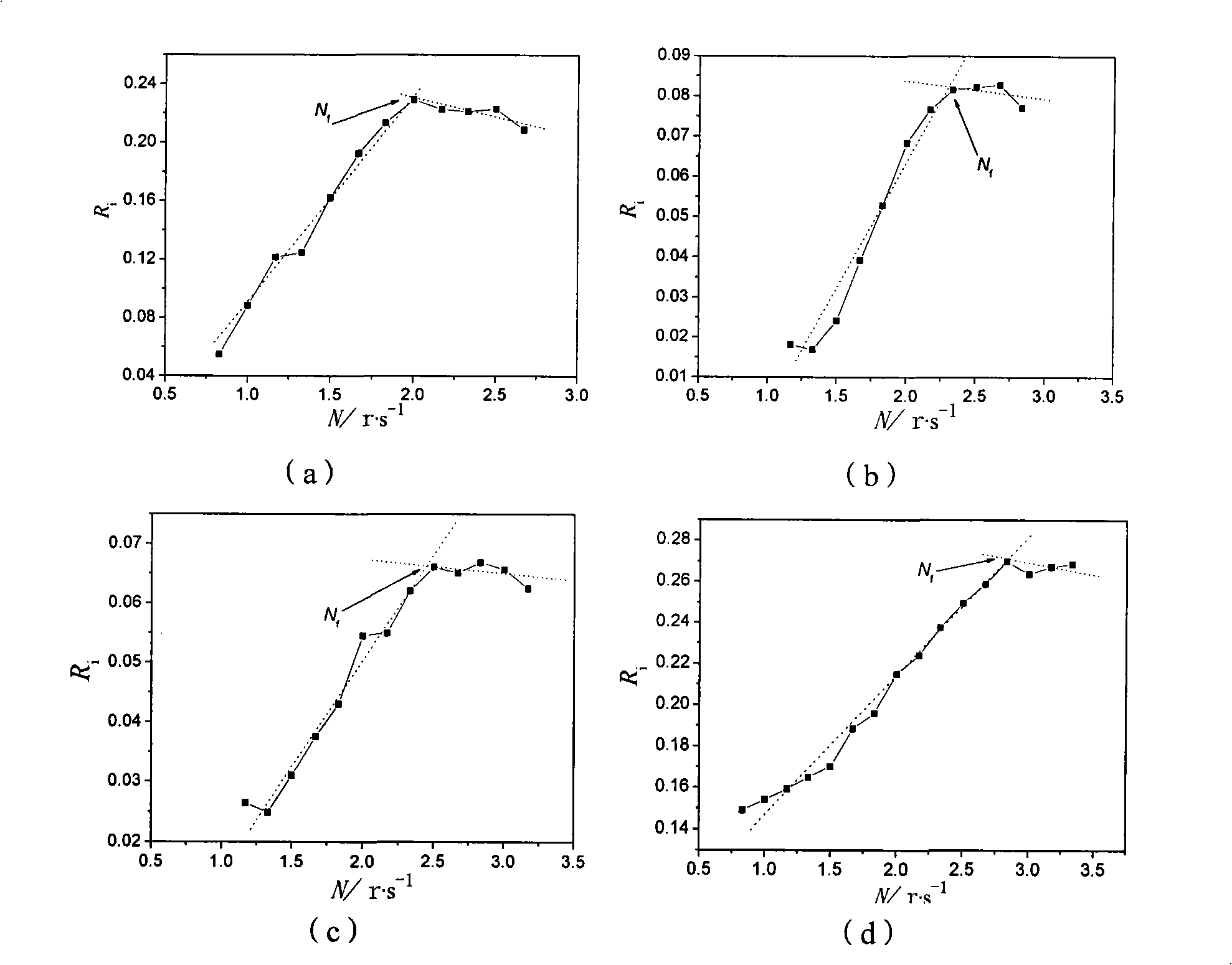

[0032] The collected vibration signal is decomposed by the second-order Daubechies multi-scale wavelet and using R / S fractal technology, the vibration signal in the frequency band with Hurst value less than 0.5 is selected as the energy fraction R of the vibration signal representing the movement of solid particles i . Investigate R i The variation with the stir...

Embodiment 2

[0037] Gas-liquid-solid mixed system, slurry polyethylene pilot plant, measuring flooding point speed, hydrophone probe placed at 2 / 5 of the static liquid level on the outer wall of the stirred tank.

[0038] The volume of the test kettle is 10L, the material is stainless steel, high-purity ethylene is used as the main raw material, a small proportion of propylene or 1-butene is used as the comonomer, hydrogen is used as the molecular weight regulator, hexane is used as the solvent, and tetrachloride is used. Titanium / ethoxymagnesium supported high-efficiency Z-N catalyst reacts at a temperature of 87°C and a pressure of 0.8MPa to produce polyethylene. A gas-liquid-solid three-phase system consisting of ethylene gas, n-hexane solvent and polyethylene solid is formed in the reactor. The stirring paddle is a disc-type turbine paddle with a blade diameter of 30 cm and a sampling frequency of 100 MHz.

[0039] Decompose the obtained signal on multiple scales and use R / S fractal t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com