Surface acoustic wave device and surface acoustic wave oscillator

A surface acoustic wave device and surface acoustic wave technology, applied in electrical components, impedance networks, etc., can solve problems such as errors, no consideration of manufacturing errors, temperature changes, frequency changes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Hereinafter, embodiments of the surface acoustic wave device and the surface acoustic wave oscillator according to the present invention will be specifically described with reference to the drawings.

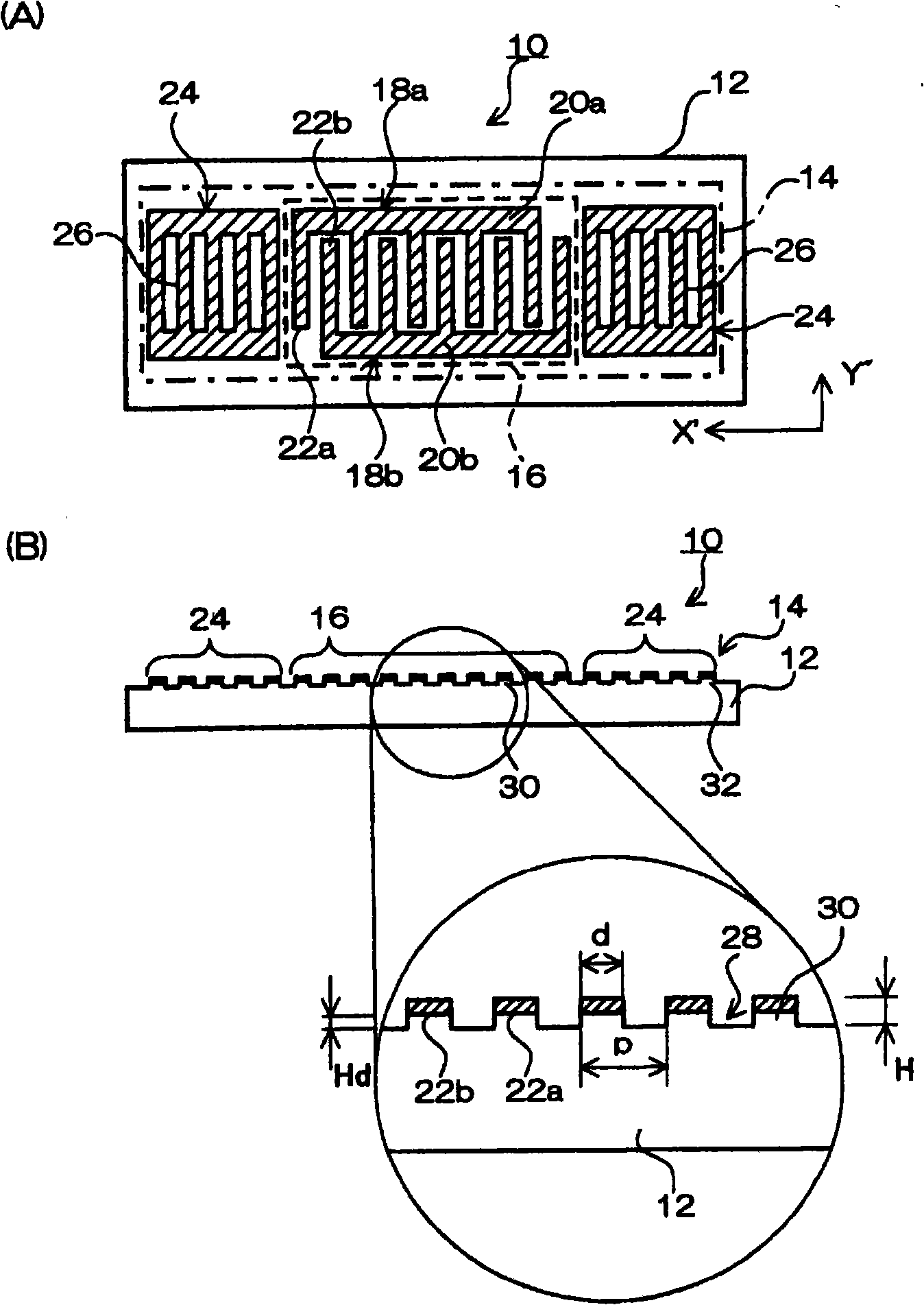

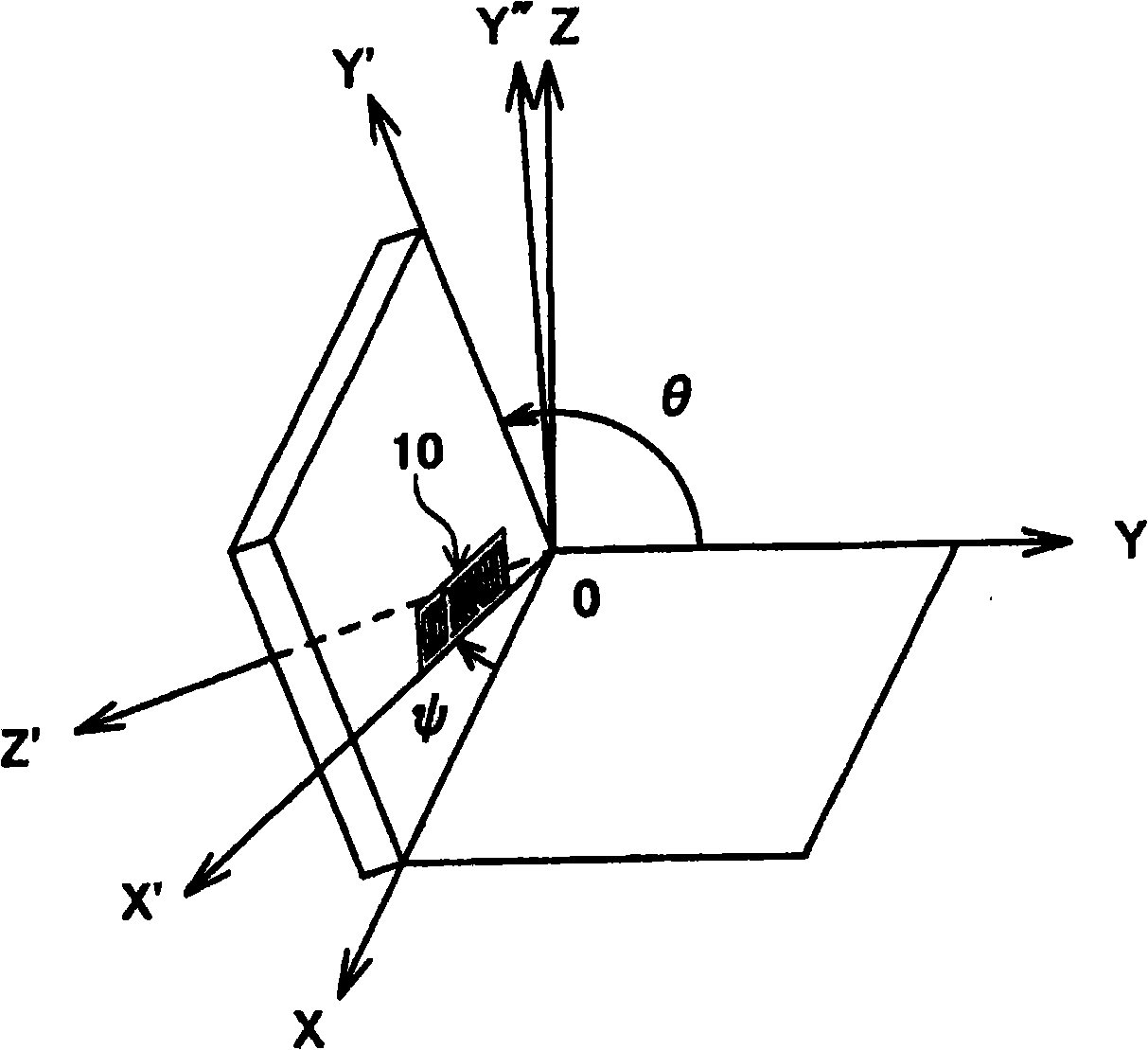

[0041] The surface acoustic wave (SAW: surface acoustic wave) device 10 related to this embodiment is as follows:figure 1 Shown is a vibrator-type surface acoustic wave device based on a piezoelectric substrate 12 , an IDT (interdigital transducer: interdigital transducer) 16 , and a reflector 24 . Piezoelectric substrate 12 such as figure 2 As shown, a crystal substrate in which crystallographic axes are represented by an X-axis (electrical axis), a Y-axis (mechanical axis), and a Z-axis (optical axis) is used.

[0042] The Euler angles are explained here. A substrate represented by Euler angles (0°, 0°, 0°) is a Z-cut substrate having a main surface perpendicular to the Z-axis. Here, the Euler angles of It represents the first rotation of the Z-cut substrate, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com