Preparation method of nanometer platinum doping tungstic oxide with high catalytic activity under visible light

A high catalytic activity, tungsten trioxide technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., to achieve a wide range of applications, high photocatalytic activity, effective utilization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

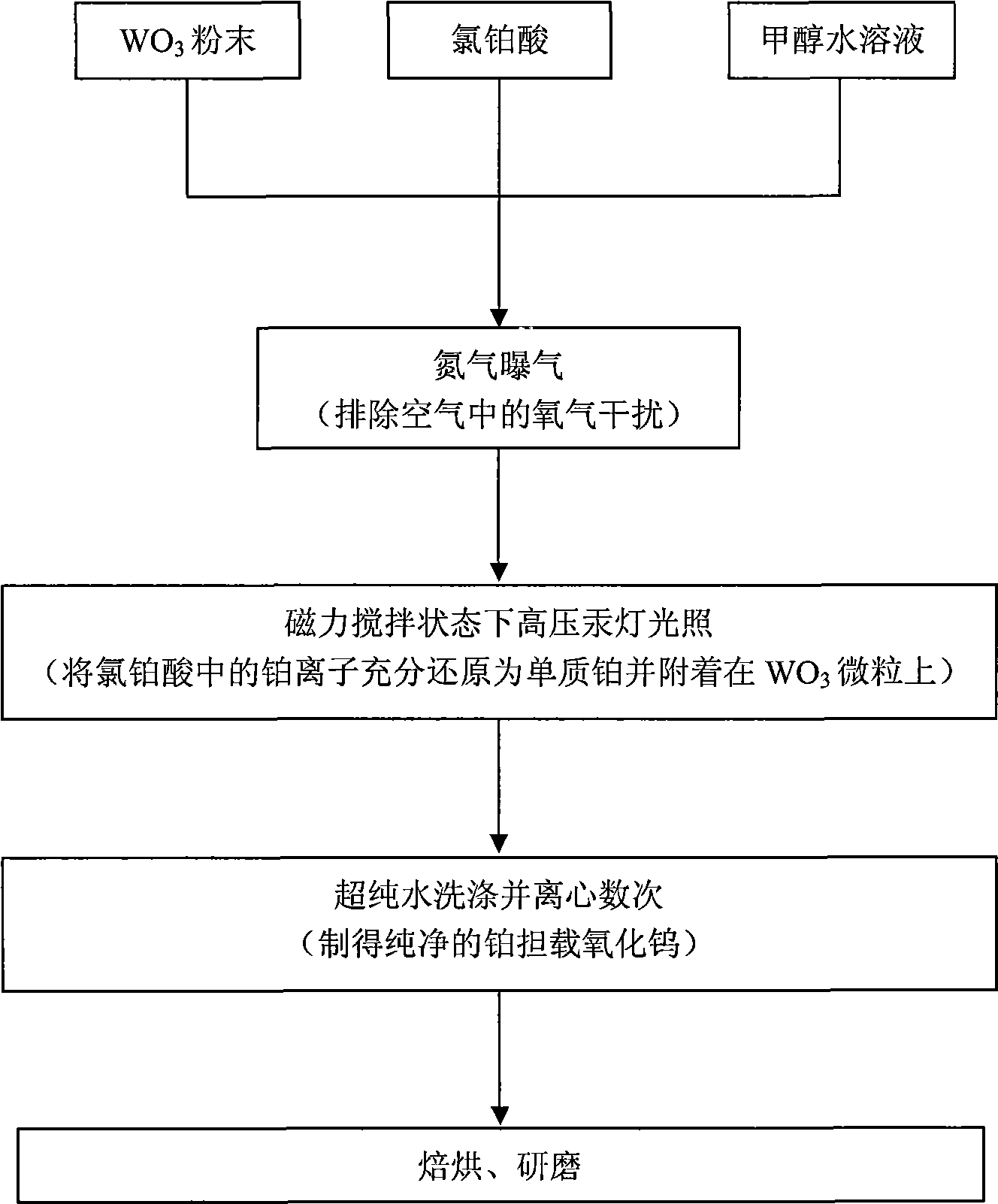

[0018] Embodiment 1, as figure 1 Shown, this example preparation method comprises the following steps:

[0019] 1) Pretreatment of tungsten trioxide particles, using WO 3 To represent,

[0020] Will commercially available WO 3 Weigh 10mg of the particles and add them to 50ml of absolute ethanol. After 0.5h of magnetic stirring at a speed of 500rpm, they are ultrasonically oscillated in an ultrasonic cleaner for 0.5h to increase the dispersion of tungsten oxide particles. Then it was centrifuged at 3000rpm for 5min, and dried in a vacuum oven for 5h at a drying temperature of 20°C. stand-by;

[0021] 2) Preparation of platinum-supported tungsten trioxide, using Pt / WO 3 To represent,

[0022] Weigh 50mg of pretreated WO 3 Add it into a glass test tube, then add 5ml of aqueous methanol solution with a volume ratio of 2:1-1:2 and a chloroplatinic acid solution (H 2 PtCl 6 ·6H 2 O) 10 μl was pipetted into a test tube. A magnetic stirring bar was added, and the magnetic s...

Embodiment 2

[0025] Embodiment 2, as figure 1 Shown, this example preparation method comprises the following steps:

[0026] 1) Pretreatment of tungsten trioxide particles, represented by WO3,

[0027] Will commercially available WO 3 Weigh 300 mg of the particles and add them to 100 ml of methanol, and then magnetically stir at 1000 rpm for 1 hour, and then ultrasonically oscillate for 2 hours in an ultrasonic cleaner to increase the dispersion of tungsten oxide particles. Then centrifuge at 8000rpm for 15min, and dry in a vacuum oven for 20h at a drying temperature of 100°C. stand-by;

[0028] 2) Preparation of platinum-supported tungsten trioxide, using Pt / WO 3 To represent,

[0029] Weigh 200mg of pretreated WO 3 Add it into a glass test tube, then add 20ml of methanol aqueous solution with a volume ratio of 2:1-1:2 and a chloroplatinic acid solution (H 2 PtCl 6 ·6H 2 O) 200 μl was pipetted into a test tube. A magnetic stirring bar was added, and the magnetic stirring was per...

Embodiment 3

[0032] Embodiment 3, as figure 1 Shown, this example preparation method comprises the following steps:

[0033] 1) Pretreatment of tungsten trioxide particles, using WO 3 To represent,

[0034] Will commercially available WO 3 Weigh 150mg of the particles and add them to 75ml of isopropanol. After magnetic stirring at 750rpm for 0.75h, then ultrasonically vibrate for 1.25h in an ultrasonic cleaner to increase the dispersion of tungsten oxide particles. Then it was centrifuged at 5500rpm for 10min, and dried in a vacuum oven for 12h at a drying temperature of 60°C. stand-by;

[0035] 2) Preparation of platinum-supported tungsten trioxide, using Pt / WO 3 To represent,

[0036] Weigh 125mg of pretreated WO 3 Add in the glass test tube, then the methanol aqueous solution 12ml that the volume ratio is 2:1-1:2 and the chloroplatinic acid solution (H 2 PtCl 6 ·6H 2 O) 105 μl was pipetted into a test tube. A magnetic stirring bar was added, and the magnetic stirring was perf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com